| How many times have you bought something and lugged it home, only to discover that it didn’t work as advertised? These days this scenario is all too common. Chances are it was developed haphazardly and rushed into production without adequate research and testing. A chief contributor to the product’s not living up to expectations is very often the result of a poor beginning. In its concept and development stages, design engineers failed to use a systems engineering approach.

Last time our discussion of the Concept stage of systems engineering identified stakeholder requirements as being of three basic types, serving the needs of functionality, performance, and constraint. Once identified, these requirements were incorporated into a detailed specification that is approved by all stakeholders involved, then used to devise alternate medical device concepts in order to really size things up. Let’s now move on to the Development stage of the design process to see how the alternate concepts are evaluated. The Development stage of the systems engineering approach to medical design begins with research and development of alternate device concepts. Stakeholder requirements as defined in the original product specification are used to guide the process, then mockups and prototypes of the alternate concepts are built, tested, and analyzed in view of the requirements. Considerations such as cost, ease of manufacture, operation, durability, and potential risk of harm to users are evaluated. As often happens, the best alternate concept satisfies all but a few of the specified requirements, resulting in a “good enough” scenario. That is to say, if stakeholders can agree the requirements not met aren’t all that important in the scheme of things, they may be willing to remove them from the specification, thus approving the concept for further development. If an agreement such as this cannot be reached, it may be necessary to return to the Concept stage and begin the entire process again. This re-evaluation of the process should result in a set of requirements that are further refined and from which better options in alternative concepts can be developed. Next time we’ll continue our discussion of the Development stage and see what it takes to finalize design and begin manufacture. ____________________________________________ |

Posts Tagged ‘research and development’

Systems Engineering In Medical Device Design – Concept Evaluation

Monday, December 17th, 2012Food Manufacturing Challenges

Sunday, September 18th, 2011| Some people just have a knack in the kitchen, and my wife is among them. She transforms raw ingredients into the most amazing culinary delights, almost like she’s waving a magic wand. The finished products are works of art, hand crafted with tender loving care, and lucky me, I get to feast on them regularly!

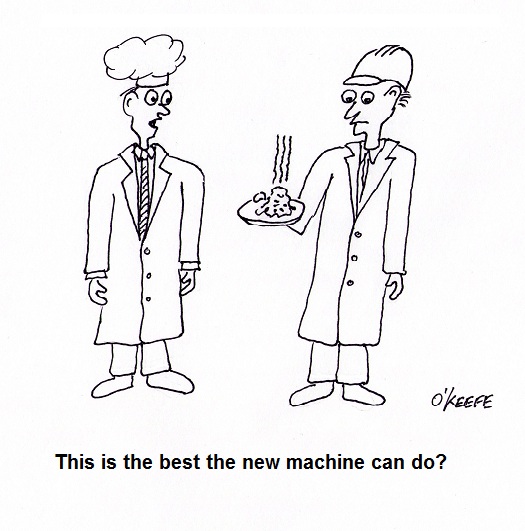

During the course of my engineering career I’ve been employed within many industries, and at one point I made the decision to leave the electric utility industry and enter into the world of food manufacturing. I accepted the position of Plant Engineer with a wholesale manufacturer of baking ingredients and frozen pastry products. My main responsibility was the design of food manufacturing equipment and their production lines. What I had expected to be a relatively straightforward process soon proved to be more challenging. I was no longer working with hard metal as my raw material, that is, gears, nuts, and bolts, but a whole new arena of things described by adjectives such as gooey and pastey. Engineers don’t typically create food products, and let’s face it, you probably wouldn’t want to eat anything that I cooked anyway! But an engineer working within a food manufacturing plant must act as a liaison between the worlds of engineering design and the culinary arts. Now food manufacturers typically hire professional chefs to develop new products in their research and development (R&D) kitchens. Like my wife, they’re well qualified to produce wonderful hand-made culinary delights. The sticky part comes in when their small batch recipes and preparation techniques don’t translate smoothly to the world of mass production. When it comes to handling food, human fingers are far superior to metal machinery, and raw ingredients behave differently for each. Herein lies much of the challenge for design engineers within the food industry. How do you design equipment and production lines to make huge quantities of food that look and taste as good as the prototype products made by hand in the R&D kitchen? Next week we’ll find out. ____________________________________________ |