For an electric shock to occur, a person must become a part of an electrical circuit in such a way that electric current passes over their skin or through their body. Under certain conditions, even momentary contact with an energized metal object can result in serious injury and even death. According to an article in the American Journal of Industrial Medicine:

From an engineering viewpoint, the body’s electrical resistance is an important variable. Electrical resistance of an object is a measure of how freely electrical current can flow across the object when a voltage is applied across it. Resistance is measured in units called “Ohms.” Resistance of a person’s body can depend on skin dryness, perspiration level, thickness of the skin, the distance that the electrical current travels through the skin, and other factors. The typical human body has a hand-to-hand electrical resistance somewhere between 1,000 and 2,000 Ohms, but resistance across other parts of the body can be much higher. There is a wide variation in body resistance between individuals, so the same voltage level may result in different effects. Most electrical injuries occur from alternating current (AC) at levels above 50 Volts at the low frequencies typically maintained by electric utilities. The North American utilities normally generate power at a frequency of 60 cycles per second. The “cycles per second” unit of frequency is also referred to as “Hertz,” usually abbreviated as “Hz.” At 60Hz frequency, the threshold for perception occurs with electrical currents as low as 0.0001 Amps. The “can’t let go” electrical current for adults is approximately 0.010 to 0.015 Amps. This is the current that causes involuntary muscle contractions severe enough to prevent the person from letting go of the source of the electrical shock. Electric currents as low as 0.050 Amps at 120V, 60Hz, have been known to cause death. Just to give you an idea of how small that current is… a table lamp with one 40 Watt incandescent bulb draws 0.333 Amps from a 120 Volt, 60 Hz household electrical outlet! In the interest of electrical safety, the National Electrical Code (NEC) considers 0.005 Amps at 120V, 60Hz to be the safe upper limit for children and adults. ____________________________________________________________________

|

Archive for July, 2009

A Few Words About Electric Shocks

Sunday, July 26th, 2009The Role Of The Forensic Engineer

Sunday, July 19th, 2009|

Forensic engineers are much like scientific detectives. They are called on to conduct investigations and determine the causes of accidents, fires, equipment failures, safety system malfunctions, and structural collapses. Milton F. Lunch, the former General Council for the National Society of Professional Engineers (NSPE) sums it up very well:

Methods used in forensic engineering investigations, sometimes referred to as “root cause failure analysis,” can include reverse engineering, testing of exemplar components, review of documentary evidence, and examination of alleged failed components. Investigations are conducted in view of engineering principles, standard design practices, industry standards, and regulatory requirements. In the course of a forensic investigation, it’s sometimes impossible to dissect components and devices without destroying any evidence that might be contained within. If destructive examination is unacceptable or impossible, non destructive techniques can be used effectively. Examples of non-destructive examination (NDE) techniques can include the use of a hand-held multimeter to check for electrical continuity or the use of x-ray equipment to reveal telltale signs of failure. Ideally, a forensic engineer should be the one to document, collect, and preserve evidence from the scene of the disputed incident. The outcome of a forensic investigation can sometimes hinge on minute strands of wire or tiny fragments of a component. These small pieces of evidence can be easily overlooked, lost, or damaged by others before the forensic engineer even gets involved. |

The Key To Successful Product Development

Sunday, July 12th, 2009| We’ve all seen instances where someone was making something up as they were going along. And the end result is usually not very good. It’s no different in the product development process. If an engineer designs a product without identifying all requirements, then the product may not meet the expectations of its end user. Worse yet, it may pose a hazard during use and open up a world of potential liabilities. There are three basic requirements for successful product development: functionality, performance, and constraint. A functional requirement specifies the necessary task, activity, or action that the product must be able to achieve. A performance requirement specifies how well the product must perform under specific conditions. A constraint requirement sets out the constraints under which the product must operate. An example would be compliance with government regulations and industry standards.

In every successful product development project the goal is to create requirements that are well defined, well specified, and traceable, meaning each requirement should include the name of its originator and a space for their signature, indicating approval. This eliminates any spinning-of-the-wheels due to misunderstandings, finger pointing, etc. Well defined requirements are, of course, tied into specific design criteria and form the basis of a detailed design specification. These criteria guide the way through all stages of the product’s development. Each requirement should be listed, along with the rationale for its creation and a test method to verify that its objectives have been met. Requirements are only good if they are achievable, verifiable, unambiguous, complete, expressed in terms of a need (not a solution), and consistent. Otherwise, what’s the point? ___________________________________________________________________ |

Finite Elements Analysis (FEA)

Wednesday, July 8th, 2009|

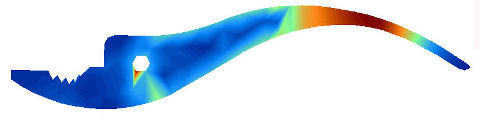

Perhaps you have come across references to “Finite Elements Analysis,” or “FEA,” and wondered what it meant. In the world of engineering, FEA is used to analyze stresses and strains within mechanical component and structural elements. The results of FEA can then be used by an engineering expert witness as an effective demonstrative to convey highly technical concepts to a jury in an easily understood and visually appealing way. In order to conduct FEA, engineers use software to create models of mechanical components. These models are based on scale drawings of the components. Each model includes the physical constraints and material properties of the actual component. After a model is complete, the engineer subjects it to simulated forces. The software creates a colorful map of the results. (See the example below.) The colors represent different stress intensity levels. Blue is an area of low stress and red is an area of high stress. In other words, a red region is where the part is more likely to fail.  FEA of a Plier Handle In a product liability or personal injury lawsuit, the results of FEA can be used in the courtroom to show areas on a machine part where it can become deformed or fracture due to forces placed upon it. FEA can be also be used in patent infringement lawsuits to demonstrate to the jury how a mechanical component in a device actually performs differently from an element in the claimed invention.

___________________________________________________________________

|

The Most Effective Expert Witness Is Born, Not Made

Wednesday, July 1st, 2009 Can there be any question about the fact that credibility is at the heart of every lawsuit? There is no argument that attorneys must appear credible to the jurors and that the evidence they present must be deemed credible. And those that are called to the stand to act as witnesses or experts must, undoubtedly, also be credible. So what makes for a credible expert witness? It may not be what you first think, for although the best expert witnesses demonstrate an uncanny natural ability to teach, they are, by and large not PhD’s, that is to say, they are not professional teachers. Jim McElhaney, senior editor and columnist for Litigation, the journal of the ABA Section of Litigation and author of the article, “Put Simply, Make Your Experts Teach,” which appeared in the May, 2008, ABA Journal may say it best:

In other words, the most effective expert witnesses: 1) Are down-to-earth … people who the jurors can relate to; 2) Are able to convey their message in everyday language, not the jargon of their profession, because people cannot accept as truth what they don’t understand; 3) Are effective at explaining things and enjoy demonstrating to others how things work; 4) Are able to tell a story, paint a picture, whatever it takes to enable the jurors to visualize the point; 5) Will know how to use visual aids, that is, demonstratives, to make the case facts come alive, because jurors need to “see” the facts. In short, your best expert is someone who is an artist capable of explaining the facts, however technical, in the most visual way possible. |