|

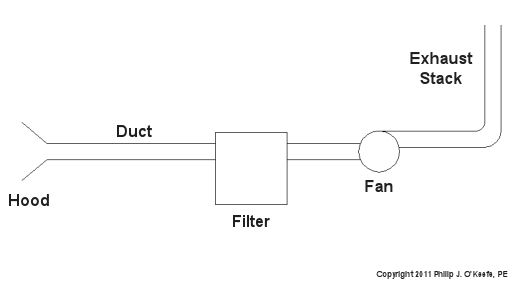

My wife is an aquarist, meaning she keeps aquariums. Three of them. Each contains a different variety of fish housed within its own unique liquid environment. One of these is a 35 gallon tank containing three goldfish. These fish have two unique characteristics that make them especially noteworthy, they are extremely hardy and extremely dirty. Hardly a week can go by between tank changes before the water quality starts to deteriorate, evidenced by cloudy, stinky water. It’s the kind of stink that makes a passerby in the area exclaim, “Who used the bathroom and didn’t turn on the exhaust fan!” Thank goodness for activated carbon. With its proper placement inside the aquarium’s filtration system a cleaner, fresher environment is delivered, both to fish inside the tank and the humans who watch them from outside. Put the carbon in the wrong compartment, however, and the water quality plummets back to its original fetid state within a matter of days. As is true with the proper care of goldfish, it is often necessary within an industrial environment to remove contaminants before the air that contains them is once again dispersed into the general environment. This is where filters and air cleaners come in. They’re generally placed inside the ductwork, somewhere between the hood and fan. Their job is to ensure a good, clean outcome, usually through an external exhaust of some sort. Local exhaust ventilation systems begin with a precisely positioned hood at the source of contamination and end with an exhaust stack located outside the building. Some airborne contaminants being released from the stack are deemed unsafe for the environment, and outdoor air quality standards promulgated by state and federal Environmental Protection Agencies limit their release back into the atmosphere. For this reason the proper use of filtration and air cleaners is crucial. Airborne contaminants are in the form of dusts and vapors. If the issue to be addressed comes in the form of dust, then filters and mechanical separators are commonly used. Filters, like the atmospheric conditions they are meant to address, come in many configurations. They are typically positioned within the local exhaust ventilation system ductwork, as shown in Figure 1 below. Figure 1 – Local Exhaust Ventilation System With Filter The fan draws in air and dust through the strategically positioned hood, located at the source of contamination, then follows a course through ductwork, passing through a filter along the way. The filter contains media with holes tiny enough to allow for air to pass through, but small enough to stop dust particles. The cleaned air is then drawn out of the filter by a fan, which finally exhausts it into an externally positioned stack. Next time we’ll continue our discussion on filtration devices by examining a cyclone. And no, I don’t mean the famous vacuum cleaner, although the methodology is similar. _____________________________________________ |

Posts Tagged ‘vacuum cleaner’

Industrial Ventilation – Local Exhaust Ventilation Filters and Air Cleaners

Sunday, May 1st, 2011Industrial Ventilation – Local Exhaust Ventilation Hoods

Sunday, April 17th, 2011| I’m a husband who occasionally does a little vacuuming, at least of the areas I’m responsible for messing up. It’s not one of my favorite activities, and I particularly hate it when I’m in a hurry and I don’t have enough time to move things out of the way. That’s when an accident is prone to happen, and I end up sucking something besides dirt into the hose. The extra work I’ve just created for myself results in my having to open up the vacuum bag and start sifting through the debris. In the end, I sometimes end up making a bigger mess than the one I started out with.

Vacuums are wonderful tools, when used correctly. And when you think about it, the constituent elements of a household canister vacuum cleaner are similar to those of an industrial local exhaust ventilation system. My home vac is comprised of five main elements, all of which most of you are familiar with: a nozzle, hose, filter, a fan located inside the canister to provide suction, and an exhaust hole, also located within the canister, which serves to discharge newly filtered air back into the atmosphere. Industrial usage local exhaust ventilation systems also typically consist of five constituent elements, namely, a hood, ducts, an air cleaning device, a fan, and an exhaust stack. Like my home vacuum its main objective is to suck something in, namely, contaminated air. Let’s take a closer look at each of the parts. The hood is located at the beginning of the local exhaust ventilation system, and like your home vac’s nozzle, it’s positioned in close proximity to the area requiring cleaning. The objective is of course to capture contaminants at the source. Now placement of the hood within the work area is very important. Ultimately it must be far enough away from the source of contamination so as not to interfere with the work that’s being done, yet close enough to prevent contaminants from escaping. Hoods that almost completely enclose the work area provide the best control of contaminants. Trouble is, they can interfere with the work process. That’s where a specific design of hood, known as a “capture exhaust hood” comes in handy. This type of hood is attached to a flexible duct that resembles a super-sized vacuum cleaner hose. This arrangement provides greater flexibility than a huge, all-encompassing hood, and it also allows the hood to be easily positioned anywhere within the workplace as necessary. Again, placement of a capture exhaust hood is critical to its effective operation. Say for instance that a hood is initially positioned a mere two inches from a source of fumes, then someone comes along and bumps it. It ends up being four inches away from the source, and now it will require around three times the amount of air volume through the system to provide the same degree of capture as it did when it was just two inches away. If the ventilation system isn’t strong enough to draw in this extra volume of air, fumes will escape into the work area, rendering our cleanup efforts ineffective. Next time we’ll discuss the second main component in a local exhaust ventilation system, its ductwork. _____________________________________________ |