|

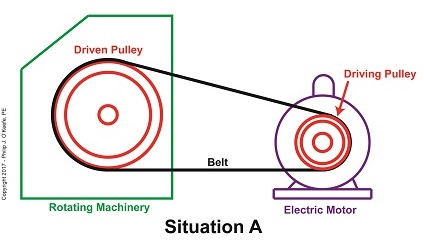

Soon after the first pulleys were used with belts to transmit mechanical power, engineers such as Leonhard Euler and Johann Albert Eytelwein discovered that the diameter of the pulleys used determined the speed at which they rotated. This allowed for a greater diversity in mechanical applications. We’ll set up an examination of this phenomenon today. Last time we introduced this basic mechanical power transmission system consisting of a driving pulley, a driven pulley, and a belt, which we’ll call Situation A. A Driven Pulley’s Larger Diameter Determines a Slower Speed

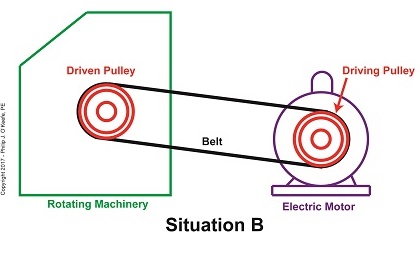

In this situation, the rotating machinery’s driven pulley diameter is larger than the electric motor’s driving pulley diameter. The result is the driven pulley turns at a slower speed than the driving pulley. Now let’s say we need to speed the rotating machinery up so it produces more widgets per hour. In that case we’d make the driven pulley smaller, as shown in Situation B. A Driven Pulley’s Smaller Diameter Determines a Faster Speed

With the smaller diameter driven pulley, the rotating machinery will operate faster than it did in Situation A. Next week we’ll introduce the Pulley Speed Ratio Formula, which mathematically defines this phenomenon. Copyright 2017 – Philip J. O’Keefe, PE Engineering Expert Witness Blog ____________________________________ |