| Last time we began our look at the Production stage of systems engineering. We learned that cost reduction is a frequent component of this stage due to market fluctuations and ongoing stakeholder requirements to cut costs, and that savings can be made through substitution of plastic for metal parts. In fact, there are many faces to cost reduction. We’ll explore another of those today.

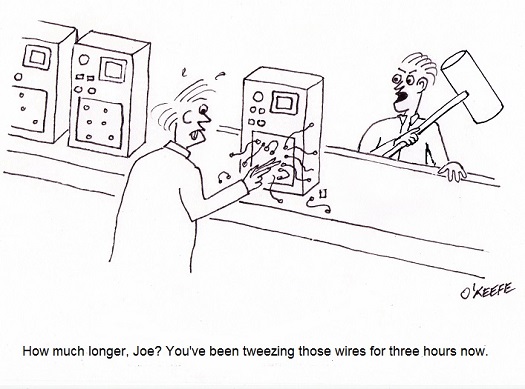

Cost reduction isn’t limited to material expense. Within the manufacturing process itself there are often ample opportunities for cost reduction. As an example let’s say we’re manufacturing a medical device known as a percussion therapy device on an assembly line employing 21 workers over three shifts. This line assembles 300 devices per day at a combined material and labor cost of $2,100 per unit. Percussion therapy devices are frequently used within the medical setting as they perform the very important function of helping to dislodge mucous from patients’ lungs. As such, they are in high demand and the market for them competitive. In our scenario some stakeholders in the device’s manufacture, in this case sales and marketing managers, specify that a cost reduction of $200 per device is necessary to avoid losing ground to competitors. In response to this directive, design engineers take a fresh look at the assembly process. They identified several bottlenecks at key junctures during which manual labor is involved. They note that due to the painstaking work required at these stages, production is slowed. Assembly lines operate dynamically, meaning any disturbance in the flow of activities has vast repercussions down the line. Bottlenecks in flow slow production lines, just as they do traffic on key arteries. A tie-up on assembly lines equates to production delays, and these may lead to difficulty in filling customer orders. Impatient customers have been known to turn to competitors when their orders aren’t filled, and this translates to lost revenue to our manufacturer. Next week we’ll see what manufacturing changes are employed to solve identified problems, and we’ll see how man’s best friend is not a dog, but a robot. ___________________________________________ |

Posts Tagged ‘plastic parts’

Systems Engineering In Medical Device Design – Production, Part 2

Sunday, March 3rd, 2013Tags: assembly line, cost reduction, engineering expert witness, forensic engineer, manufacturing process, medical device design, metal parts, percussion therapy, plastic parts, Production Stage, stakeholder requirements, systems engineering

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability, Professional Malpractice | Comments Off on Systems Engineering In Medical Device Design – Production, Part 2