| Picture yourself on a highway, it’s dark out, the wind is blowing fiercely, and you’re unable to see that the pavement is accumulating icy patches. You hit one, and your car veers out of control. Luckily you drive one of the new generation of “smart” vehicles. Wheel sensors detect your predicament and immediately initiate a sequence of events to correct the situation and bring your vehicle back into control.

Corrective measures need to be taken in many situations when things go awry, whether they be computer-generated or human-generated corrections, and food manufacturing facilities are not exempt from the process. Let’s look at how this applies within HACCP Design Principle No. 5. Principle 5: Establish corrective actions. – Simply put, when an established critical limit at a designated critical control point (CCP) has been found not to be functioning as intended, thereby exposing consumers to potential food safety issues, design engineers must enact corrective measures to resolve the issue as soon as possible. Let’s return to the example set out in our last article, where we discussed HACCP Design Principle 4. An engineering manager has discovered a problem with the lower critical limits established by her design engineer’s software logic as it concerns a CCP established with regard to cooker temperature. The time and temperature in the logic create a hazardous situation by not taking into account that larger cuts of meat require more cooking time, resulting in them being undercooked. Fortunately, the engineering manager’s diligent and ongoing day-to-day monitoring has alerted her to the error. She immediately provides feedback about it to the design engineer, who makes corrections to the software logic. Problem solved, and all is working well within the food manufacturing plant, right? Yes, but we’re not finished. We have to make sure that a mechanism is set in place to ensure that HACCP Principles 1 through 5 are being followed and that they are actually working to protect consumers from potential food contamination hazards. Next time we’ll take a look at the last of the HACCP Design Principles, No. 6, which concerns itself with maintenance and housekeeping issues. ____________________________________________ |

Posts Tagged ‘food manufacturer’

Food Manufacturing Challenges – HACCP Design Principle No. 5

Saturday, November 12th, 2011Food Manufacturing Challenges – Cleanliness

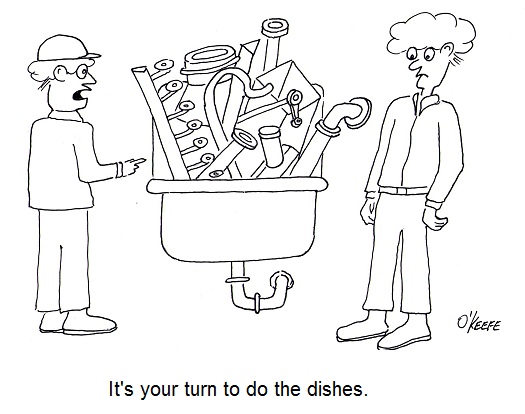

Monday, October 3rd, 2011| My wife and I have an agreement concerning the kitchen. She cooks, I clean. Plates and utensils are easy enough to deal with, especially when you have a dishwasher. Pots and pans are a little more challenging. But what I hate the most are the food processors, mixers, blenders, slicers and dicers. They’re designed to make food preparation easier and less time consuming, but they sure don’t make the clean up any easier! Quite frankly, I suspect the time involved to clean them exceeds the time saved in food preparation.

Food processors on a larger scale are also used to manufacture many food products in manufacturing facilities, and being larger and more complicated overall, they’re even more difficult to clean. For example, I once designed a production line incorporating a dough mixer for one of the largest wholesale bakery product suppliers in the United States. A small elevator was required to lift vast amounts of ingredients into a mixing bowl the size of a compact car. Its mixing arms were so heavy, two people were required to lift them into position. It was also my task to ensure that the equipment as designed was capable of being thoroughly cleaned in a timely and cost effective manner. Food processing machinery must be designed so that all areas coming into contact with ingredients can be readily accessed for cleaning. And since most of the equipment you are dealing with in this setting is far too cumbersome to be portable, the majority of the cleaning must be cleaned in place, known in the industry as CIP. To facilitate CIP, commercial machinery is designed with hatches and special covers that allow workers to get inside with their cleaning equipment. Small, portable parts of the machine, such as pipes, cutting blades, forming mechanisms, and extrusion dies, are often made to be removable so that they can be carried over to an industrial sized sink for cleaning out of place, or COP. These potable machine components are typically removable for COP without the use of any tools and are fitted with flip latches, spring clips, and thumb screws to facilitate the process. Everything in a food manufacturing facility, from production machinery to conveyor belts, is typically cleaned with hot, pressurized water. The water is ejected from the nozzle end of a hose hooked up to a specially designed valve that mixes steam and cold water. The result is scalding hot pressurized water that easily dislodges food residues. Bacteria doesn’t stand a chance against this barrage. The water, which is maintained at about 180°F, quickly sterilizes everything it makes contact with. It also provides a chemical-free clean that won’t leave behind residues. Once dislodged, debris is flushed out through strategically placed openings in the machine which then empty into nearby floor drains. As a consequence of the frequent cleanings commercial food preparation machinery requires, their parts must be able to withstand frequent exposure to high pressure water streams. Parts are typically constructed of ultra high molecular weight (UHMW) food-grade plastics and metal alloys such as stainless steels, capable of withstanding the corrosive effects of water. And since water and electricity make a dangerous combination, gaskets and seals on the equipment must be tight enough to protect against water making its way into motors and other electrical parts. Next time we’ll look at how design engineers of food manufacturing equipment use a systematic approach to minimize the possibility of food safety hazards, such as product contamination. ____________________________________________ |