|

Did you know that even a perpetual motion machine will eventually come to a stop due to uncontrollable factors? Well, uncontrollable factors are at play in power plants, too. If you recall from our last article, heat rate is industry jargon for gauging how efficiently a coal-fired power plant is operating. We learned that heat rate can be affected by things like missing thermal insulation on pipes and equipment. Missing insulation is, of course, a thing that is under human control and easily corrected, but there are some things that affect heat rate that we just can’t do anything about. They’re called, appropriately enough, uncontrollable factors. Uncontrollable factors exist because anything devised and made by fallible humans who are beholden to the myriad laws of the universe cannot be 100 percent efficient. At their best utility coal fired power plants have an overall efficiency of between 30 and 40 percent. That means 60 to 70 percent of the energy available in the coal gets lost in the process of generating electricity. A terrible waste, right? And yet there’s nothing we can do to trim these losses until improvements in the present level of technology take place. Just as our ability to track microbes is dictated by the strength and accuracy of our magnifying equipment, so are we hampered by the tools we have at our disposal to deal with inefficiencies such as energy losses. So where does this energy get lost due to uncontrollable factors? The first and probably most obvious place to look is the smoke stack. Energy is also lost in three other ways: friction between equipment parts, auxiliary power consumption, and in a piece of equipment known as a condenser. Let’s look at each. In the most basic of terms, when coal is introduced into a power plant boiler it is combined with air and burned. This burning process releases heat energy, but it also forms gases that contain nitrogen and compounds like carbon monoxide and carbon dioxide. There’s also some water vapor formed by moisture in the coal and air. These gases and vapor absorb some of the heat energy released. To keep the combustion process going the gases and vapor must be removed from the boiler by powerful fans and sent up the smoke stack. Now, boilers are designed to absorb much of the heat energy from the gases and vapor that make their way to the stack, but they cannot possibly absorb it all. The result is that a significant amount of heat escapes up the smoke stack into the atmosphere along with the gases. Friction between parts is present everywhere in a power plant. It exists in the bearings on the shafts of motors, pumps, and steam turbines, slowing them down and hindering their operating capacity. Friction also exists where moving water and steam are present, impeding their ability to flow through piping systems. There is even friction working against the steam as it flows through parts in the turbine. Extra energy has to be expended to overcome this friction. This is energy that could be used to generate electricity. Now at some point in your life you’ve probably heard it said, “You need money to make money,” and this is very true. It takes a certain investment of resources to produce a profit-making enterprise. This investment principle holds true for the making of electricity, too. The bottom line is you need electricity to make electricity. Specifically, you have to use significant amounts of electricity to power machinery that is essential to move coal, air, combustion gases, and water through the process of making electricity in the power plant. This is called auxiliary power. It’s the electricity siphoned off by the various pieces of equipment in a power plant in its quest to generate electrical energy to be sold to customers. Another major factor at play in uncontrollable energy losses is in a piece of equipment integral to the very function of power plants: the condenser. It comes into play when water is boiled to make steam which then travels through the turbine, spinning its electrical generator and creating electric power. Unfortunately even the most efficient of steam turbines cannot use 100% of the heat energy coming at it from the steam. You see, after steam leaves the turbine, it’s turned back into water by a condenser so it can be sent back to the boiler to be turned into steam again. One of the reasons that this is done is so that the boiler does not have to be continuously filled with fresh, purified water. Water purification is necessary to keep minerals, seaweed, fish scales, and other nasty things from clogging up and damaging the boiler and steam turbine, and purified water is not as readily available as, say, lake water. The condenser acts as a heat exchanger that is hooked up to the steam turbine exhaust. It has tubes inside of it in which cold water flows, water which is drawn in from a nearby body of water, most often a river or lake. As steam blows across the outside of the cold water tubes in the condenser, it gives up its remaining heat energy and condenses into water again, then it is returned to the boiler to repeat its journey. The river water within the tubes of the condenser flows back into the river, carrying with it the heat energy removed from the steam. That wraps up our discussion about coal power plant efficiency. Next time we’ll discuss a new topic: coal fired power plant furnace explosions. _____________________________________________ |

Posts Tagged ‘coal power plant efficiency’

Coal Power Plants, Far From Perfect

Sunday, July 18th, 2010Coal Power Plant Efficiency

Sunday, July 11th, 2010|

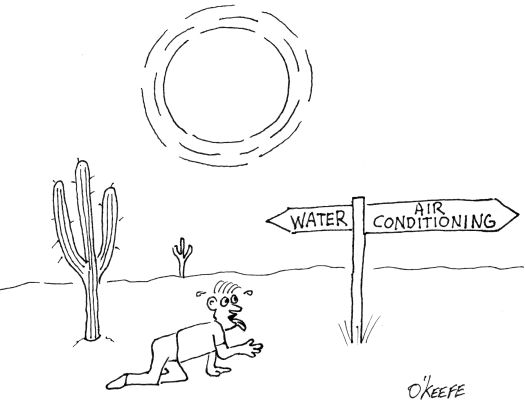

Is there any price a man dying of thirst in the desert would not pay for a tall glass of cold water? What is the point at which Americans will decide they can do without heat, refrigerators, electric lights? My neighbor refuses to run the air conditioner, even when it’s 90 degrees and 90 percent humidity. They have obviously made the choice to sweat and be uncomfortable in their homes rather than pay high utility bills. Most of us are concerned with the environment, but when times are hard like they are now many of us become more concerned with our pocketbooks. Just as we need to make our financial ends meet, so do energy suppliers. Without a certain level of profit, their service to us will decline, and regular, dependable delivery of their precious commodities to us will suffer. If they were to go out of business, what then? Reading by candlelight may be romantic for a night or two, but nights on end? Let’s consider the energy provided by coal-fired power plants, for example. They’re in the electric utility business, and they provide us with the lion’s share of our energy. To keep a handle on operating costs, power plant engineers monitor how many British Thermal Units (BTUs) of heat energy are going into the power generation process versus how many kilowatt-hours of electricity are coming out. What’s a BTU and what does it matter to us? Well, it’s the amount of heat energy your kitchen stove uses to raise the temperature of one pint of water by one degree Fahrenheit. As for a kilowatt-hour, that’s a thousand watts of power produced over the space of an hour– enough to light ten 100 watt light bulbs. Now that we’ve explained the key term, we can explore the notion of heat rate, terminology very important to efficient power plant operation. Heat rate is simply the ratio of BTUs to kilowatt-hours. So what’s the importance of monitoring heat rate? For one thing, in order to get the most bang for your buck you want to keep the heat rate as low as possible. When the heat rate is high, you’re burning more coal than you have to because you’re wasting heat energy. This results in higher electricity costs to the consumer. This is exactly the situation at play when low sulfur coals are used as compared to the better burning coals of yester-year. So where does the wasted heat energy go if it isn’t being converted into electrical energy? For one thing, it can be lost through steam and water leaks in the power plant piping system. There are other losses too. Another way to lose heat energy is when thermal insulation is missing from pipes, causing heat to escape into the atmosphere. The opposite side of inefficiency is presented by the problem of too much heat energy building up, unable to be transferred to the steam. This is the result if ash is allowed to accumulate inside the boiler, acting as a thermal insulator. The heat has nowhere to go except up the smoke stack and into the atmosphere. Needless to say it’s important to keep heat rate as low as possible by keeping power plant equipment insulated and in good repair. But there are some things that affect heat rate that we just can’t do anything about, they’re known as “uncontrollable factors,” and we’ll learn about them next week. _____________________________________________ |