| Several years ago I was asked by power producers within the electric utility industry to write and then present a training course on the subject of coal power plant fundamentals. The finished product was a two day introductory course on the energy transformation process within a coal fired plant.

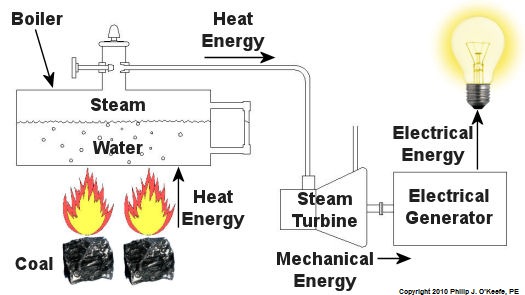

Since that time my seminar, entitled Coal Power Plant Fundamentals, has been presented to a variety of audiences, including Mirant Corporation, Platte River Power Authority, and Integrys Energy Group, Inc. Audience makeup has been diverse and has included equipment manufacturers, mining companies, power industry consultants, and regulatory agencies. This seminar, which I continue to present today in meeting rooms across the country, covers all major systems in a typical power plant, from coal handling when the coal first enters the plant, to its eventual end destination, the electrical switch yard which facilitates power transmission to customers. My Power Point presentation is embellished with ample illustrations, including photographs that I have taken during the course of my career and diagrams which I created using CAD, or Computer Aided Drawing software, one of which is featured below. In addition to the overhead slides, I provide a 150-page bound book which is distributed to seminar attendees. They use it to both follow along with my lecture and have a source of refresher material to take home with them. I’ve been told that having my illustrations in front of them makes a world of difference towards their understanding of the subject matter. The unique thing about my course is that it focuses on the simplified presentation of complex engineering concepts, much like my blogs do. Of course it always helps to have an engineering background or scientific background of sorts, but I wrote the course to accommodate understanding of the subject matter by individuals without any technical background. Accountants, salespersons, administrative staff, plant operating and maintenance workers, and journalists have all found the course to be easy to follow, interesting, and informative. So how do you get electricity from coal? To answer this question and give you a sampling of my seminar material let’s take a look at Figure 1. Figure 1 – The Coal Power Plant Energy Transformation Process Following along from left to right, the coal is first burned in order to transform the chemical energy which it contains into heat energy. That heat energy is then absorbed by water inside a nearby boiler, where it is converted into steam. The heat energy in the steam flows through a pipe into a steam turbine where it is again transformed, this time into mechanical energy that enables the turbine shaft to spin. The mechanical energy in the turbine is then transmitted by its shaft, enabling it to turn an electrical generator. And, finally, the mechanical energy is transformed by the generator into electrical energy for our usage. Simple process, right? Well, maybe, maybe not. My illustration certainly helped to simplify things, but there are a lot of details that were purposely omitted so as not to “muddy the waters.” It’s those details which have the potential to make things a lot more complicated, and next week we’ll begin to take a closer look at some of them. _____________________________________________ |

Posts Tagged ‘power plant training’

Coal Power Plant Fundamentals

Sunday, January 23rd, 2011Coal Fired Boiler Explosions

Sunday, July 25th, 2010|

Try this for a tongue-twister: Coal fired electric utility power plant boiler… If you’ve been reading along with us for the last couple of weeks, you now have a pretty good idea of what these are and what they do. These boilers are contained within furnaces in coal fired power plants. The furnace’s job is to combine coal and air to create a combustion process. It is like a big, insulated enclosure that keeps the heat energy from the combustion process from escaping before it can be absorbed by the water and steam in the boiler tubes. The heat energy is then funneled to the steam turbine to spin an electrical generator, creating the energy which will eventually find its way into our homes and businesses. During the operation of the boiler, coal and air must be introduced into the furnace at carefully measured rates to maintain a proper fuel-to-air ratio which will enable the release of heat energy from the coal at a safe, controlled rate. Fuel-air ratio is the amount of coal entering the furnace divided by the amount of air entering the furnace. If this ratio isn’t precisely maintained, conditions may be right for an explosion to occur. Specifically, the ratio has to fall within an “explosive range.” Once within this range, all that is needed is an ignition source, such as hot ash, or even mere static electricity, and the result may be a furnace explosion. There are certain times at which furnace explosions are more likely to occur than others, such as when the boiler is being started, operated at less than full capacity, or shut down. When a furnace explodes, a pressure wave moves out from the center of the blast. This pressure wave will bear up against the sides of the furnace with great force, and if the pressure is high enough the sides of the furnace, which are made of heavy steel components, will actually bend and split open. Boiler tubes may even rupture, releasing high pressure steam and water into the power plant and furnace. At the very least, the boiler will be down for expensive repairs and no electricity can be produced by its turbine generator. This down time can last for many months and results in lost revenue to the energy producer. Aside from an explosive fuel-to-air ratio, there are other potential causes of furnace explosions. For example, poor coal quality can lead to incomplete combustion, or the flame going out completely, encouraging unburned coal particles to settle and accumulate in the furnace. The accumulation of coal can grow to the point where it forms an explosive mixture when combined with the right amount of air. So how can boiler explosions be prevented? The National Fire Protection Association (NFPA) looked into the problem and developed an industry standard. This standard is known as NFPA 85, Boiler and Combustion Systems Hazards Code. Its purpose is to contribute to operating safety and prevent uncontrolled fires, explosions, and implosions of coal fired boilers. NFPA 85 lays out guidelines to follow when designing, building, and operating boiler fuel handling systems, air handling systems, and combustion control systems. Following its guidelines will certainly significantly decrease the probability of explosions occurring. Another means of explosion prevention includes implementing a boiler operator training program. These enable attendees to better understand operating procedures and equip them with the knowledge to safely control the combustion process, particularly when a furnace explosion is most likely to occur. This training can be done with a combination of classroom instruction along with time on a simulator and may be followed up with hands-on training in the plant itself. Lastly, boiler explosions can be prevented by implementing an effective inspection and maintenance program to locate and repair or replace boiler components, averting the possibility of a potential disaster occurring. Things such as check lists can be used to ensure that nothing is missed. This is a strategy that all pilots must use before starting their planes, and it is now being used in hospitals as well to cut back on the rate of patient infection due to carelessness on the part of hospital staff. Hey, we’re all human, and humans are not perfect. But remember that an ounce of prevention is truly worth a pound of cure, and then some. A properly placed check on the list could mean lives will be saved. _____________________________________________ |