| When I had the misfortune of getting stuck in my Uncle Jake’s outhouse as a kid, I would allow my hysteria to get the best of me and forget my uncle’s instructions on how to get out. It was a series of raps and a single kick that would prove to be the magic formula, and once I had calmed myself down enough to employ them I would succeed in working the door’s rusty latch open. Our relay circuit below has a much less challenging system to effectively unlatch the pattern of electric current.

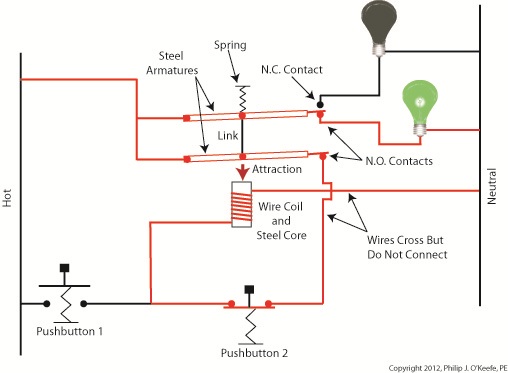

Figure 1 shows our latched circuit, where red lines denote the flow of current. Figure 1

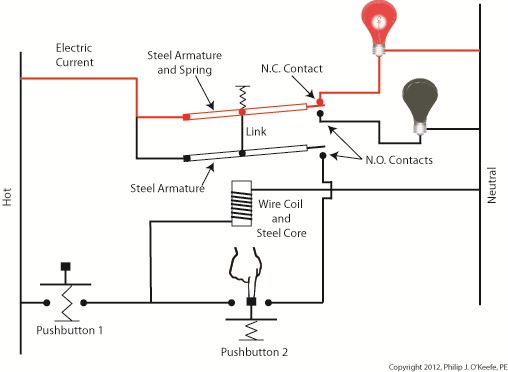

If you recall, the relay in this circuit was latched by pressing Pushbutton 1. When in the latched state, the magnetic attraction maintained by the wire coil and steel core won’t allow the relay armatures to release from their N.O. contacts. The relay’s wire coil stays energized via Button 2, the red bulb goes dark while the green bulb remains lit, even though Button 1 is no longer actively depressed. Now let’s take a look at Figure 2 to see how to get the circuit back to its unlatched state. Figure 2

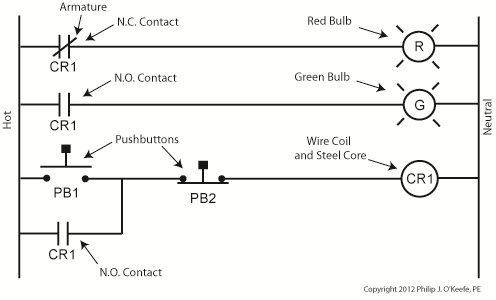

With Button 2 depressed the flow of current is interrupted and the relay’s wire coil becomes de-energized. In this state the coil and steel core are no longer magnetized, causing them to release their grip on the steel armatures. The spring will now pull them back until one of them makes contact with the N.C. contact. The red bulb lights again, although Button 2 is not being actively depressed. At this point the electric relay has become unlatched. It can be re-latched by depressing Button 1 again. Let’s see how we can simplify Figure 2’s representation with a ladder diagram, as shown in Figure 3. Figure 3

We’ve seen how this latching circuit activates and deactivates bulbs. Next time we’ll see how it controls an electric motor and conveyor belt inside a factory. ____________________________________________ |

Posts Tagged ‘button’

Industrial Control Basics – Unlatching the Latching Circuit

Sunday, February 5th, 2012Tags: armature, bulbs, button, electric relay, electrical engineering, engineering expert witness, forensic engineer, hot neutral, industrial control, ladder diagram, latched relay, magnetism, mechanical relay, N.C. contact, N.O. contact, normally closed contact, normally open contact, pushbutton, pushbutton control, relay ladder logic, spring, unlatching a relay, wire, wire coil

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability, Professional Malpractice | Comments Off on Industrial Control Basics – Unlatching the Latching Circuit

Industrial Control Basics

Sunday, December 4th, 2011| When I was a child in school I loved field trips. They didn’t happen too often, but when they did they were a welcomed break from the routine of the classroom. Once we went on a tour of a large factory that made telephones. During the tour we walked amongst gargantuan machines, conveyor belts, furnaces, boilers, pumps, and compressors, all energized and working together to transform raw materials into telephones. Sequences of manufacturing and assembly operations, from the simple to the most complex, were carefully orchestrated with no apparent human intervention.

The equipment in the telephone factory was certainly impressive to watch, and our tour guides did a fine job of explaining what was happening, except for one important detail. I realized after we left that no one had explained who or what was actually controlling the machinery. I realized even then that machines can’t think for themselves. They can only do what humans tell them to do. I didn’t know it at the time, but the telephone factory setup included some interesting examples of industrial control systems. Industrial control systems can be broken down into two basic categories, manual controls and automatic controls. Manual controls work as their name implies, that is, someone must manually press a button or throw a switch to initiate factory operations. This involves continual monitoring of processes, coupled with hands-on activities to keep everything working. Automatic controls still require human intervention to some extent, such as initiating operations, but once that’s done they move into self-regulation mode until the operations are shut down at the end of production. Employees are thus freed up to spend time doing things which are not automated. Automatic controls are excellent at handling mundane, repetitive tasks that humans tend to get quickly bored with. Boredom leads to a lack of attention, and this may lead to accidents, so utilizing automatic controls often makes for a safer work environment. Next time we’ll begin our examination of how manual and automatic controls work within the context of an industrial setting. To begin, we’re going to take a virtual field trip back to the telephone factory and look at some basic industrial control examples. ____________________________________________

|

Tags: accidents, automatic control, boilers, button, compressors, controlling machinery, conveyor belt, engineering expert witness, factory, forensic engineer, furnaces, industrial control, machine control, machines, manual control, process monitoring, pumps, switch, telephones

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability, Professional Malpractice | Comments Off on Industrial Control Basics