|

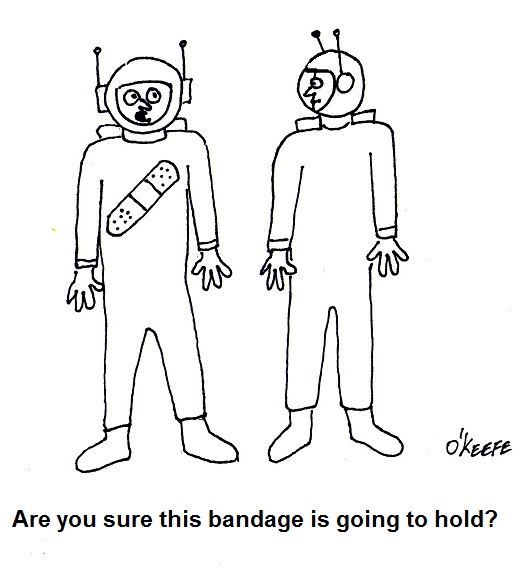

“Danger! Danger, Will Robinson!” What science fiction fan isn’t familiar with this warning cry, or the whirli-gigging robot that shouted it? The Lost in Space robot was a real scene stealer, able to glide effortlessly between Robinson’s spaceship, the vacuum of outer space, and the atmosphere of yet another alien planet without any ill effects. He was a machine. Humans are much more fragile, so the Robinson had to wear pressurized space suits for protection. These suits were pressurized containers for their bodies. Even the smallest leak in a space suit would prove disastrous. In outer space, the big rip in a suit would result in a sudden loss of pressure and expose the wearer’s body to vacuum. The vacuum would rapidly suck all of the oxygen out of the lungs and bloodstream and death would come quickly. On an alien planet with a poisonous atmosphere, the poisonous gases could leak into the suit through the rip. Back here on Earth, leaks in pressurized containers can be just as deadly. A few weeks ago we discussed pressurized containers, otherwise known as pressure vessels, and how they are no stronger than their weakest point. We were also familiarized with the Boyle-Charles Law and the way it can be used to predict how heat increases the pressure of gas within a sealed pressure vessel. In today’s article we’ll discuss some safety concerns, as when a pressure vessel fails and begins to leak. Pressurized vessels can pose a danger for various reasons. Suppose for instance that the substance leaking from it is flammable or toxic. An example would be when propane gas leaking from a storage tank mixes with air surrounding the tank. This can create an explosive mixture, readily ignited by static electricity or a nearby ignition source, such as a spark from a worker’s tool. When a toxic substance is released by a leak into an occupied area, it can be inhaled or come into contact with skin eyes, nose, and mouth, where it can enter the body and injure or kill. It might be obvious that toxic, flammable substances can prove threatening, but it is not quite as obvious that some nontoxic, nonflammable substances can be just as dangerous. For example, a substance can be heavier than air, and as it leaks out of the pressure vessel, it will roll along the floor, sinking into adjacent low spots such as basements and tunnels. This substance would then displace the air, creating a suffocation hazard for anyone who is unlucky enough to be there. Perhaps the most obvious source of danger posed by a pressurized vessel is when its contents rapidly and violently discharge. This scenario presents the same hazards mentioned above, coupled with dangers associated with flying objects and shock waves. For example, if a pressure vessel is not securely held in place and it fails, the rapid release of its contents could literally turn it into a missile careening out of control. I happened to be in close proximity to one of these “unintentional flying objects” one day. The valve broke off an unsecured pressurized gas cylinder of the type that welders use. Its gas escaped with sufficient force to cause the cylinder to fly across a concrete floor and crash through a cinderblock wall. The violent and rapid release of a pressure vessel’s contents also has the potential to create shock waves strong enough to move heavy objects and people, capable of catapulting them through the air. So it’s obvious then that the release of substances from a failed pressure vessel can lead to serious problems, but are there ways to prevent these failures from happening? Yes, there are. We’ll discuss that subject in my next installment where we will discuss, among other things, “overpressure devices.” _____________________________________________ |

Engineering Expert Witness Blog

Published by Philip J. O'Keefe, PE, MLE