| Last week our kitchen ceiling fan and light combo decided to stop working. We don’t like eating in the dark, so I was compelled to do some immediate troubleshooting. As an engineer with training in the workings of electricity I have a great respect for it. I’m well aware of potential hazards, and I took a necessary precaution before taking things apart and disconnecting wires. I made the long haul down the stairs to the basement, opened the circuit breaker in the electrical panel, and disabled the flow of electricity to the kitchen. My fears of potential electrocution having been eliminated, my only remaining fear was of tumbling off the ladder while servicing the fan.

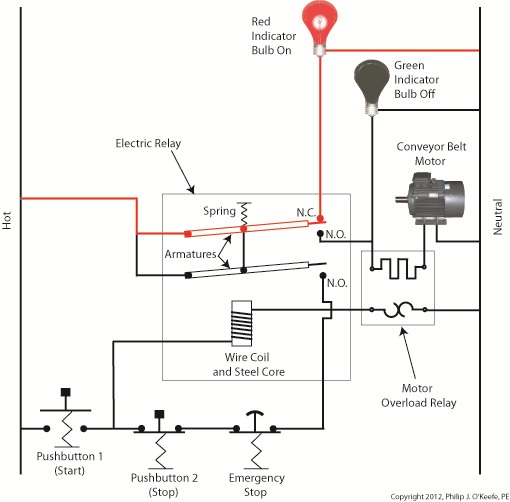

Just as I took the precaution to disconnect the power supply before performing electrical maintenance in my home, workers in industrial settings must do the same, and a chief player in those scenarios is the motor overload relay discussed last week. It automatically shuts down electric motors when they become overheated. Let’s revisit that example now. Figure 1

Our diagram in Figure 1 shows electric current flowing through the circuit by way of the red path. Even if this line were shut down, current would continue to flow along the path, because there is no means to disconnect the entire control system from the hot and neutral lines supplying power to it, that is, it is missing disconnect switches. Electric current will continue to pose a threat to workers were they to attempt a repair to the system. Now let’s see how we can eliminate potential hazards on the line. Figure 2

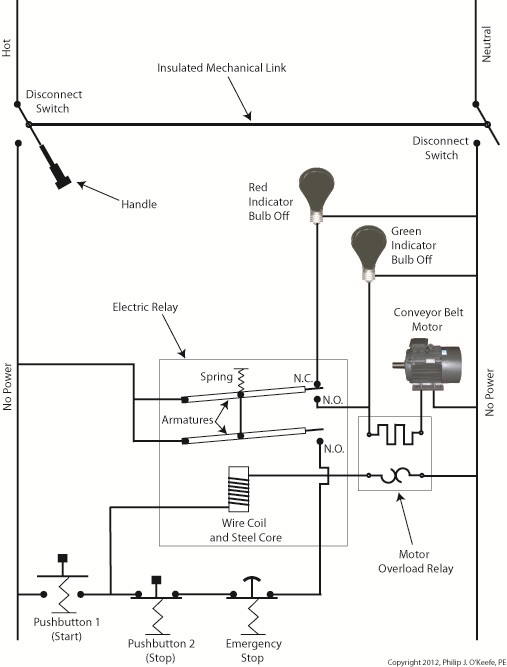

In Figure 2 there is an obvious absence of the color red, indicating the lack of current within the system. We accomplished this with the addition of disconnect switches capable of isolating the motor control circuitry, thereby cutting off the hot and neutral lines of the electrical power supply and along with it the unencumbered flow of electricity. These switches are basically the same as those seen in earlier diagrams in our series on industrial controls, the difference here is that the two switches are tied together by an insulated mechanical link. This link causes them to open and close at the same time. The switches are opened and closed manually via a handle. When the disconnect switches are both open electricity can’t flow and nothing can operate. Under these conditions there is no risk of a worker coming along and accidentally starting the conveyor motor. To add yet another level of safety, disconnect switches are often tagged and locked once de-energized. This prevents workers from mistakenly closing them and starting the conveyor while maintenance is being performed. Brightly colored tags alert everyone that maintenance is taking place and the switches must not be closed. The lock that performs this safety function is actually a padlock. It’s inserted through a hole in the switch handle, making it impossible for anyone to flip the switch. Tags and locks are usually placed on switches by maintenance personnel before repairs begin and are removed when work is completed. Now let’s see how our example control system looks in ladder diagram format. Figure 3

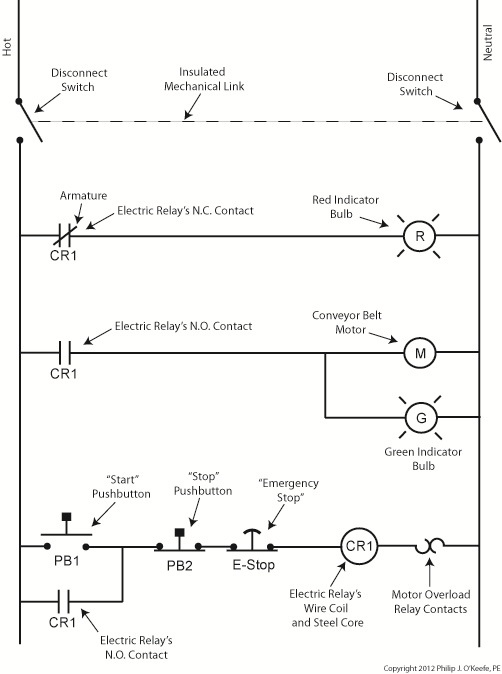

Figure 3 shows a ladder diagram that includes disconnect switches, an emergency stop button, and the motor overload relay contacts. The insulated mechanical link between the two switches is represented by a dashed line. Oddly enough, engineering convention has it that the motor overload relay heater is typically not shown in a ladder diagram, therefore it is not represented here. This wraps up our series on industrial control. Next time we’ll begin a discussion on mechanical clutches and how they’re used to transmit power from gasoline engines to tools like chainsaws and grass trimmers. ____________________________________________

|

Posts Tagged ‘industrial control system’

Food Manufacturing Challenges – HACCP Design Principle No. 3

Sunday, October 30th, 2011| How do parents make life safer and healthier for their kids? One of the ways is to impose limits on things like roaming distance within the neighborhood, curfews, and insisting that you eat your vegetables. Just common sense, right? Let’s take a look at some more of it.

Limits are also necessary within the food manufacturing industry. Let’s take a look at Hazard Analysis and Critical Control Point (HACCP) Principle No. 3 to see how they’re established and why. Principle 3: Establish critical limits for each critical control point. – You can think of a critical limit as a boundary of safety for each critical control point (CCP). So how do you determine that boundary of safety? It’s difficult to generalize, but if you’ve ever watched the TV show Hoarders, you have an excellent example of one that has not only been breeched, but torn asunder. In order to prevent things in the commercial food industry from getting anywhere near Hoarders bad, maximum and minimum values are set in place, representing safeguards to physical, biological, and chemical parameters at play within the industry. Critical limits can be obtained from regulatory standards and guidelines, scientific literature, experimental studies, as well as information provided by consultants. These critical limits come into play with issues as varied as machine design, raw material temperatures, and overall safe processing times. How could the hoarders let things get so bad? If you listen carefully, you’ll hear bits of information that provide a clue. They’ll say it started with a few things falling to the floor which they didn’t feel like picking up and it escalated from there. Now all of us live within environments which differ as to their cleanliness, but by and large we live within space where we feel comfortable and consider to be reasonably clean. We don’t all habitually move stoves and refrigerators to clean, for example. But if we were so inclined, refrigerators do come with front access panels that are easily removed. Trouble is the space they provide access to often isn’t large enough to accommodate hands and a vacuum cleaner nozzle comfortably. You can imagine how frustrating and potentially dangerous it would be to public health to have commercial machinery that provided such limited access for cleaning. To cope with this problem design engineers institute minimum and maximum parameters, such as in the critical limit dimensions of a removable cover. Their guideline would ensure that enough space is provided so that personnel can fully access all aspects of machinery with tools for cleaning. That same cover can also have established maximum critical limits, so that dimensions aren’t too large and heavy to be manipulated by hand. Human nature being what it is, something that is too difficult to remove may be “forgotten” and parts of the machine may never get cleaned. Raw meats and many produce can contain hazards like salmonella, E. coli, and other nasty critters that are dangerous to human health. One of the ways the commercial food industry works to ensure that these contaminants aren’t unleashed on the public is to install programmable control systems into processing machinery that essentially cooks the meat at an established minimum temperature for a minimum amount of time. Utilizing this type of temperature control in conjunction with an established maximum cooking parameter for temperature and time will virtually eliminate the possibility of overcooked or burnt food products. When you buy that frozen dinner in most cases it’s completely cooked, but it’s a rarity to find it’s been burned. Another situation in which critical limits are utilized is in the maintenance of machinery, such as when they limit the number of hours a machine can be operated before it is shut down for servicing. Next week we’ll move on to Principle No. 4 and see how it establishes monitoring requirements for each CCP. ____________________________________________ |