Posts Tagged ‘injury’

Monday, April 2nd, 2012

| I remember the days when trimming grass around trees, fences, and flower beds involved the use of hand operated clippers. You know, those scissor-like things that require you to squeeze the handles together to move the blades. Cutting seemed to take forever and there was a lot of bending, stooping, and kneeling which would kill your back and turn your knees green from grass stains. Worst of all, the repetitive motion of squeezing the handles dozens of times would cramp your hands. It was a great day when gasoline powered grass trimmers came along. Just pull the recoil starter cord and you’re ready to go. It’s fast, easy, and the final result looks better too.

If you’ve ever operated a gasoline powered tool like a grass trimmer, you probably noticed that the cutter action isn’t immediate once the engine is started. Instead, the engine enters into a much slower initial speed mode, the idle speed. The cutter moves only after the throttle trigger is depressed. This introduces more gas to the engine, causing it to speed up, and this action is due to a device called the centrifugal clutch.

A centrifugal clutch, or any type of clutch for that matter, serves one basic function, to physically disconnect, then reconnect a gasoline engine from whatever it is powering. For example, if the engine in a weed trimmer stayed permanently connected to the cutter when the engine was started, it would pose a definite safety hazard. Even at idle speed, the cutter would immediately kick into high speed operational mode, and if someone wasn’t prepared for this instant response there would be a good probability of injury.

When a centrifugal clutch is placed between the engine and the cutter, it automatically disconnects the engine from the cutter during starting and at idle speed. We’ll see how it does that in a later blog. For now, let’s consider the fact that the idle function serves as a “get ready.” The user is able to both psychologically and physically prepare themselves to use their tool. Pressing the trigger revs the engine up and causes the centrifugal clutch to connect the engine to the cutting action. When the operator takes their finger off the throttle trigger the engine returns to idle speed, and the clutch automatically disconnects the engine from the cutter. The cutter becomes idle.

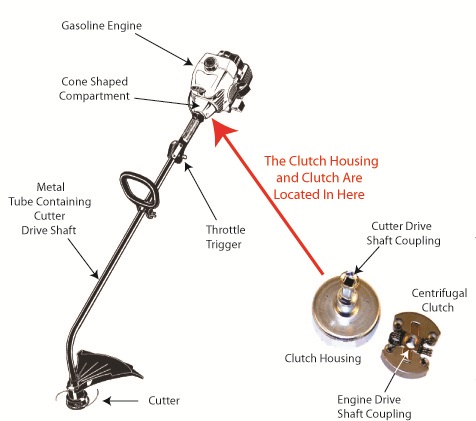

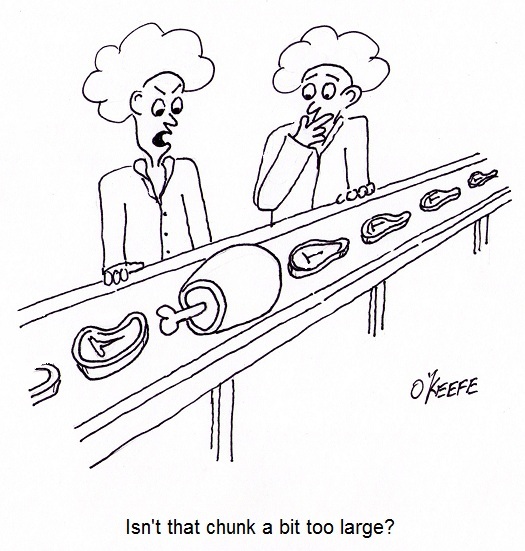

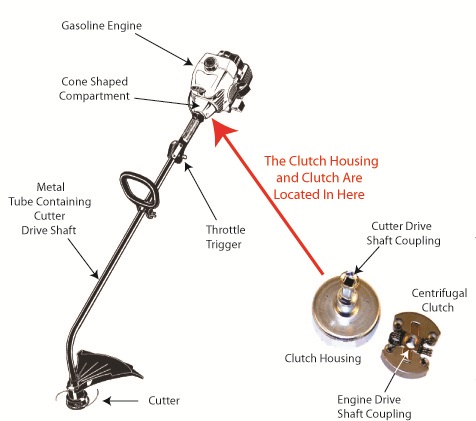

Figure 1

Figure 1 shows a gas trimmer and its centrifugal clutch. The engine is on one end of the trimmer and the cutter at the other. A hollow metal tube runs between them. This tube contains the cutter drive shaft. The centrifugal clutch and its clutch housing are located in a cone shaped compartment between the engine and the metal tube. The clutch is connected to the engine drive shaft and the clutch housing is connected at the other end of the cutter drive shaft. When they’re assembled into the grass trimmer, the clutch fits within the clutch housing.

Next time we’ll see how the centrifugal clutch on a grass trimmer uses centrifugal force and friction to automatically transmit mechanical power from the gas engine to the cutter.

____________________________________________

|

Tags: centrifugal clutch, clutch, clutch housing, cutter, cutter drive shaft, drive shaft, engine drive shaft, engineering expert witness, forensic engineer, friction, gasoline powered grass trimmer, grass trimmer, hand held gasoline powered tool, hollow metal tube, idle speed, injury, mechanical power transmission, recoil starter, safety hazard, throttle trigger, weed trimmer, weed wacker

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on Mechanical Power Transmission – Centrifugal Clutches

Sunday, March 25th, 2012

| Last week our kitchen ceiling fan and light combo decided to stop working. We don’t like eating in the dark, so I was compelled to do some immediate troubleshooting. As an engineer with training in the workings of electricity I have a great respect for it. I’m well aware of potential hazards, and I took a necessary precaution before taking things apart and disconnecting wires. I made the long haul down the stairs to the basement, opened the circuit breaker in the electrical panel, and disabled the flow of electricity to the kitchen. My fears of potential electrocution having been eliminated, my only remaining fear was of tumbling off the ladder while servicing the fan.

Just as I took the precaution to disconnect the power supply before performing electrical maintenance in my home, workers in industrial settings must do the same, and a chief player in those scenarios is the motor overload relay discussed last week. It automatically shuts down electric motors when they become overheated. Let’s revisit that example now.

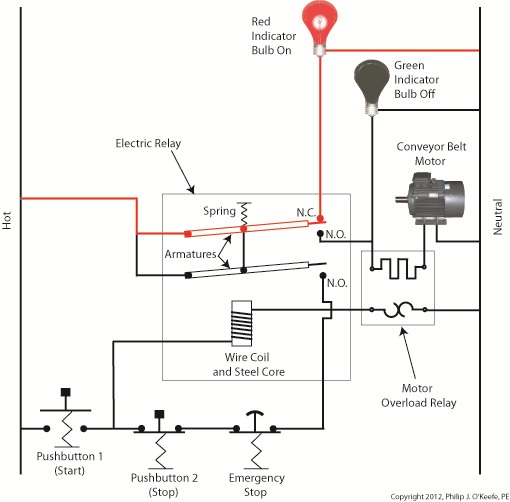

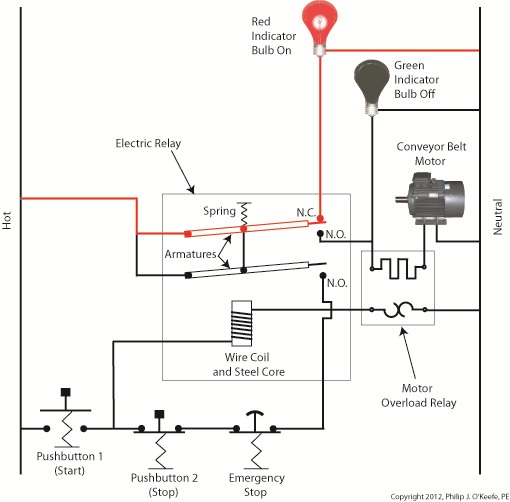

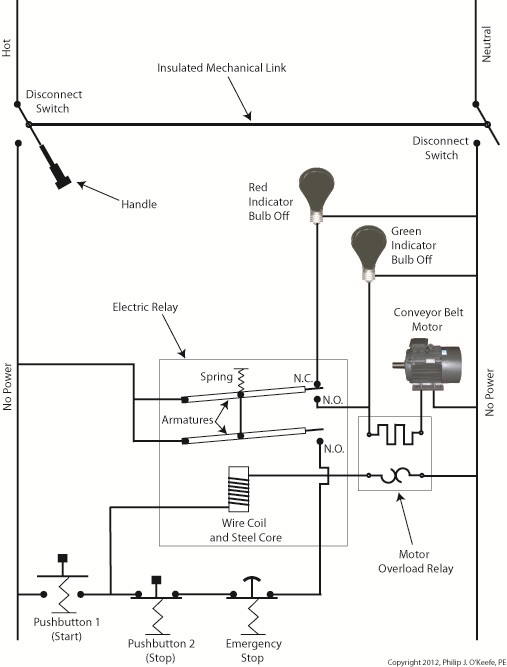

Figure 1

Our diagram in Figure 1 shows electric current flowing through the circuit by way of the red path. Even if this line were shut down, current would continue to flow along the path, because there is no means to disconnect the entire control system from the hot and neutral lines supplying power to it, that is, it is missing disconnect switches. Electric current will continue to pose a threat to workers were they to attempt a repair to the system. Now let’s see how we can eliminate potential hazards on the line.

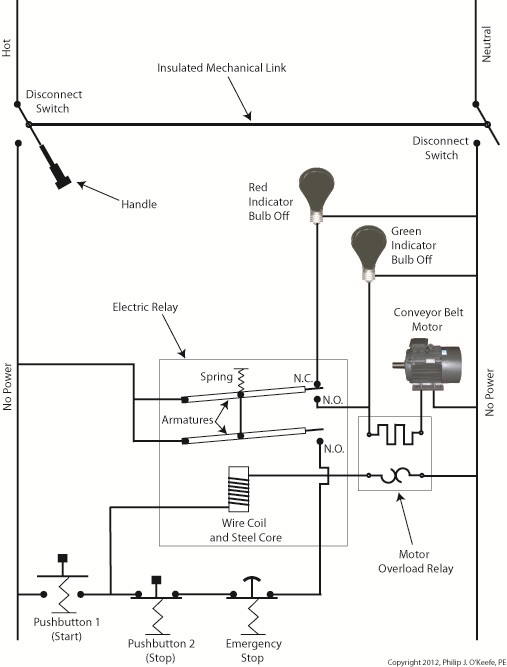

Figure 2

In Figure 2 there is an obvious absence of the color red, indicating the lack of current within the system. We accomplished this with the addition of disconnect switches capable of isolating the motor control circuitry, thereby cutting off the hot and neutral lines of the electrical power supply and along with it the unencumbered flow of electricity.

These switches are basically the same as those seen in earlier diagrams in our series on industrial controls, the difference here is that the two switches are tied together by an insulated mechanical link. This link causes them to open and close at the same time. The switches are opened and closed manually via a handle. When the disconnect switches are both open electricity can’t flow and nothing can operate. Under these conditions there is no risk of a worker coming along and accidentally starting the conveyor motor.

To add yet another level of safety, disconnect switches are often tagged and locked once de-energized. This prevents workers from mistakenly closing them and starting the conveyor while maintenance is being performed. Brightly colored tags alert everyone that maintenance is taking place and the switches must not be closed. The lock that performs this safety function is actually a padlock. It’s inserted through a hole in the switch handle, making it impossible for anyone to flip the switch. Tags and locks are usually placed on switches by maintenance personnel before repairs begin and are removed when work is completed.

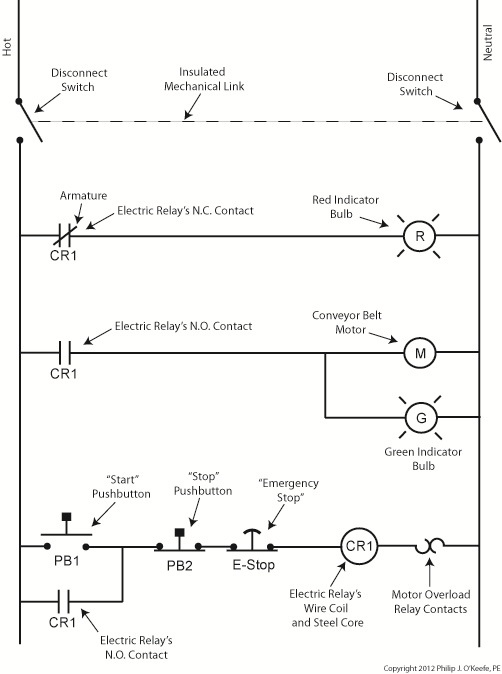

Now let’s see how our example control system looks in ladder diagram format.

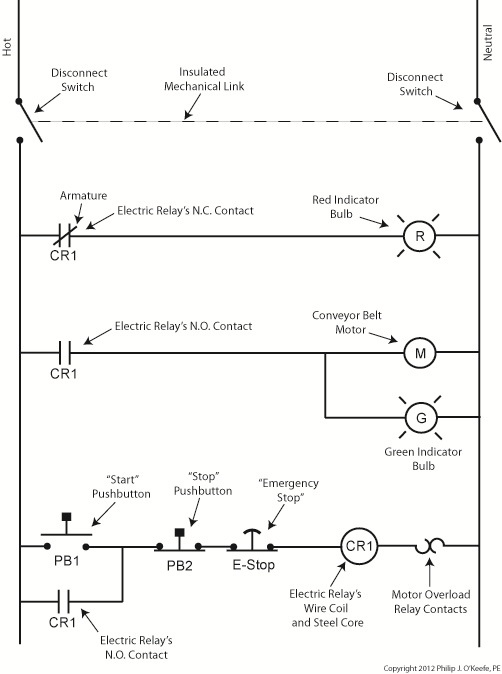

Figure 3

Figure 3 shows a ladder diagram that includes disconnect switches, an emergency stop button, and the motor overload relay contacts. The insulated mechanical link between the two switches is represented by a dashed line. Oddly enough, engineering convention has it that the motor overload relay heater is typically not shown in a ladder diagram, therefore it is not represented here.

This wraps up our series on industrial control. Next time we’ll begin a discussion on mechanical clutches and how they’re used to transmit power from gasoline engines to tools like chainsaws and grass trimmers.

____________________________________________

|

Tags: chainsaw, circuit breaker, circuitry, clutch, control panel, conveyor belt, current flow, death, disconnect switch, electric motor, electric relay, electrical maintenance, electrical panel, electricity, electrocution, emergency stop, engineering expert witness, forensic engineer, hot, indicator bulbs, industrial control system, injury, lawn trimmer, lock, lockout tag out, maintenance worker, motor overheated, neutral, overload relay, overload relay heater, potential hazards, power supply, pushbutton, safety, safety hazard, tag, troubleshooting, wires

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability, Professional Malpractice | Comments Off on Industrial Control Basics – Disconnect Switches

Sunday, November 6th, 2011

| Imagine going on a diet and not having a scale to check your progress, or going to the doctor and not having your temperature taken. Feedback is important in our daily lives, and industry benefits by it, too.

Generally speaking, feedback, or monitoring, is a tool that provides relevant information on a timely basis as to whether things are working as they were intended to. It’s an indispensable tool within the food manufacturing industry. Without it, entire plants could be erected exposing workers to injury and consumers to bacteria-laden products. It’s just plain common sense to monitor activities all along the way, starting with the design process. Now let’s see how monitoring is applied in HACCP Design Principle No. 4.

Principle 4: Establish critical control point monitoring requirements. – Monitoring activities are necessary to ensure that the critical limits established at each critical control point (CCP) established under Principle 3 discussed last week are working as intended. In other words, if the engineer identifies significant risks in the design of a piece of food processing equipment and establishes critical limits at CCPs to eliminate the risk, then the CCPs must be monitored to see if the risk has actually been eliminated.

Monitoring can and should be performed in food manufacturing plants by a variety of personnel, including design engineers, the manager of the engineering department, production line workers, maintenance workers, and quality control inspectors. For example, engineering department procedures in a food manufacturing plant should require the engineering manager to monitor CCPs established by the staff during the design of food processing equipment and production lines. Monitoring would include reviewing the design engineer’s plans, checking things like assumptions made concerning processes, calculations, material selections, and proposed physical dimensions.

In short, monitoring should be a part of nearly every process, starting with the review of design documents, mechanical and electrical drawings, validation test data for machine prototypes, and technical specifications for mechanical and electrical components. This monitoring would be conducted by the engineering manager during all phases of the design process and before the finished equipment is turned over to the production department to start production.

To illustrate, suppose the engineering manager is reviewing the logic in a programmable controller for a cooker on a production line. She discovers a problem with the lower critical limits established by her engineer at a CCP in the design of a cooker temperature control loop. You see, the time and temperature in the logic is sufficient to thoroughly cook smaller cuts of meat in most of the products that will be made on the line, however the larger cuts will be undercooked. The time and temperature settings within the logic are insufficient to account for the difference.

This situation illustrates the fact that monitoring does no good unless feedback is provided with immediacy. In our example, the design engineer who first established the CCP and the critical limits was not informed in a timely manner of the difference in cooking times that different size meats would require, resulting in the writing of erroneous software logic. Fortunately, continued monitoring by the engineering manager caught the error, leading her to provide feedback about it to the design engineer, who can then make the necessary corrections to the software.

Next week we’ll see what design engineers do with the feedback they’ve received, as seen through the eyes of HACCP Principle 5, covering the establishment of corrective actions.

____________________________________________

|

Tags: bacteria, bacteria-laden products, calculations, CCP, contamination, contoller, critical control point, critical limits, design documents, design engineer, engineering drawings, engineering expert witness, engineering manager, FDA, feedback, food equipment, food manufacturing, food plant, food processing equipment design, food production line, food safety, forensic engineer, HACCP, HACCP Principle 4, Hazard Analysis and Critical Control Point, injury, material selection, meat, monitoring, process control, programmable controller, risk elimination, temperature control, temperture, time, timer, validation testing

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on Food Manufacturing Challenges – HACCP Design Principle No. 4

Sunday, March 7th, 2010

|

Last week we wrapped up our discussion on heat transfer. This week we’ll turn to a discussion on vibration analysis.

Vibration occurs when there is physical movement of a machine part when compared to a point of reference. This physical movement can manifest in a straight line, a circle, or any way imaginable in three dimensions. The point of reference can be a guideway for a sliding part or a shaft for a rotating part.

As discussed in kinetics, machine parts have mass, and when mass moves it contains kinetic energy, so it makes sense that when a part moves within a machine, the energy created can result in forces that act upon the machine as a whole. The net result is machine vibration which occurs in “sympathy” with the movement of the original mechanical part under discussion.

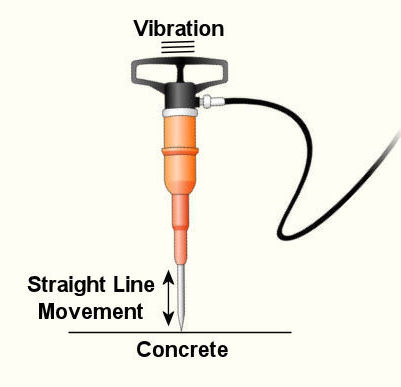

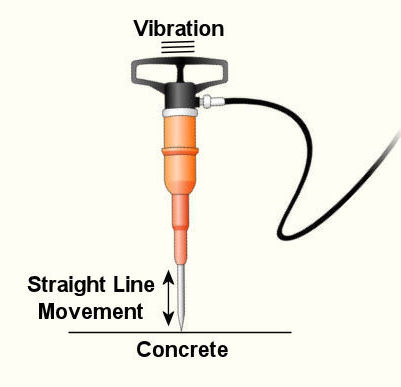

Let’s talk about examples of vibration caused by straight line and circular motion. And what figure conjures up a better image of up-and-down straight line vibration then a jackhammer, as shown in Figure 1. This tool has a chisel which is attached to an air piston that moves up and down in a straight line, and the chisel and piston each have mass. It is the rapid up and down movement of the total mass of the device that results in concrete-breaking force. Unfortunately, those forces also vibrate back up the jackhammers shaft into the hands, arms and body of the construction worker operating it.

Figure 1 – A Jackhammer

An example of vibration caused by circular movement can be found in your washing machine. Ever notice what happens when you throw one heavy object, say a throw rug, into it, and it begins the spin cycle? That “THUMP-THUMP-THUMP” sound that just won’t quit is due to the rug, now wet and congealed into a single heavy lump to one side of the agitator. It continues to spin about the center of the agitator, creating an unbalanced outward centrifugal force that keeps changing direction around its central pivot point, the agitator. This force makes the washing machine want to rock from side to side and front to back. Now imagine this situation taking place inside your washer day after day, hour after hour, every time you put a load to wash. How long do you think your washer would last under this usage? As this example illustrates, vibrations must be considered in machine design because if they are severe enough, they can cause machine parts to prematurely wear and fail.

Speaking of wear and failure, you might have discovered how the tires on your car wore out prematurely and a mechanic said this happened because your shock absorbers or struts are bad. Shock absorbers and struts help to safely control, or “dampen,” vibrations in the suspension system that result when your car’s wheels roll down the highway. Without proper damping, the vibration forces can cause your tire to literally bounce down the road and grind on the pavement with each landing. Oh, yes, if the vibration is strong enough, you can even lose control of your car and end up in a crash.

Unfortunately, strong vibrations do not only affect machinery, but the people that come into contact with them, often causing physical discomfort and injury. Ever heard of “white finger syndrome,” otherwise known as Raynaud’s syndrome? This painful condition, which results when vibrations impair blood flow to the fingers, causes them to tingle, feel numb, and then turn white. The longer a person uses a vibrating tool, and the faster the tool vibrates, the greater the risk.

Well that’s our initial plunge into the world of vibrations. Now that we know the basics of what vibrations are and what they can do, next time we can explore how to resolve a straightforward vibration problem which often presents itself in rotating mechanisms.

_________________________________________________________________

|

Tags: centrifugal force, damping, engineering expert witness, injury, kinetics, mechanical engineering, Raynaud’s syndrome, vibration analysis, vibration force, white finger syndrome

Posted in Engineering and Science | Comments Off on Vibration Analysis in Mechanical Engineering, Part I