| Ever overdraw on your checking account or max out a credit card? It’s not hard to do if you’re not keeping track of things. How can we manage household expenses without some sort of record keeping?

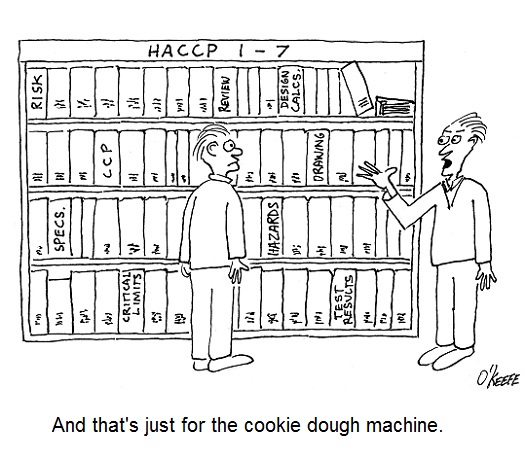

Away from home, in the business sector, record keeping becomes even more important. In fact, it’s the very thing covered by HACCP Design Principle No. 7. Principle 7: Establish record keeping procedures. – This HACCP principle requires that all food manufacturing plants maintain records to show they implemented a HACCP plan, are following all principles, and the plan is working effectively. Let’s look at an example. In keeping with the directive of HACCP Design Principle 7, the engineering department of a food manufacturing plant must keep records for each design project. The design record for a new cookie forming machine would contain things like engineering calculations to determine strength requirements of machine parts and supports, as well as power requirements for the electric motor that drives the machine. This design record would also contain documentation concerning materials selected to construct the machine, as well as dimensioned mechanical drawings of the machine and its parts. These dimensioned drawings will show all physical dimensions of the machine and its constituent parts. The record would also contain test results and analysis of the results. Lastly, the design record must include a risk analysis of potential hazards that could result. Other activities include identification of CCPs, establishment of critical limits, and other factors in accordance with HACCP Design Principles 1 through 5. In other words, the record must be complete, bearing witness to an effective adherence to HACCP Design Principles 1 through 5. Principle 7 also encompasses guidelines set in place through Design Principle 6, which calls for the establishment of procedures to govern Principles 1 through 5. A complete record would contain the procedures themselves, along with any revisions. It would also contain documentation that the procedures were reviewed and approved by management along the way. Finally, of what use would records be if they were incomplete, disorganized, and outdated? A document control system not only establishes procedures, but assigns responsibilities to personnel within the department for filing design records to make sure that everything is up to snuff. This system would encompass everything, from the creation of engineering documents, to their timely entry into the record keeping system. We have now exhausted our discussion on HACCP Design Principles. We’ll switch to a new topic next time, examining some basic concepts behind the control of industrial equipment and machinery. ____________________________________________

|

Posts Tagged ‘design record’

Food Manufacturing Challenges – HACCP Design Principle No. 7

Sunday, November 27th, 2011Tags: calculations, CCP, cookie machine, critical control point, critical limits, design record, dimensioned drawings, electric motor, engineering calculations, engineering documents, engineering expert witness, food contamination, food factory, food manufacturing equipment design, food processing equipment, food production line, forensic engineer, HACCP, HACCP design principle, HACCP plan, hazard analysis, Hazard Analysis and Critical Control Point, machine parts, procedures, record keeping, risk analysis, test result

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability, Professional Malpractice | Comments Off on Food Manufacturing Challenges – HACCP Design Principle No. 7