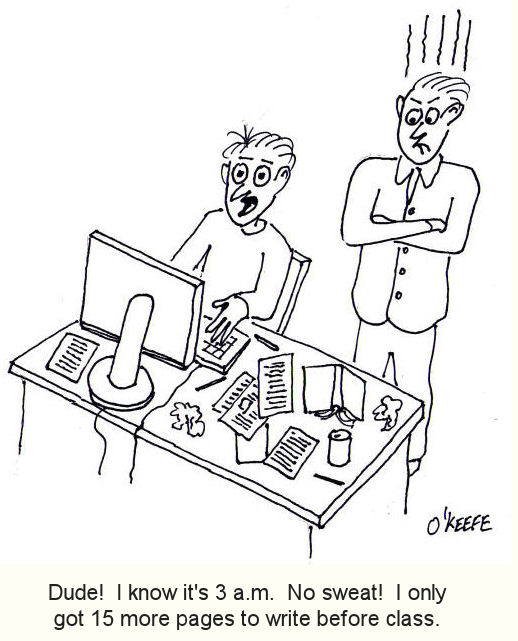

| Did you ever hear the saying, “garbage in, garbage out?” Perhaps you’ve used it yourself at times, as when your teenager insists on writing their 20-page term paper the night before it’s due. Parents, having the benefit of decades of life experience, know that the outcome of a last ditch effort of this type will most likely not turn out well.

This wisdom also applies particularly well to the medical manufacturing process. The FDA is like the parent in this instance, mandating that Design Transfer Procedures be in place to avert the types of disasters which might ensue if the “garbage” philosophy were carried out. Meant to ensure that medical device designs are correctly translated into production specifications for manufacturing, Design Transfer Procedures keep those directly involved with the manufacturing process in check. It is absolutely vital that those involved in manufacturing receive accurate and complete information. Imagine what would happen if an engineer provided a manufacturer with faulty design information. Components could be made to the wrong specifications or of a material that proves toxic to the application. These errors range in negative effect from being costly in terms of dollars wasted to perhaps costing someone their life. A Design Transfer Procedure would ensure that a variety of mishaps do not occur during the transfer process. The procedure is typically overseen by the medical device company’s management. For example, a Design Transfer Procedure would lay out responsibilities of supervisors and managers to make sure the latest revision of electrical schematics, bills of materials, Gerber files, and quality testing procedures are received by the manufacturer of a device’s printed circuit boards. It’s important that the order is received in a timely manner so as not to hold up the manufacturing process. However, it’s much more important that the printed circuit board is made properly, the correct electrical components are placed on it in the correct orientation, and it is tested to make sure it doesn’t malfunction after assembly. Design Change Procedures basically ensure that when changes are necessary, the medical device company follows all the procedures for Design and Development Planning, Design Input, Design Output, Design Review, Design Verification, and Design Validation. Once the changes are reviewed, validated, verified, and approved, they can be incorporated into the original device design. This is where the Design Change Procedure must dovetail with the Design Transfer Procedure to make sure the correct information is provided to the company’s management staff in the procurement, manufacturing, product service, and warehouse departments. This is to make sure they can keep component vendors on track with the changes, maintain sufficient inventory of the changed components, put the right components in the device during assembly, and properly support repair technicians in the field. Yet another aspect of Design Controls promulgated by the FDA comes into play with the establishment of procedures for maintaining a Design History File (DHF). This DHF contains all documentation created during the life cycle of the project, meaning, movement from creation to completion and on into market introduction, sometimes beyond. DHF Procedure sets up protocols for collection and organization of information about the medical device design, starting with design documentation and covering the gamut from design changes, to validation testing, to design verification, and on to design review. All this is done to ensure that the initial product design was developed in accordance with the original design plan and overall product design requirements. _____________________________________________ |

Tags: design changes, design history file, design transfer, engineering expert witness, FDA, Food and Drug Administration, forensic engineer, medical device design controls, medical product, validation testing