|

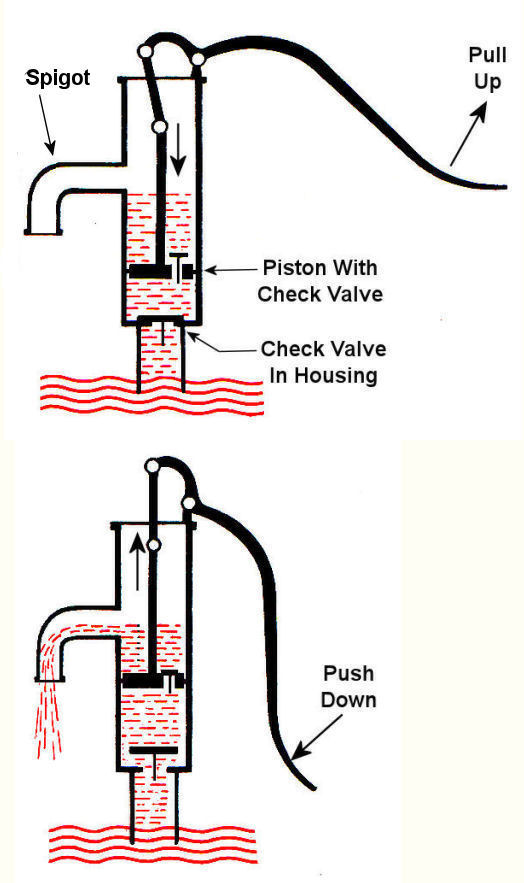

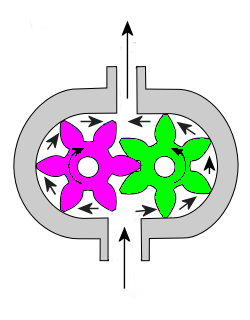

Pumps are all around us. They keep our drinking water flowing, the cooling water circulating in your car’s engine, and even your blood flowing. They’re essential in many aspects of our lives, but most of us don’t think too much about them. For our discussion let’s put them into two categories: positive displacement pumps and centrifugal pumps. This week, we’ll focus on positive displacement pumps. Positive displacement pumps, as their name implies, displace a quantity of liquid with each complete cycle of movement. This takes place when moving parts of the pump take “bites” out of the liquid at the inlet, then force them to exit through the outlet. A familiar example of a positive displacement pump is the type of hand operated water pump that’s commonly found in campgrounds. See Figure 1. Figure 1 – A Positive Displacement Pump This type of pump is known as a reciprocating positive displacement pump. By reciprocating, I mean that the moving parts travel back and forth in a straight line during its operation. Let’s see how it works by referring to the cutaway view in Figure 2. Figure 2 – Cutaway View of the Pump Shown in Figure 1 In the cutaway view, the pump’s piston and internal check valve are shown, and there’s another check valve in the bottom of the pump housing. When you pull up on the handle, the piston moves down into the water in the pump housing, and the pressure caused by this movement forces the check valve in the bottom to slam closed, while the check valve above is forced open. This causes water movement to flood through the open check valve and fill up the space above the piston. When you push down on the handle, the opposite happens. The piston is made to move upward. The upward acceleration of the water above the piston causes the check valve on the piston to slam shut, and this traps the water above it. As the piston moves back up, a suction is created below, which causes the check valve in the bottom of the housing to pop open and more water is drawn up into the space below the piston. Eventually, when the piston gets high enough, the water trapped on top of it will flow out of the spigot. Another type of positive displacement pump is represented by a rotary pump. These pumps operate in a circular motion to move a volume of liquid with each revolution of the pump shaft. This is done by trapping liquid between moving parts, such as gears, lobes, vanes, or screws, and the stationary pump housing itself. To show how this works, refer to the gear pump shown in Figure 3. Its gear teeth mesh together in the middle of the pump, blocking the flow from going straight through and trapping it within the spaces formed by rotating gear teeth and the pump housing. It’s like the water is being forced through a turnstile.

Figure 3 – A Cutaway View of a Gear Pump Next week, we’ll talk about centrifugal pumps and how they move liquids along using centrifugal force.

_____________________________________________

|

Engineering Expert Witness Blog

Published by Philip J. O'Keefe, PE, MLE