|

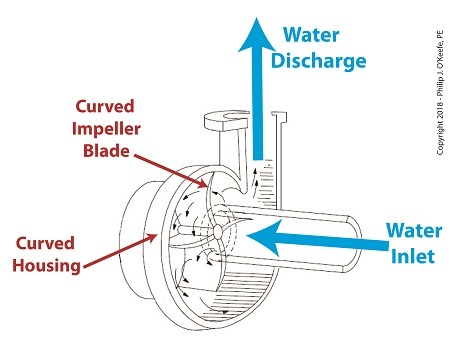

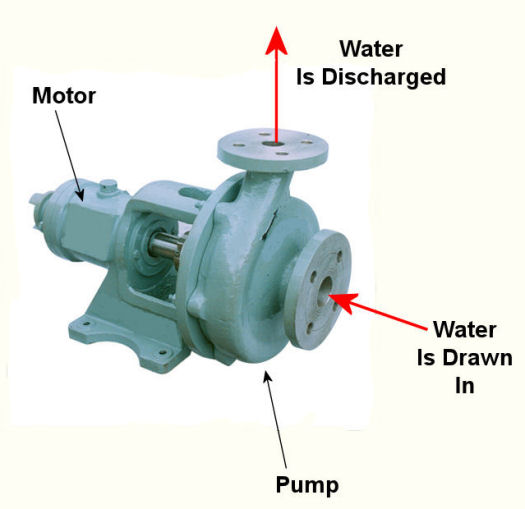

Last time we discussed how the curved features of a centrifugal pump are key to its functionality. Today we’ll examine a centrifugal pump’s impeller action and see how it creates a volatile environment inside the pump in which cavitation bubbles flourish. Centrifugal Pump Impeller Action

Inside a centrifugal pump both low and high pressure areas are created, chiefly due to the action of the pump’s spinning impeller. Low pressure is created at the water inlet in a way very similar to what happens when you pull the plug on your bathtub. With the plug removed the drain opens and a tiny whirlpool forms, causing water to get sucked into the plumbing for discharge. The same thing happens inside a centrifugal pump due to tumultuous internal water movement. The spinning impeller vigorously moves water from inlet to discharge. As water is discharged, a void, or vacuum, is created inside the pump, causing water at the inlet to get sucked inside at low pressure, very much like when you suck liquid through a straw. As water moves inside the housing, it comes into contact with the rotating impeller itself. This impeller is comprised of multiple spiral curved blades with a volute shape, made to maximize efficient movement of water. They use the power of centrifugal force to create a high pressure environment, and water is flung at high speed towards the pump’s outlet, where it is then discharged. Next time we’ll see how the coexistence of low and high pressures within the centrifugal pump housing create the problem of cavitation bubbles. opyright 2018 – Philip J. O’Keefe, PE Engineering Expert Witness Blog ____________________________________ |