Archive for the ‘Forensic Engineering’ Category

Monday, September 4th, 2017

|

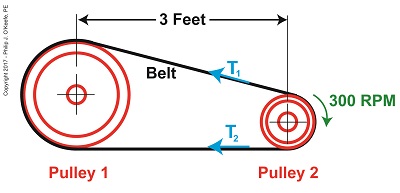

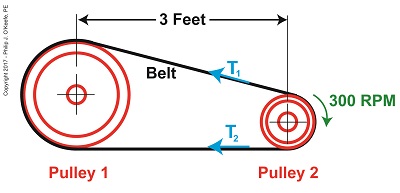

We’ve been working our way towards developing values for variables in our example pulley-belt assembly, and last time we calculated the velocity of the belt in that assembly to be 237.99 feet per minute. But before we can go on to calculate the belt’s loose side tension, T2, and tight side tension, T1, we’ll need to discuss unit conversion, specifically how to convert horsepower into foot-pounds per second.

Our working formula for this demonstration is the formula for mechanical power, P, previously introduced and shown again here,

P = (T1 – T2) × V (1)

By engineering convention mechanical power is normally measured in units of foot-pounds per second. But if you’ll recall from a past blog in which we determined the belt’s velocity, V, it was measured in units of feet per minute, not per second.

To further complicate things, the difference in belt tensions, T1 – T2, is stated in units of pounds, and combining these elements together results in P being expressed in foot-pounds per minute, not the required per second, because we are multiplying feet per minute by pounds. That’s a whole lot of unit changing within a single equation, which makes for an awkward situation.

To smooth things out we’ll have to do some converting of units. We’ll start by dividing V by 60 seconds per minute so it can be expressed in units of feet per second,

V = 237.99 feet per minute ÷ 60 seconds per minute (2)

V = 3.93 feet/second (3)

The power in our belt was previously given as 4 horsepower, which must also undergo conversion and be put in terms of foot-pounds per second so it can be used in equation (1).

Unit Conversion, Horsepower to Foot-Pounds per Second

One horsepower is equal to 550 foot-pounds per second, which makes the amount of power, P, in our pulley-belt assembly equal to 2,200 foot-pounds per second.

Units converted, we can now insert the values for V and P into equation (1) to arrive at,

2,200 foot pounds per second = (T1 – T2) × 3.93 feet/second (4)

Next time we’ll use this relationship to develop values for T1 and T2, the belt’s tight and loose side tensions.

Copyright 2017 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: belt, belt and pulley assembly, belt velocity, engineering, foot pounds per second, horsepower, loose side tension, mechanical power, pulley, tight side tension, unit conversions, units

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on Unit Conversion, Horsepower to Foot-Pounds per Second

Monday, August 28th, 2017

|

We’ve been discussing tangential velocity within the context of a pulley and belt assembly in recent blogs, and you may have wondered whether you encounter this phenomenon in your everyday life. Undoubtedly you have. Have you ever driven a long stretch of highway at a fast clip and suddenly come upon a curve in the road posted at a lower speed limit? If you happened not to notice the speed reduction, you may have found yourself slamming on the brakes to regain control of your car. You’ve been caught in a tangential velocity danger zone.

Tangential Velocity Dangers

As this road sign indicates, cyclists must also beware of potentially dangerous circumstances involving tangential velocity. It warns of an upcoming drop in the road, which, depending on their speed, has the potential to catapult them into the air.

Next time we’ll resume our discussion of tangential velocity and other factors within the context of our pulley-belt assembly.

Copyright 2017 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: belt, brakes, danger zone, pulley, pulley and belt assembly, speed, speed limit, tangential velocity

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on Tangential Velocity Dangers

Monday, August 21st, 2017

|

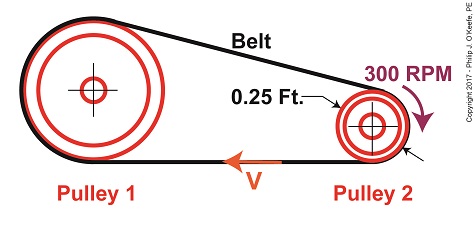

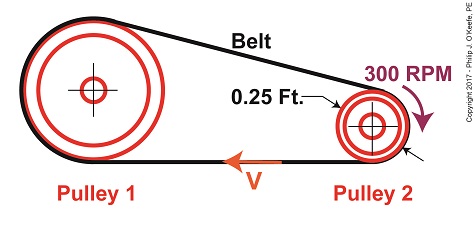

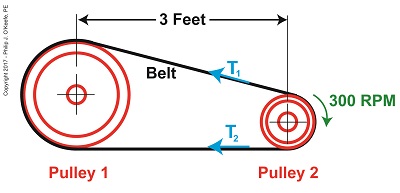

Last time we developed an equation to compute tangential velocity, V, of the belt in our example pulley and belt system. Today we’ll plug numbers into this equation and arrive at a numerical value for this belt velocity.

Belt Velocity

The equation we’ll be working with is,

V = π × D2 ÷ t2 (1)

where, D2 is the diameter of Pulley 2 and π represents the constant 3.1416. We learned that Pulley 2’s period of revolution, t2, is related to its rotational speed, N2, which represents the time it takes for it to make one revolution and is represented by this equation,

N2 = 1 ÷ t2 (2)

We’ll now solve for the belt’s velocity, V, using known values, starting off with rearranging terms so we can solve for t2,

t2 = 1 ÷ N2 (3)

We were previously given that N2 is 300 RPM, or revolutions per minute, so equation (3) becomes,

t2 = 1 ÷ 300 RPM = 0.0033 minutes (4)

This tells us that Pulley 2 takes 0.0033 minutes to make one revolution in our pulley-belt assembly.

Pulley 2’s diameter, D2, was previously determined to be 0.25 feet. Inserting this value equation (1) becomes,

V = π × (0.25 feet) ÷ (0.0033 minutes) (5)

V = 237.99 feet/minute (6)

We’ve now determined that the belt in our pulley-belt assembly zips around at a velocity of 237.99 feet per minute.

Next time we’ll apply this value to equation (6) and determine the belt’s tight side tension, T1.

Copyright 2017 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: belt, belt velocity, loose side tension, minimum belt width, period of revolution, pulley, pulley and belt system, pulley diameter, pulley rotational speed, tangential velocity

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on Belt Velocity

Monday, August 14th, 2017

|

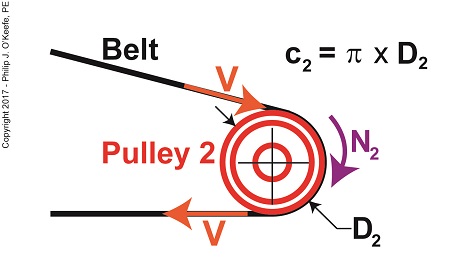

Last time we introduced the Mechanical Power Formula, which is used to compute power in pulley-belt assemblies, and we got as far as introducing the term tangential velocity, V, a key variable within the Formula. Today we’ll devise a new formula to compute this tangential velocity.

Our starting point is the formula introduced last week to compute the amount of power, P, in our pulley-belt example is, again,

P = (T1 – T2) × V (1)

We already know that P is equal to 4 horsepower, we have yet to determine the belt’s tight side tension, T1, and loose side tension, T2, and of course V, the formula for which we’ll develop today.

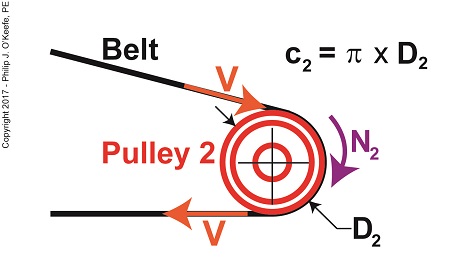

Tangential Velocity

Tangential velocity is dependent on both the circumference, c2, and rotational speed, N2, of Pulley 2. The circumference represents the length of Pulley 2’s curved surface. The belt travels part of this distance as it makes its way from Pulley 2 back to Pulley 1. The rotational speed, N2, represents the rate that it takes for Pulley 2’s curved surface to make one revolution while propelling the belt. This time period is known as the period of revolution, t2, and is related to N2 by this equation,

N2 = 1 ÷ t2 (2)

The rotational speed of Pulley 2 is specified in our example as 300 RPMs, or revolutions per minute, and we’ll denote that speed as N2 in light of the fact it’s referring to speed present at the location of Pulley 2. As we build the formula, we’ll be converting N2 into velocity, specifically tangential velocity, V, which is the velocity at which the belt operates, this in turn will enable us to solve equation (1).

Why speak in terms of tangential velocity rather than plain old ordinary velocity? Because the moving belt’s orientation to the surface of the pulley lies at a tangent in relation to the pulley’s circumference, c2, as shown in the above illustration. Put another way, the belt enters and leaves the curved surface of the pulley in a straight line.

Generally speaking, velocity is distance traveled over a period of time, and tangential velocity is no different. So taking time into account we arrive at this formula,

V = c2 ÷ t2 (3)

Since the surface of Pulley 2 is a circle, its circumference can be computed using a formula developed thousands of years ago by the Greek engineer and mathematician Archimedes. It is,

c2 = π × D2 (4)

where D2 is the diameter of the pulley and π represents the constant 3.1416.

We now arrive at the formula for tangential velocity by combining equations (3) and (4),

V = π × D2 ÷ t2 (5)

Next time we’ll plug numbers into equation (5) and solve for V.

Copyright 2017 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: belt, belt velocity, circumference, engineer, loose side tension, mechanical power formula, period of revolution, pulley, pulleys, speed, tangential velocity, tight side tension, velocity

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on Tangential Velocity

Saturday, July 29th, 2017

|

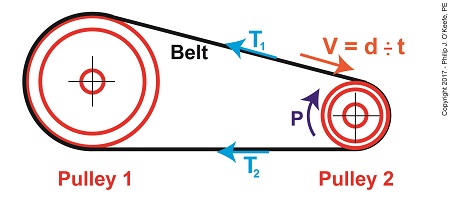

Last time we determined the value for one of the key variables in the Euler-Eytelwein Formula known as the angle of wrap. To do so we worked with the relationship between the two tensions present in our example pulley-belt assembly, T1 and T2. Today we’ll use physics to solve for T2 and arrive at the Mechanical Power Formula, which enables us to compute the amount of power present in our pulley and belt assembly, a common engineering task.

To start things off let’s reintroduce the equation which defines the relationship between our two tensions, the Euler-Eytelwein Formula, with the value for e, Euler’s Number, and its accompanying coefficients, as determined from our last blog,

T1 = 2.38T2 (1)

Before we can calculate T1 we must calculate T2. But before we can do that we need to discuss the concept of power.

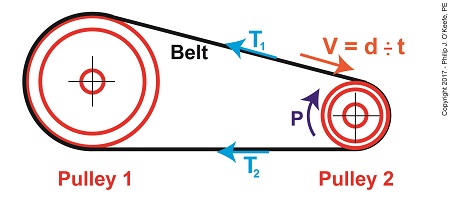

The Mechanical Power Formula in Pulley and Belt Assemblies

Generally speaking, power, P, is equal to work, W, performed per unit of time, t, and can be defined mathematically as,

P = W ÷ t (2)

Now let’s make equation (2) specific to our situation by converting terms into those which apply to a pulley and belt assembly. As we discussed in a past blog, work is equal to force, F, applied over a distance, d. Looking at things that way equation (2) becomes,

P = F × d ÷ t (3)

In equation (3) distance divided by time, or “d ÷ t,” equals velocity, V. Velocity is the distance traveled in a given time period, and this fact is directly applicable to our example, which happens to be measured in units of feet per second. Using these facts equation (3) becomes,

P = F × V (4)

Equation (4) contains variables that will enable us to determine the amount of mechanical power, P, being transmitted in our pulley and belt assembly.

The force, F, is what does the work of transmitting mechanical power from the driving pulley, pulley 2, to the passive driven pulley, pulley1. The belt portion passing through pulley 1 is loose but then tightens as it moves through pulley 2. The force, F, is the difference between the belt’s tight side tension, T1, and loose side tension, T2. Which brings us to our next equation, put in terms of these two tensions,

P = (T1 – T2) × V (5)

Equation (5) is known as the Mechanical Power Formula in pulley and belt assemblies.

The variable V, is the velocity of the belt as it moves across the face of pulley 2, and it’s computed by yet another formula. We’ll pick up with that issue next time.

Copyright 2017 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: belt, distance divided by time, engineering, Euler-Eytelwein Formula, Euler's Number, force, loose side tension, mechanical power, mechanical power formula, power, power transmitted, pulley, tight side tension, velocity, work

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on The Mechanical Power Formula in Pulley and Belt Assemblies

Monday, July 17th, 2017

|

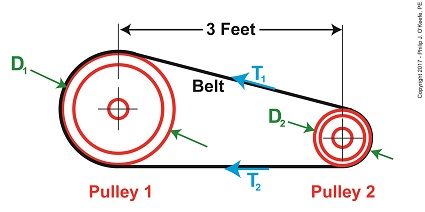

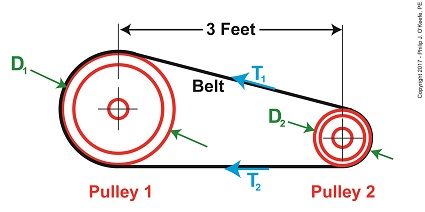

Sometimes things which appear simple turn out to be rather complex. Such is the case with the Euler-Eytelwein Formula, a small formula with a big job. It computes how friction, an omnipresent phenomenon in mechanical assemblies, contributes to the transmission of mechanical power. Today we’ll determine the value of one of the Euler-Eytelwein Formula’s variables, the angle of wrap.

Determining Angle of Wrap

Here again is the basis for our calculations, the Euler-Eytelwein Formula.

T1 = T2 × e(μθ) (1)

To recap what we’ve discussed thus far, T1 is the tight side tension, the maximum the belt can endure before breaking. T2 is the loose side tension. It’s just going along for the ride. The term e is Euler’s Number, a constant equal to 2.718, and the coefficient of friction, μ, for contact points between the belt and pulleys is 0.3 based on their materials.

The formula introduced last time to calculate the angle of wrap, θ, is,

θ = (180 – 2α) × (π ÷ 180) (2)

where,

α = sin-1((D1 – D2) ÷ 2x) (3)

By direct measurement we’ve determined the pulleys’ diameters, D1 and D2, are equal to 1 foot and 0.25 feet respectively. The term x is the distance between the two pulley shafts, 3 feet. The term sin-1 is a trigonometric function known as inverse sine, a button commonly found on scientific calculators.

Inserting our known values into equation (3) we arrive at,

α = sin-1((1.0 foot – 0.25 feet) ÷ 2 × (3 feet)) (4)

α = 7.18 (5)

We can now incorporate equation (5) into equation (2) to solve for θ,

θ = (180 – (2 × 7.18)) × (π ÷ 180) (6)

θ = 2.89 (7)

Inserting the values for m and θ into equation (1) we arrive at,

T1 = T2 × 2.718(0.3 × 2.89) (8)

T1 = 2.38T2 (9)

We have at this point solved for over half of the unknown variables in the Euler-Eytelwein Formula. We still can’t solve for T1, because we don’t know the value of T2. But that will change next time when we introduce yet another formula, this one to determine the amount of mechanical power present in our pulley-belt system.

Copyright 2017 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: angle of wrap, belt, coefficient of friction, Euler-Eytelwein Formula, Euler's Number, friction, loose side tension, mechanical assemblies, mechanical power, pulley, pullies, tight side tension

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on Determining Angle of Wrap

Wednesday, July 5th, 2017

|

Last time we introduced a scenario involving a hydroponics plant powered by a gas engine and multiple pulleys. Connecting the pulleys is a flat leather belt. Today we’ll take a step further towards determining what width that belt needs to be to maximize power transmission efficiency. We’ll begin by revisiting the two T’s of the Euler-Eytelwein Formula and introducing a formula to determine a key variable, angle of wrap.

The Angle of Wrap Formula

We must start by calculating T1, the tight side tension of the belt, which is the maximum tension the belt is subjected to. We can then calculate the width of the belt using the manufacturer’s specified safe working tension of 300 pounds per inch as a guide. But first we’ll need to calculate some key variables in the Euler-Eytelwein Formula, which is presented here again,

T1 = T2× e(μθ) (1)

We determined last time that the coefficient of friction, μ, between the two interfacing materials of the belt and pulley are, respectively, leather and cast iron, which results in a factor of 0.3.

The other factor shown as a exponent of e is the angle of wrap, θ, and is calculated by the formula,

θ = (180 – 2α) × (π ÷ 180) (2)

You’ll note that this formula contains some unique terms of its own, one of which is familiar, namely π, the other, α, which is less familiar. The unnamed variable α is used as shorthand notation in equation (2), to make it shorter and more manageable. It has no particular significance other than the fact that it is equal to,

α = sin-1((D1 – D2) ÷ 2x) (3)

If we didn’t use this shorthand notation for α, equation (2) would be written as,

θ = (180 – 2(sin-1((D1 – D2) ÷ 2x))) × (π ÷ 180) (3a)

That’s a lot of parentheses!

Next week we’ll get into some trigonometry when we discuss the diameters of the pulleys, which will allow us to solve for the angle of wrap.

Copyright 2017 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: angle of wrap, belt, belt tension, coefficient of friction, Euler-Eytelwein Formula, mechanical power transmission, pulley, pulleys

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on The Angle of Wrap Formula

Friday, June 23rd, 2017

|

Belts are important. They make fashion statements, hold things up, keep things together. Today we’re introducing a scenario in which the Euler-Eytelwein Formula will be used to, among other things, determine the ideal width of a belt to be used in a mechanical power transmission system consisting of two pulleys inside a hydroponics plant. The ideal width belt would serve to maximize friction between the belt and pulleys, thus controlling slippage and maximizing belt strength to prevent belt breakage.

An engineer is tasked with designing an irrigation system for a hydroponics plant. Pulley 1 is connected to the shaft of a water pump, while Pulley 2 is connected to the shaft of a small gasoline engine.

What Belt Width does a Hydroponics Plant Need?

Mechanical power is transmitted by the belt from the engine to the pump at a constant rate of 4 horsepower. The belt material is leather, and the two pulleys are made of cast iron. The coefficient of friction, μ, between these two materials is 0.3, according to Marks Standard Handbook for Mechanical Engineers. The belt manufacturer specifies a safe working tension of 300 pounds force per inch width of the belt. This is the maximum tension the belt can safely withstand before breaking.

We’ll use this information to solve for the ideal belt width to be used in our hydroponics application. But first we’re going to have to re-visit the two T’s of the Euler-Eytelwein Formula. We’ll do that next time.

Copyright 2017 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: belt, belt breakage, coefficient of friction, engine, engineer, horsepower, leather belt, mechanical power transmission, pulley, pump

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on What Belt Width does a Hydroponics Plant Need?

Tuesday, June 13th, 2017

|

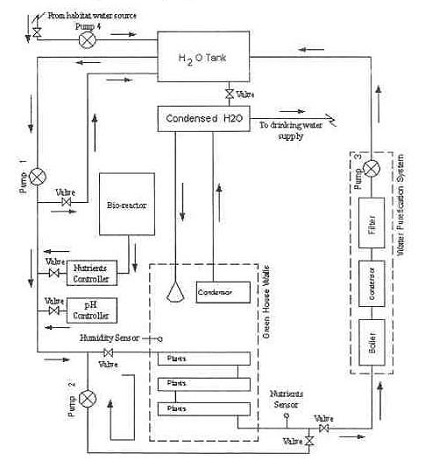

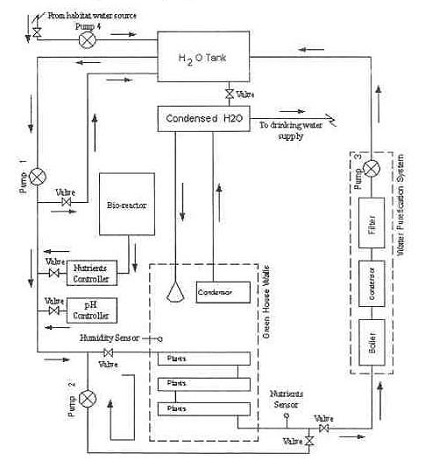

Last week we saw how friction coefficients as used in the Euler-Eyelewein Formula, can be highly specific to a specialized application, U.S. Navy ship capstans. In fact, many diverse industries benefit from aspects of the Euler-Eytelwein Formula. Today we’ll introduce another engineering application of the Formula, exploring its use within the irrigation system of a hydroponics plant.

Another Specialized Application of the Euler-Eyelewein Formula

Pumps conveying water are an indispensable part of a hydroponics plant. In the schematic shown here they are portrayed by the symbol ⊗.

In our simplified scenario to be presented next week, these pumps are powered by a mechanical power transmission system, each consisting of two pulleys and a belt. One pulley is connected to a water pump, the other pulley to a gasoline engine. A belts runs between the pulleys to deliver mechanical power from the engine to the pump.

The width of the belts is a key component in an efficiently running hydroponics plant. We’ll see how and why that’s so next time.

Copyright 2017 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: belt, belt width, coefficient of friction, engineering, Euler-Etytelwein Formula, gasoline engine, hydroponics, mechanical power transmission, power, pulley, pump

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability, Professional Malpractice | Comments Off on Another Specialized Application of the Euler-Eyelewein Formula

Sunday, June 4th, 2017

|

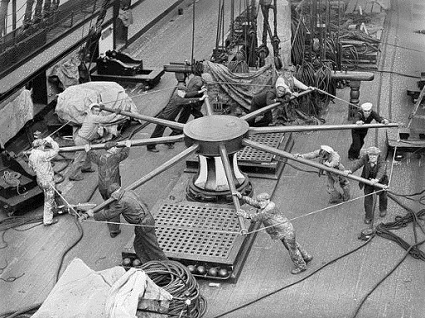

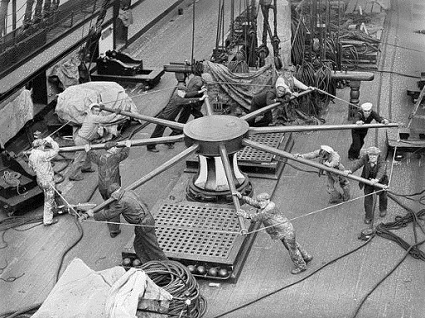

We’ve been talking about pulleys for awhile now, and last week we introduced the term friction coefficient, numerical values derived during testing which quantify the amount of friction present when different materials interact. Friction coefficients for common materials are routinely presented in engineering texts like Marks’ Standard Handbook for Mechanical Engineers. But there are circumstances when more specificity is required, such as when the U.S. Navy, more specifically the Navy Material Command, tested the interaction between various synthetic ropes and ship capstans and developed their own specialized friction coefficients in the process.

Navy Capstans and the Development of Specialized Friction Coefficients

Capstans are similar to pulleys but have one key difference, they’re made so rope can be wound around them multiple times. When the Navy set out to determine which synthetic rope worked best with their capstans, they did testing and developed highly specialized friction coefficients in the process. This research was at one time Top Secret but has now been declassified. To read more about it, follow this link to the actual handbook:

https://archive.org/stream/DTIC_ADA036718#page/n0/mode/2up

Copyright 2017 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: capstan, engineering, friction, friction coefficient, pulley, rope

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability | Comments Off on Navy Capstans and the Development of Specialized Friction Coefficients