|

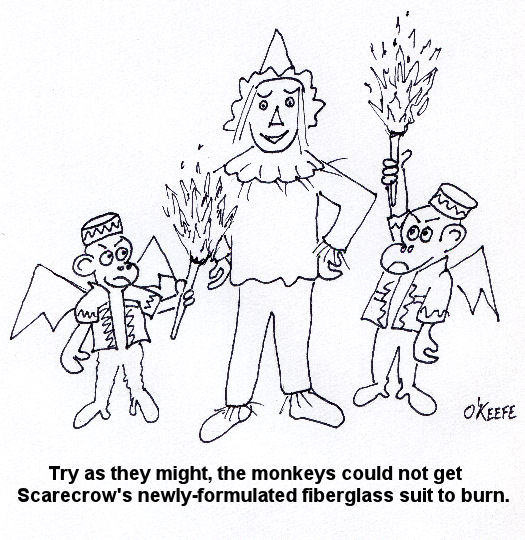

Metals, polymers, ceramics, and composites… Oh, my! Imagine Dorothy, lost in a forest of these materials while on her way to Oz. The Scarecrow is most probably a composite being. And the Tin Man is most definitely made of metal. But that Cowardly Lion sure poses a quandary for Dorothy. Is this beast polymer, ceramic, or something else? She soon learns that he’s comprised of organic materials, and that’s in a whole different forest. What’s he doing here, anyway? The Tin Man was strong enough to cut down trees, until he got rained on. As you’ve probably noticed, metallic materials such as steel are the most frequently used to make machine and structural components, and this is primarily due to their strength and durability. As a result of the frequency of their usage, the formation of metal materials and their resulting properties are the primary focus of material science study for mechanical engineers. To prevent our Tin Man from rusting after the rain, he should have been formulated with particular properties which provide not only strength but corrosion resistance. The main ingredient in the recipe for his fancy silver garb would then be iron. You would add carbon and other elements in specific proportions to the iron under carefully controlled heating conditions in a blast furnace. You would then cool the molten steel down at a controlled rate and subject it to mechanical forces after it is solidified. Voila! The material is ready to be cut and shaped into components, and our Tin Man would be all set, prepared to withstand the onslaught of any weather. The study of the formation and properties of polymers and ceramics is also an important part of materials science study. Polymers, often used to make plastics, consist of large molecules which comprise non-metallic elements like carbon, hydrogen, and oxygen. Now those are materials that organic beings are also made of. Could it be that our Cowardly Lion was a polymer? Ceramics are hard and brittle materials consisting of both metallic and nonmetallic elements. There are many examples of ceramic materials ranging from cements to cutting bits for machine tools. Cowardly Lion could not possibly be made of these; he is anything but hard and brittle. Then there is a whole world of very unique things, like our Scarecrow, that are made of composite materials. Sure, he’s made of straw, and he’d be the first one to admit to that, but what about that dashing outfit of his? Composite materials consist of two or more materials combined to make a material with properties distinctly different from the original constituent materials by themselves. An example composite material that might have worked better for Scarecrow is fiberglass, where glass fibers are mixed with polymer resins. Glass by itself is brittle and easily broken, but when it is formed into thin fibers and combined with polymer resin, then allowed to harden and cure, the composite material becomes strong and durable. The fiberglass can then be easily shaped into forms to make automobile bodies, boat hulls… and scarecrow parts? At least it’s not highly flammable, like Scarecrow’s straw. Other examples of composites include steel reinforced concrete, Kevlar, plywood, safety glass, and carbon reinforced plastic. Most of these would have worked better for our Scarecrow than what he was originally endowed with. Well, that’s materials science in a nutshell. We’ll discuss thermodynamics next time, which is the study of the properties of steam and other media used to absorb and transfer heat energy in power plants, engines, and refrigeration systems. Hmm, I wonder if the Wicked Witch had the inside track on this stuff? _________________________________________________________________ |

Posts Tagged ‘materials science’

Materials Science In Mechanical Engineering, Part I

Sunday, November 22nd, 2009|

Imagine a chef without a fry pan, a mixer, or attempting to create a recipe without any idea of how the ingredients will combine. Is the end result likely to be something you’d want to eat? Something with just the right visual appeal, aroma, taste, and texture? Unlikely. Likewise, what good would a mechanical design be if an engineer had no idea of what kind of materials to use? The results would be haphazard, and this could lead to problems more serious than lack of palatability. We’re talking serious consequences here, such as product failure, injury, or death. In the mechanical engineering arena, just as in the cooking arena, materials used possess certain properties which render them useful for specific purposes. Just as a chef has her pantry, an engineer has a wide variety of materials available to her to choose from, and new materials are developed all the time. The vastness of the materials available to an engineer makes it difficult for all of them and their properties to be committed to memory. What is possible, however, is to develop a firm understanding of the underlying principles that govern their properties. It is this general understanding of materials’ properties that enables engineers to select between materials. There are key questions to be answered in the search for the ideal materials to do a job. Which materials would be the most economical? Which would give optimal performance? The best durability? Materials science provides an understanding of the relationship between the structure of materials at an atomic or molecular level and their macroscopic properties. In other words, the engineer learns how atoms are arranged and bonded together at a microscopic level, which in turn form the material perceived by the naked eye. The ultimate arrangement of molecules is based upon how the virgin material was processed into its final form. By “processed,” I mean the application of heat, cooling, mechanical forces, etc. Knowing the composition of a material and how it was processed allows engineers to predict how the material will react to things like stress, strain, heat, corrosives, radiation, and electrical currents. It’s a big world out there, and it’s filled with materials to explore. Next week we’ll begin that exploration. _________________________________________________________________ |