| Last time we looked at the objective of the quality control department in the Production stage, that being to ensure that the end product produced fits all requirements. We learned that to meet this objective a great deal of collaboration must take place in the Development stage between quality control staff and design engineers in order to produce a complete set of instructions for quality control inspection and testing. Now let’s see how these instructions are developed.

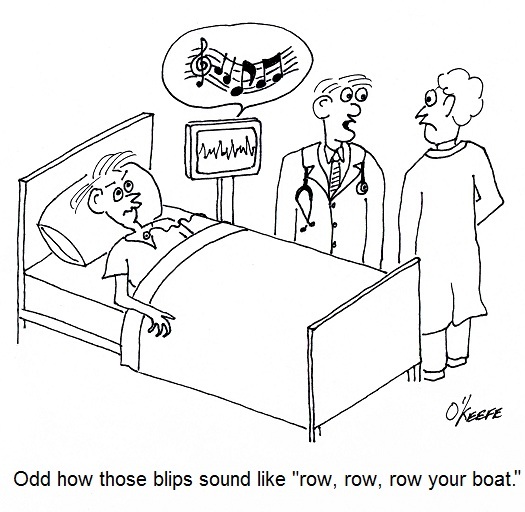

Inspection and test methods are devised by the quality control department to ensure that a completed medical device lives up to its intended use. What good is a diagnostic imaging machine that doesn’t provide accurate internal views of a patient’s body? Or a heart defibrillator that sends electrical energy pulses to a patient’s heart muscles when it’s not supposed to? Quality control instructions are developed to guide inspection and testing methods so they’re performed correctly and consistently during the medical device Production stage. The objective is to catch problems before they occur. For example, it can be specified that the plastic body components of a medical device be visually inspected after they are received from an outside vendor to check for undesirable defects, such as the presence of burrs, cracks, or non-uniform coloration. If anomalies are discovered, they’re documented, and the components are rejected. In other words, they are barred from being used in the assembly process. Quality testing methods are varied. They may involve hooking up the completed medical device to test instruments to simulate all possible modes of operation and any anticipated glitches that may occur during testing. While hooked up, the device’s operation is measured against key parameters to ensure that all is working well, and the data gathered is recorded and analyzed to see if operation is within normal limits. For example, an electric multimeter could be connected to the power cord of the device to measure how much electrical current is being drawn from the wall outlet during operation. If current drawn is too high, it may be indicative of a defective electrical component, and an in depth examination would follow. Generally speaking, if test measurement parameters do not fall within acceptable limits as determined by previously established stakeholder requirements, then the medical device will be rejected by quality control. It will then be sent back to the manufacturing department, along with a detailed inspection and test report explaining why it was rejected. At this point the rejected device is either reworked or disposed of entirely. Next time we’ll continue our discussion on the development of instructions for the Utilization stage, the stage where the medical device is actually put into use by the end user. ___________________________________________ |

Posts Tagged ‘electrical current’

Systems Engineering In Medical Device Design – Instructions, Part 3

Sunday, January 20th, 2013A Few Words About Electric Shocks

Sunday, July 26th, 2009 For an electric shock to occur, a person must become a part of an electrical circuit in such a way that electric current passes over their skin or through their body. Under certain conditions, even momentary contact with an energized metal object can result in serious injury and even death. According to an article in the American Journal of Industrial Medicine:

From an engineering viewpoint, the body’s electrical resistance is an important variable. Electrical resistance of an object is a measure of how freely electrical current can flow across the object when a voltage is applied across it. Resistance is measured in units called “Ohms.” Resistance of a person’s body can depend on skin dryness, perspiration level, thickness of the skin, the distance that the electrical current travels through the skin, and other factors. The typical human body has a hand-to-hand electrical resistance somewhere between 1,000 and 2,000 Ohms, but resistance across other parts of the body can be much higher. There is a wide variation in body resistance between individuals, so the same voltage level may result in different effects. Most electrical injuries occur from alternating current (AC) at levels above 50 Volts at the low frequencies typically maintained by electric utilities. The North American utilities normally generate power at a frequency of 60 cycles per second. The “cycles per second” unit of frequency is also referred to as “Hertz,” usually abbreviated as “Hz.” At 60Hz frequency, the threshold for perception occurs with electrical currents as low as 0.0001 Amps. The “can’t let go” electrical current for adults is approximately 0.010 to 0.015 Amps. This is the current that causes involuntary muscle contractions severe enough to prevent the person from letting go of the source of the electrical shock. Electric currents as low as 0.050 Amps at 120V, 60Hz, have been known to cause death. Just to give you an idea of how small that current is… a table lamp with one 40 Watt incandescent bulb draws 0.333 Amps from a 120 Volt, 60 Hz household electrical outlet! In the interest of electrical safety, the National Electrical Code (NEC) considers 0.005 Amps at 120V, 60Hz to be the safe upper limit for children and adults. ____________________________________________________________________

|