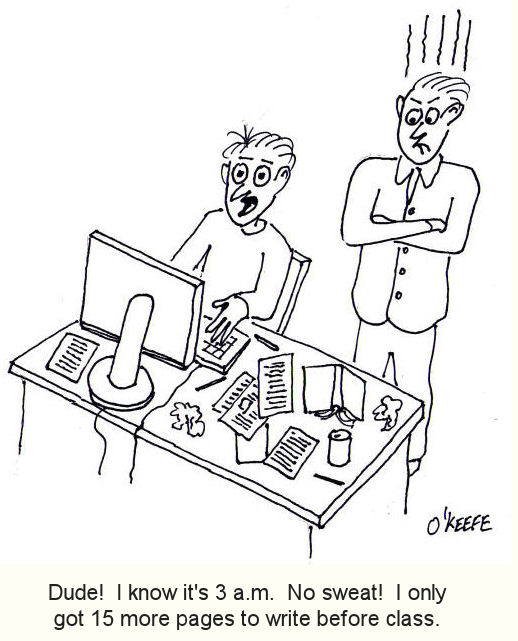

| Did you ever hear the saying, “garbage in, garbage out?” Perhaps you’ve used it yourself at times, as when your teenager insists on writing their 20-page term paper the night before it’s due. Parents, having the benefit of decades of life experience, know that the outcome of a last ditch effort of this type will most likely not turn out well.

This wisdom also applies particularly well to the medical manufacturing process. The FDA is like the parent in this instance, mandating that Design Transfer Procedures be in place to avert the types of disasters which might ensue if the “garbage” philosophy were carried out. Meant to ensure that medical device designs are correctly translated into production specifications for manufacturing, Design Transfer Procedures keep those directly involved with the manufacturing process in check. It is absolutely vital that those involved in manufacturing receive accurate and complete information. Imagine what would happen if an engineer provided a manufacturer with faulty design information. Components could be made to the wrong specifications or of a material that proves toxic to the application. These errors range in negative effect from being costly in terms of dollars wasted to perhaps costing someone their life. A Design Transfer Procedure would ensure that a variety of mishaps do not occur during the transfer process. The procedure is typically overseen by the medical device company’s management. For example, a Design Transfer Procedure would lay out responsibilities of supervisors and managers to make sure the latest revision of electrical schematics, bills of materials, Gerber files, and quality testing procedures are received by the manufacturer of a device’s printed circuit boards. It’s important that the order is received in a timely manner so as not to hold up the manufacturing process. However, it’s much more important that the printed circuit board is made properly, the correct electrical components are placed on it in the correct orientation, and it is tested to make sure it doesn’t malfunction after assembly. Design Change Procedures basically ensure that when changes are necessary, the medical device company follows all the procedures for Design and Development Planning, Design Input, Design Output, Design Review, Design Verification, and Design Validation. Once the changes are reviewed, validated, verified, and approved, they can be incorporated into the original device design. This is where the Design Change Procedure must dovetail with the Design Transfer Procedure to make sure the correct information is provided to the company’s management staff in the procurement, manufacturing, product service, and warehouse departments. This is to make sure they can keep component vendors on track with the changes, maintain sufficient inventory of the changed components, put the right components in the device during assembly, and properly support repair technicians in the field. Yet another aspect of Design Controls promulgated by the FDA comes into play with the establishment of procedures for maintaining a Design History File (DHF). This DHF contains all documentation created during the life cycle of the project, meaning, movement from creation to completion and on into market introduction, sometimes beyond. DHF Procedure sets up protocols for collection and organization of information about the medical device design, starting with design documentation and covering the gamut from design changes, to validation testing, to design verification, and on to design review. All this is done to ensure that the initial product design was developed in accordance with the original design plan and overall product design requirements. _____________________________________________ |

Posts Tagged ‘design transfer’

Medical Device Design Controls – Transfer, Changes, and History

Sunday, September 12th, 2010Medical Device Design Controls – Output, Verification, Review, and Validation

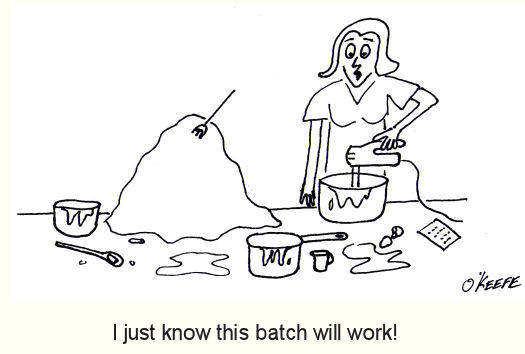

Sunday, September 5th, 2010| Recently my wife was on a quest to make the perfect pound cake, but before she put butter to flour she did her research. What’s the best butter? Best flour? Eventually she came up with a recipe she felt would prove to be the Queen of all pound cakes. After the recipe came reviews by her test panel, or family members, including myself. Questions were asked, such as, When you first bite into a pound cake, do you want to be aware of vanilla or lemon? It was only then that she would begin to combine ingredients for the final mouth watering product. Very much this same procedure is used when coming up with a new medical device.

Previously we’ve discussed FDA requirements for medical devices as they concern design controls with respect to design and development planning and design input procedures. We’ll now focus on requirements for Design Output, Design Verification, and Design Review Procedures. Design Output and Design Verification Procedures go hand in hand to ensure that design output is properly documented, organized, reviewed, and evaluated in light of design input. What this means is that medical device companies must scrutinize and evaluate what is going into the design process, then make a comparison to what is coming out. The design is ultimately verified when all requirements for the medical device as previously set out have been met. “Design output” is just another name for work product after major phases of the design project are completed, such as when my wife determined which butter would produce the best pound cake. Design output typically takes the form of specifications, notes, calculations, computer programs, mechanical drawings, electrical schematics, printed circuit board (PCB) layouts, bills of materials (BOM), mockups, prototypes, test data, and test reports. These are then utilized by people outside engineering circles to manufacture components and assemble them into a final product. Design Review Procedures ensure that the design output is evaluated by others not directly involved in or responsible for the design work product, much as when family members served as a reviewing committee for my wife’s inquiries into taste preferences in pound cake. Sometimes she’d even ask a friend or neighbor to put their two cents in, and companies, too, will at times go outside and hire consultants to perform this function. By so doing, unbiased opinions are sought out, in the hopes that this fresh set of eyes will be more likely to spot errors, omissions, and misinterpretations that could prove disastrous if put into play. Design reviews are typically conducted after each major phase of a design project is complete. Just as a recipe that looks good on paper may not necessarily taste good, a device design will often seem to work perfectly on paper, then prove otherwise when its manufacture begins or it’s used in the field. Ideally bugs are worked out before the product hits production and, later, the marketplace. Design Validation Procedures make use of prototypes for testing and careful evaluation under simulated or actual use conditions. Does the design safely meet requirements for intended use? Does it conform with industry standards? If not, there’ll be a lot of wasted “dough” going into the trash — pun intended! Next time we’ll explore FDA requirements for Design Transfer and Design Changes. We’ll also talk about procedures for Design History Files. _____________________________________________ |