Archive for the ‘power plant training’ Category

Thursday, September 27th, 2018

|

Last time we introduced the phenomenon of uncontrollable factors as they exist within coal fired power plants. They inevitably result in lost energy in a number of ways, the most obvious of which is probably the smokestack, where lost energy is seen literally going up in smoke through the stack.

Energy Going up in Smoke Through the Stack

When coal is introduced into a coal fired power plant’s boiler, it’s combined with air, ignited, and begins to burn. This burning process releases some useful heat energy to fuel our power grids, but the rest goes up in smoke through the stack, releasing the products of the combustion process, including nitrogen, carbon monoxide, carbon dioxide, and water vapor into the atmosphere.

Next time we’ll discuss friction, another factor which results in power plant energy loss.

Copyright 2018 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: boiler, combustion process, energy, power plant, stack

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, power plant training | Comments Off on Energy Going up in Smoke Through the Stack

Wednesday, September 5th, 2018

|

You know that little red guy that bobs in and out of a glass of water, seemingly without end? He’s an example of a non-perpetual motion device, because even he will eventually come to a stop due to something known as uncontrollable factors. Uncontrollable factors are a hindering factor in coal fired power plants, as well, most notably by a measure of efficiency known as heat rate.

Uncontrollable Factors At Play

The term heat rate is industry jargon for gauging how efficiently a coal fired power plant is operating. We previously learned that heat rate can be affected by things like missing thermal insulation on pipes and equipment. Of course missing insulation can easily be corrected because it’s directly under human control, but heat rate can be affected by many factors we can’t do anything about, known as uncontrollable factors.

Human fallibility is behind the phenomenon of uncontrollable factors, and because we are less than 100% accurate and efficient, so is anything that we make. At their best utility coal fired power plants have an overall efficiency of between 30 and 40 percent, which means 60 to 70 percent of the stored energy inside coal is wasted and doesn’t go towards generating electricity.

Unfortunately there’s nothing we can do to eliminate these waste factors until improvements are made in the present level of technology. When we look through a microscope to view microbes we’re limited by the accuracy of the equipment, and in a similar way we are limited in everything we do as humans by the equipment we’ve built. That includes energy efficiency within power plants.

We’ll start identifying the uncontrollable factors that affect power plant performance next time.

Copyright 2018 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________

|

Tags: efficiency, engineering, heat rate, uncontrollable factors, utility power plants

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, power plant training, Product Liability | Comments Off on Uncontrollable Factors In Coal Fired Power Plants

Monday, May 14th, 2018

|

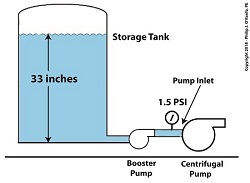

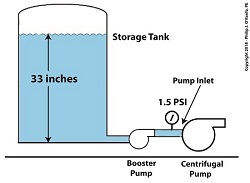

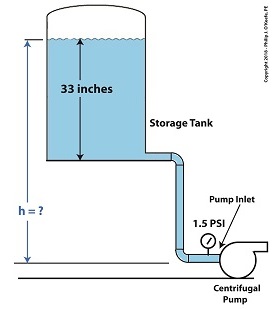

In our last article, we looked at an example problem involving a cavitating centrifugal pump that was drawing water from a storage tank. The bottom of the storage tank was sitting at the same level as the centrifugal pump’s inlet. The water level in the tank could not be increased to raise the pump inlet pressure, and thus eliminate the cavitation. So, the problem was solved by elevating the tank with respect to the pump inlet. Okay, what if the tank could not be elevated? How do we stop the centrifugal pump from cavitating? Well, we can install a booster pump between the tank and the centrifugal pump.

A booster pump is, as its name implies, a special kind of pump that is used to boost, or raise, water pressure flowing in a pipe. With regard to our example problem in the preceding article, the cavitating centrifugal pump inlet water is at 108ºF and a pressure of 1.2 pounds per square inch (PSI).

Reducing Cavitation With A Booster Pump — Before

Referring to the thermodynamic properties of water as found in tables appearing in engineering texts, we determine that if we keep water temperature at 108ºF but raise the pressure at the pump inlet from 1.2 PSI to 1.5 PSI we can stop the centrifugal pump from cavitating. We can install a booster pump to boost the pressure by the required 0.3 PSI and say goodbye to our cavitation problems.

Reducing Cavitation With A Booster Pump — After

This wraps it up for our series on cavitation in pumps. Next time, we’ll begin learning about some different topics.

Copyright 2018 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: booster pump, cavitation, centrifugal pump, engineering, pump inlet pressure, thermodynamics, water pressure, water tank elevation, water tank level, water temperature

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, power plant training, Product Liability | Comments Off on Reducing Cavitation With A Booster Pump

Monday, May 7th, 2018

|

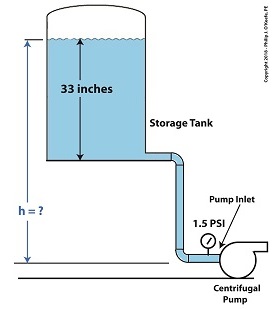

Last time we learned that the risk of damaging cavitation bubbles forming at a centrifugal pump’s inlet can be eliminated by simply increasing the water level inside the tank. Today we’ll do the math that demonstrates how reducing cavitation can be accomplished by raising tank elevation.

Reducing Cavitation by Raising Tank Elevation–Before

In our example we’ll suppose that we’re having a problem with cavitation bubbles forming at the inlet, where water temperature is 108ºF and water level inside the tank stands at 33 inches. We are using the formula,

P = γ × h (1)

Equation (1) was introduced previously to correlate water pressure, P, with the specific weight of water, (0.036 pounds/inch3), and the height, h, of the water surface in the tank. If h is 33 inches, then we obtain,

P = (0.036 pounds/inch3) × (33 inches) = 1.2 pounds/inch2 (2)

So, the weight of the water in the tank exerts a pressure of 1.2 pounds per square inch (PSI) at the bottom of the tank and the pump inlet when it sits at the same elevation as the tank.

We know that if we increase the water depth in the tank relative to the pump inlet, we can raise the pressure at the pump inlet in accordance with equation (1). Raising the pressure will eliminate the cavitation bubbles that can form there. But, our tank is of fixed volume, and we can’t add more water to raise water depth beyond 33 inches. However, we can increase the elevation of the tank with respect to the inlet, which will produce the same effect. We’ll use equation (1) to determine the tank elevation, h, that will provide the needed increase.

Referring to the thermodynamic properties of water as found in tables appearing in engineering texts, we determine that if we keep water temperature at 108ºF but raise the pressure at the pump inlet from 1.2 PSI to 1.5 PSI, while maintaining current water depth in the tank, cavitation will cease. In other words, we need to increase P by 0.3 PSI.

Example of Reducing Cavitation by Tank Elevation–After

Plugging our known values into equation (1) we solve for h,

0.3 PSI = 0.036 pounds/inch3 × h (3)

h = 0.3 PSI ÷ 0.036 pounds/inch3 (4)

h = 8.3 inches (5)

Cavitation will cease when we elevate the tank by 8.3 inches with respect to the pump.

Yet another means of increasing inlet pressure is to install a booster pump. We’ll talk about that next time.

Copyright 2018 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________

|

Tags: cavitation, centrifugal pump, engineering, pump inlet, specific weight of water, stopping cavitation, thermodynamics, water depth, water pressure, water tank elevation

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, power plant training, Product Liability, Professional Malpractice | Comments Off on Reducing Cavitation by Raising Tank Elevation

Tuesday, April 24th, 2018

|

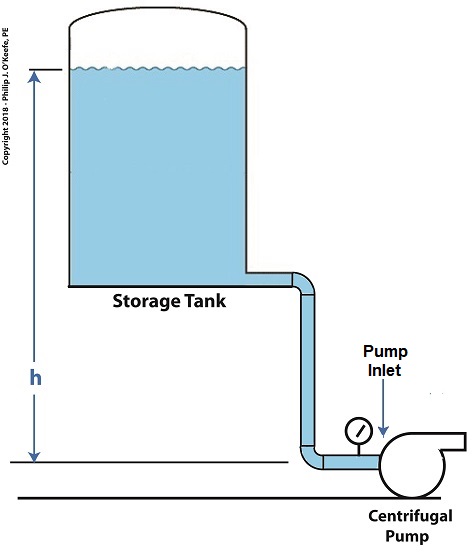

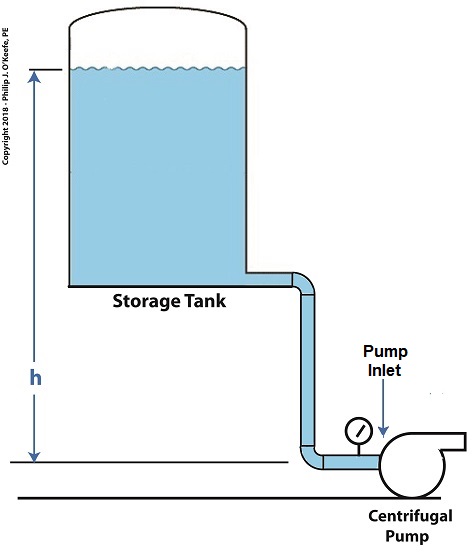

In our last blog we learned of one way to prevent cavitation bubbles from forming at a centrifugal pump inlet when we simply added more water to the storage tank, thereby raising the water level and with it the water pressure at the pump’s inlet. Today we’ll discuss another way of reducing cavitation, by increasing water tank elevation.

Reducing Cavitation by Increasing Water Tank Elevation

As presented previously, water pressure, P, at the bottom of the tank is determined by the engineering formula,

P = γ × h

where γ is the Greek symbol gamma,representing the specific weight of water, (0.036 pounds/inch3), and h is the depth of the water inside the tank.

This formula applies to another scenario as well, that of raising the entire tank’s elevation with respect to the pump, as shown in the illustration. Here h is the height of the surface water in the tank with respect to the pump’s inlet. The equation tells us that the higher the tank is elevated, the greater the pressure at the inlet and the less chance there is of cavitation bubbles forming.

How high do we need to elevate the tank? We’ll do the math next time.

Copyright 2018 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________

|

Tags: cavitation, cavitation bubbles, specific weight, tank elevation, tank pressure, water. engineering

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, power plant training, Product Liability | Comments Off on Reducing Cavitation by Increasing Water Tank Elevation

Monday, April 16th, 2018

|

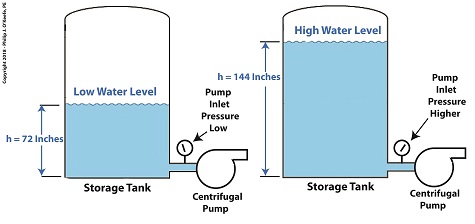

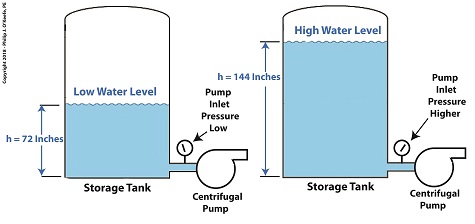

Ever hear the old saying, “There’s more than one way to cook a goose”? The statement is meant to encourage creative thinking when problem solving. This forward thinking can be applied to the problem of destructive cavitation bubbles as well. Finding ways to reduce cavitation is something engineers are well versed in. As discussed in our last blog, one way to prevent cavitation is by lowering water temperature at a centrifugal pump’s inlet. But sometimes that isn’t possible. Today we’ll discuss another way, reducing cavitation by increasing water pressure.

One way to Reduce Cavitation by Increasing Water Pressure

If you’ve ever seen a movie featuring divers, you’ll no doubt be aware that the deeper a diver goes, the more water pressure there is bearing down on him from above. The same goes for a centrifugal pump’s storage tank. The higher the water level inside the tank, the higher the pressure bearing down on the pump’s inlet, which is located at the bottom of the tank. This is the area in which cavitation bubbles are likely to form. The mathematical equation that illustrates this relationship is,

P = γ × h (1)

where, P is water pressure at the bottom of the tank, γ is the Greek symbol gamma, representing the specific weight of water, (0.036 pounds/inch3), and h is the depth of the water inside the tank.

Let’s see what happens when we increase the water level, h, from 72 inches, shown on the left, to 144 inches, on the right.

P = (0.036 Lb/in3) × (72 in) = 2.592 PSI (2)

When the water level is raised to 144 inches, P becomes,

P = (0.036 Lb/in3) × (144 in) = 5.184 PSI (3)

We see that by raising the water level in the tank from 72 to 144 inches, pressure at the bottom of the tank where the inlet is located is increased from 2.592 PSI to 5.184 PSI, pounds per square inch.

Next time we’ll see how simply elevating the tank has an impact on cavitation.

Copyright 2018 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: cavitation, cavitation bubbles, centrifugal pump, engineering, pressure, pump inlet, specific weight of water, storage tank, temperature, water level

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, power plant training, Product Liability | Comments Off on One way to Reduce Cavitation by Increasing Water Pressure

Monday, April 9th, 2018

|

As we learned previously, cavitation bubbles form at a centrifugal pump’s inlet when the thermodynamic properties of water, namely temperature and pressure, are right. Today we’ll see how just manipulating water temperature can control cavitation.

Manipulating Water Temperature to Control Cavitation

Some centrifugal pumps draw water from an external heat source such as a heat exchanger in order to provide heat to buildings, generate power, and perform manufacturing processes. On some exchangers heat is applied at a fixed rate and can’t be varied. On others heat can be varied by using a heat exchanger fitted with a temperature control. This makes it easy to reduce or lower water temperature introduced at the pump’s inlet. If the temperature is kept low enough relative to the pressure at the inlet, cavitation bubbles won’t form.

Let’s say water enters the pump’s inlet from a heat exchanger at 59ºF and internal pump pressure is 0.25 pounds per square inch (PSI). With these parameters in place water boils and cavitation bubbles will form in the pump inlet. But if the heat exchanger is adjusted so that temperature is lowered by a mere two degrees to 57ºF, cavitation ceases. This is in accordance with the boiling points of water, listed for various pressures and temperatures, as published in engineering thermodynamic texts.

If it’s not possible to lower water temperature at the pump inlet, an alternate method to control cavitation is to raise water pressure, which can be accomplished in different ways. We’ll review those options next time.

Copyright 2018 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: cavitation, centrifugal pump, engineering, heat exchanger, pressure, temperature, temperature control, thermodynamics

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, power plant training, Product Liability | Comments Off on Manipulating Water Temperature to Control Cavitation

Monday, April 2nd, 2018

|

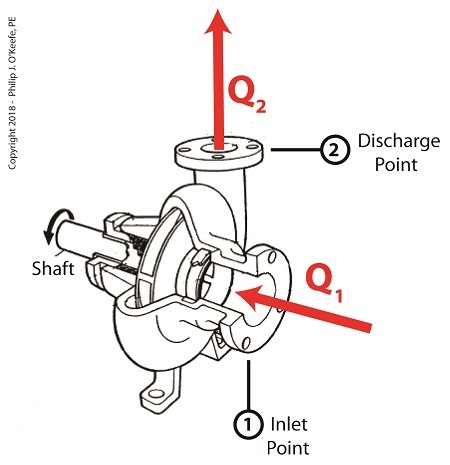

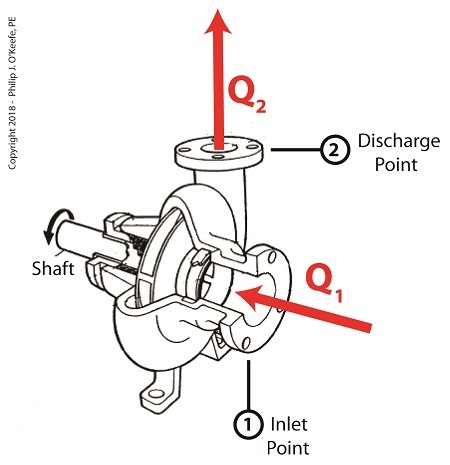

Last time we learned how cavitation degrades a centrifugal pump’s performance by restricting and reducing the water flow at the pump’s inlet where these destructive bubbles are formed. Today we’ll see that despite the fact these cavitation bubbles return to a liquid water state further along in the pump’s high pressure section when they implode, the water flow within the pump remains the same. This is true because of the engineering principle of continuity, which holds that the water flow rate within a pump or any other closed system remains the same throughout that system. What goes in must come out.

Continuity has to do with the rate of water flowing through pipes, valves, and pumps within a plumbing system. As water flows through a centrifugal pump, its flow rate is measured as the volume of water that moves past a certain point in the pump per unit of time. Suppose for example that during one minute of elapsed time the volume of water flowing through at the inlet point is found to be five gallons. This then becomes the system’s flow rate of 5 gallons per minute. We’ll call this flow rate Q1.

The Principle of Continuity – What Goes In Must Come Out

The principle of continuity states that this flow rate Q1 must remain the same throughout the pump. If this were not true, any observed difference in water volume would mean water is somehow either lost or created between the pump’s inlet and discharge. This is an impossibility if the pump is an intact enclosed system, absent any other inlet points or leaks. So according to the principle of continuity, Q1 must equal Q2, the flow rate at pump discharge.

When cavitation occurs at the pump’s inlet, Q1, these steam bubbles restrict water flowing into the pump. Although these bubbles will later implode and return to a liquid water state further along the pump system, this change will not affect the flow rate of the water within the pump. The flow rate established at intake will remain the same at pump discharge, Q2.

Next time we’ll see how cavitation in centrifugal pumps can be prevented.

Copyright 2018 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: cavitation, centrifugal pump, continuity, flow rate, gallons per minute, plumbing, pump performance, valves

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, power plant training, Product Liability | Comments Off on The Principle of Continuity – What Goes In Must Come Out

Sunday, March 25th, 2018

|

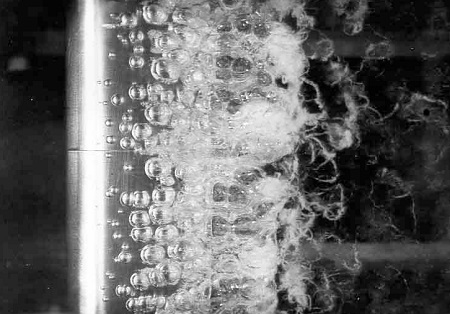

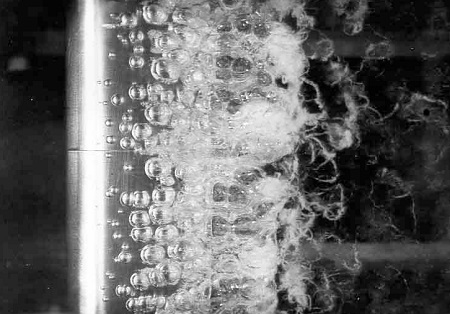

Previously we learned how cavitation bubbles cause noise, vibration, and damage to centrifugal pumps. Today we’ll see how cavitation bubbles degrade pump performance in a centrifugal pump’s low pressure section.

Cavitation Bubbles Degrade Pump Performance

During cavitation multitudes of tiny steam bubbles form and become suspended in the water that’s constantly flowing through a working centrifugal pump. These bubbles decrease the density of the water because steam bubbles are lighter and occupy less space than liquid water. This decrease in the water’s density causes the pump to be less efficient, because for any given amount of horsepower that’s conveyed to the pump’s impeller by an external power source, the pump’s ability to promote water discharge is compromised due to the bubbles.

As an example, let’s say that when the bubbles of cavitation form inside a pump, the pump’s water-bubble ratio is a mixture of 70 percent liquid water and 30 percent steam bubbles. That’s a lot of bubbles, and they act to restrict water flowing through the pump’s inlet, reducing flow rate by 30 percent.

As water moves from the inlet towards the spinning impeller, all the steam bubbles implode in on themselves in the high pressure section of the pump. They return once again to their liquid state and join the rest of the water flowing towards pump discharge, but despite this the pump’s flow rate remains reduced at the discharge.

We’ll find out why this is true next time when we discuss the engineering principle of continuity.

opyright 2018 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: cavitation, centrifugal pump, continuity, pump performance, steam bubbles, water density

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, power plant training, Product Liability | Comments Off on Cavitation Bubbles Degrade Pump Performance

Monday, March 12th, 2018

|

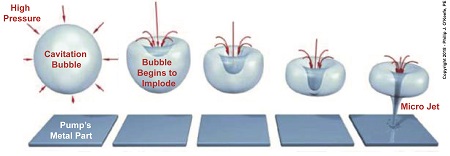

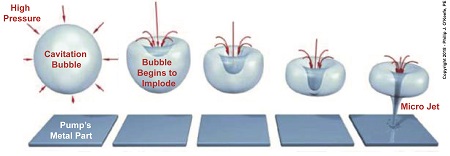

Last time we learned how both low and high pressures exist within a single centrifugal pump, and if water pressure at the inlet is low enough, the cavitation process begins. Today we’ll see how these rapidly imploding water vapor bubbles create serious problems in the pump’s high pressure area.

Rapidly Imploding Bubbles Create Problems

Water flows from low pressure at a centrifugal pump’s inlet to high pressure upstream when it meets up with the pump’s impeller. This high pressure causes cavitation bubbles formed at the inlet to rapidly implode, that is, collapse in on themselves. Implosion occurs because pressure outside the bubbles is much greater than the pressure inside them. This pressure difference exists because the bubbles were formed in the low pressure area of the pump.

When cavitation bubbles meet up with high pressure areas deep inside the pump, they get squeezed hard and burst rapidly, creating multitudes of shock waves, grinding noise, and vibration so intense it sounds as though gravel, not steam bubbles, are passing through the pump. The noise and vibration are bad enough, but cavitation has far worse consequences.

Rapidly imploding bubbles form tiny but powerful micro jets of water which hold an enormous amount of kinetic energy. When these jets hit the pump’s metal interior, their kinetic energy causes minute fragments of metal to break away. Over time these tiny water jets wear away enough metal to cause damage to the pump’s interior and interfere with function.

Next time we’ll see how cavitation bubbles flowing through the low pressure area of a pump degrade its performance.

opyright 2018 – Philip J. O’Keefe, PE

Engineering Expert Witness Blog

____________________________________ |

Tags: cavitation, cavitation bubbles imploding, centrifugal pump, micro jet, noise, pump high pressure area, pump low pressure area, shock waves, vibration

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, power plant training, Product Liability | Comments Off on Rapidly Imploding Bubbles Create Problems