|

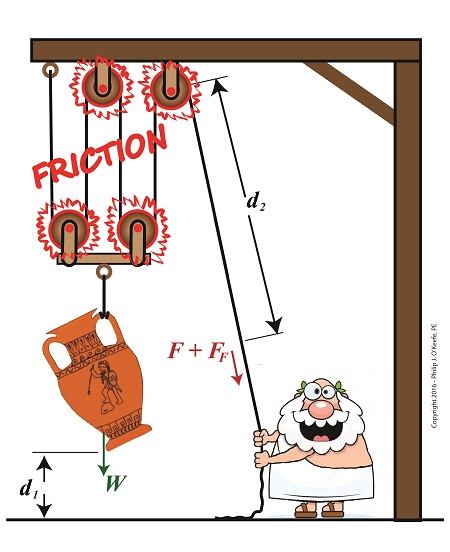

Last time we began work on a numerical demonstration and engineering analysis of the inequality of work input and output as experienced by our example persona, an ancient Greek lifting an urn. Today we’ll get two steps closer to demonstrating this reality as we work a compound pulley’s numerical puzzle, shuffling equations like a Rubik’s Cube to arrive at values for two variables crucial to our analysis, d2, the length of rope he extracts from the pulley while lifting, and F, the force/effort required to lift the urn in an idealized situation where no friction exists. A Compound Pulley’s Numerical Puzzle is Like a Rubik’s Cube

We’ll continue manipulating the work input equation, WI, as shown in Equation (1), along with derivative equations, breaking it down into parts, and handle the two terms within parentheses separately. Term one, (F × d2), corresponds to the force/effort/work required to lift the urn in an idealized no-friction world. It’ll be our focus today as it provides a springboard to solving for variables F and d2. WI = (F × d2) + (FF × d2) (1) Previously we learned that when friction is present, work output, WO, is equal to work input minus the work required to oppose friction while lifting. Mathematically that’s represented by, WO = WI – (FF × d2) (2) We also previously calculated WO to equal 80 Ft-Lbs. To get F and d2 into a relationship with terms we already know the value for, namely WO, we substitute Equation (1) into Equation (2) and arrive at, 80 Ft-Lbs = (F × d2) + (FF × d2) – (FF × d2) (3) simplified this becomes, 80 Ft-Lbs = F × d2 (4) To find the value of d2, we’ll return to a past equation concerning compound pulleys derived within the context of mechanical advantage, MA. That is, d2 ÷ d1 = MA (5) And because in our example four ropes are used to support the weight of the urn, we know that MA equals 4. We also know from last time that d1 equals 2 feet. Plugging these numbers into Equation (5) we arrive at a value for d2, d2 ÷ 2 ft = 4 (6) d2 = 4 × 2 ft (7) d2 = 8 ft (8) Substituting Equation (8) into Equation (4), we solve for F, 80 Ft-Lbs = F × 8 ft (9) F = 10 Pounds (10) Now that we know F and d2 we can solve for FF, the amount of extra effort required by man or machine to overcome friction in a compound pulley assembly. It’s the final piece in the numerical puzzle which will then allow us to compare work input to output. Copyright 2017 – Philip J. O’Keefe, PE Engineering Expert Witness Blog ____________________________________ |