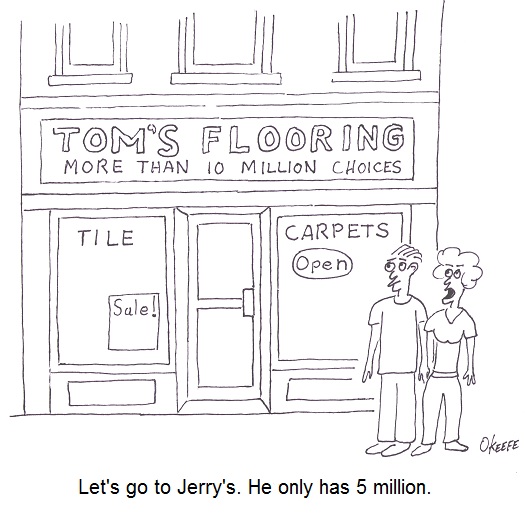

| Done any remodeling lately? If you have, you’ve been faced with countless choices regarding design and materials. Even a relatively simple decision such as putting in hardwood flooring requires many considerations. What type of wood? What grade? How about the stain? Should it be factory stained and sealed, or should the flooring be installed by single board, then stained and sealed in place? Ultimately, your decision is based on your requirements with regards to cost, durability, and personal style.

Now imagine the decision making process that is required to produce a medical device. We’ve been discussing this complex process during our series on medical device design utilizing the systems engineering approach, a systemized approach to product development, design, and manufacture that is used within many manufacturing arenas. Its objective is to relate the requirements for manufacture, regulatory compliance, sale, use, and maintenance of the product to specific design criteria for functionality, durability, and safety. By doing so, the systems engineering approach ensures that the product meets or exceeds all requirements. Last time we wrapped up our discussion on the Development stage of systems engineering by discussing field testing of medical devices assembled during Preproduction. Problems encountered during this phase result in a comprehensive review of the device design and instructions. When all issues have been resolved, things move on to the manufacturing phase and full commercial production. During the Production stage, engineers make continual assessments of the manufacturing process and ongoing adjustments are made to the device design and manufacturing protocol as necessary, this due primarily to changing stakeholder requirements regarding cost reduction. In the competitive marketplace, cost reduction is a never-ending quest to maintain profitability in view of changing economic and market conditions, and this must be done without compromising the quality, safety, and effectiveness of the device. For example, suppose a medical diagnostic imaging machine was designed to be fitted with a machined metal gear in one of its mechanisms. The manufacturer specifies that a $10 decrease must be made in production costs so it can continue to be sold at an acceptable profit margin. After reviewing the design, engineers discover that substitution of a molded plastic gear would reduce manufacturing cost per machine by $12. This is a common scenario, as plastic parts are often substituted for metal to save on cost. Plastic versus metal? How can that be an acceptable swap? In many cases, it can be. Mechanical stressors are analyzed, and if the plastic gears meet durability requirements as well as their metal counterpart, they are substituted. During the Preproduction phase these plastic gears are used in both lab and field testing, where they are put through the rigors of real world use. If they perform acceptably, they are made a permanent part of the device’s design and used in commercial production. Next time we’ll continue our look at the Production stage to discover another way that systems engineering can facilitate cost reduction to meet stakeholder requirements. ___________________________________________ |

Posts Tagged ‘durability’

Systems Engineering In Medical Device Design – Concept Evaluation

Monday, December 17th, 2012| How many times have you bought something and lugged it home, only to discover that it didn’t work as advertised? These days this scenario is all too common. Chances are it was developed haphazardly and rushed into production without adequate research and testing. A chief contributor to the product’s not living up to expectations is very often the result of a poor beginning. In its concept and development stages, design engineers failed to use a systems engineering approach.

Last time our discussion of the Concept stage of systems engineering identified stakeholder requirements as being of three basic types, serving the needs of functionality, performance, and constraint. Once identified, these requirements were incorporated into a detailed specification that is approved by all stakeholders involved, then used to devise alternate medical device concepts in order to really size things up. Let’s now move on to the Development stage of the design process to see how the alternate concepts are evaluated. The Development stage of the systems engineering approach to medical design begins with research and development of alternate device concepts. Stakeholder requirements as defined in the original product specification are used to guide the process, then mockups and prototypes of the alternate concepts are built, tested, and analyzed in view of the requirements. Considerations such as cost, ease of manufacture, operation, durability, and potential risk of harm to users are evaluated. As often happens, the best alternate concept satisfies all but a few of the specified requirements, resulting in a “good enough” scenario. That is to say, if stakeholders can agree the requirements not met aren’t all that important in the scheme of things, they may be willing to remove them from the specification, thus approving the concept for further development. If an agreement such as this cannot be reached, it may be necessary to return to the Concept stage and begin the entire process again. This re-evaluation of the process should result in a set of requirements that are further refined and from which better options in alternative concepts can be developed. Next time we’ll continue our discussion of the Development stage and see what it takes to finalize design and begin manufacture. ____________________________________________ |