Last time we opened our discussion on the Development stage of the systems engineering approach to medical device design and discovered that the best design concept is the one that meets all stakeholder requirements. Let’s use the flow chart shown in Figure 1 to illustrate what comes next in this stage.

Figure 1To begin the transformation from concept to completed design, engineers review documentation created during the Concept stage, including design notes, concept sketches, and of course the final requirements specification which has been approved by all stakeholders. Once the review is completed, it serves as a guide to the creation of detailed design documentation, including mechanical drawings, electrical schematics, and wiring diagrams. A bill of materials, or BOM, is also created, listing all parts needed to produce the final product. Each part designated within the BOM is associated with a specific manufacturer or supplying vendor, and each has been qualified with regard to price, availability, functionality, and quality. The design documentation and BOM are also subject to a review by a fresh set of eyes, engineers who have no involvement in the project. If they should discover a problem, the design is rejected and sent back to the design engineers for revision. This process of evaluation and correction are repeated until the design successfully passes a final review. Only then can the fully approved finished design move on to the production stage. Next time we’ll continue our discussion of the Development stage, moving our concept medical device further along its journey to the Production stage. ___________________________________________ |

Posts Tagged ‘electrical schematics’

CAD To The Rescue

Sunday, June 20th, 2010|

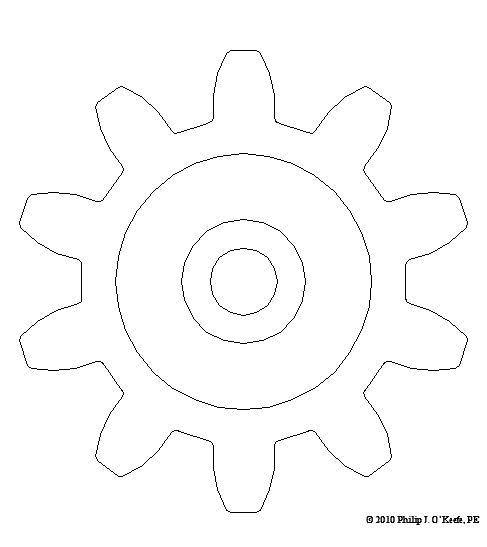

Remember Mike, the dad on The Brady Bunch, forever hunched over his drafting table while Alice, the housekeeper, regales him with yet another tale of Brady kids gone rambunctiously wrong? Although he seemed very attached to his mechanical pencil and rolls of architectural drawings, he’d have been far better off with a computer and CAD software. CAD, or Computer Aided Design, makes the life of architects, engineers, and designers of various sorts a whole lot easier. It’s been around for a few decades now, and its applications just keep getting broader. Once familiar with the workings of this software, one can produce technical diagrams in record time, and mistakes are just a delete button away from being eradicated. In fact, it’s very much like a word processor for graphics, not words. Nowadays, for all intents and purposes, the drafting table, pencils and rulers are pretty much extinct from usage by architects and engineers, much like The Brady Bunch television show. Remember the days of typewriters and carbon paper? If you do, you just dated yourself, because these haven’t been in general usage for quite some time. Word processing software and computers in general have relegated these instruments to become dusty on the shelves of historical museums. Why laboriously copy an object by hand, over and over again, when you can cut and paste your way to duplication perfection using CAD? There are even special features within CAD that allow for replication of a drawing detail in an array, meaning it is automatically replicated a specified number of times while being spaced precise distances apart along a straight line or circle. Let’s look at a simple example of how CAD makes our life so much easier. Figure l shows a single gear tooth, drawn in CAD. Figure 2 shows the tooth automatically replicated ten times and displayed in a circular array, each tooth a precise space away from its nearest neighbor. Figure 3 shows all of the gear teeth connected together with lines to form a completed drawing. Before the advent of CAD, an engineer would have had to replicate each gear tooth by hand using physical tools like a compass, pencil, and scale ruler. Figure 1 – A Single Gear Tooth Drawn With CAD

Figure 2 – A 10 Tooth Circular Array Created With CAD

Figure 3 – A Completed CAD Drawing of a 10 Tooth Gear

Another useful feature of CAD is how it can be used to annotate drawings, that is, put notes, labels, and dimensions on them. This nifty feature has rendered precise penmanship obsolete. Gone are the days when student engineers labored by hand and pencil to produce precisely the lettering and numbering conventions that are acceptable within their discipline. Poor penmanship could be disastrous to both the engineer’s career and the final product due to the difficulty it would present in reading and proper interpretation. CAD produces a level of uniformity never before possible, but of course one still needs to know how to spell! If you look back through my blog articles, you’ll see many diagrams that I created with CAD software, thus rendering complicated technical concepts easier to understand. Illustrations are most often easier to understand by the general population than the written word, and as one of my past blogs was titled, A Picture is Worth a Thousand of Them, “them” being words, of course. I also routinely use CAD software in other aspects of my profession to create everything from electrical schematics to flow charts, PowerPoint presentations slides, and engineering expert reports. _____________________________________________ |