| Have you ever come home to a basement full of water? The sinking feeling in your stomach at the moment of discovery is soon followed by a cascade of other emotions: fear, anger, and you probably had a few choice sailor’s words to round off the experience.

What’s just happened? Well, it may very well have been a water heater explosion, and the water on the floor may be just the beginning of the damage. Perhaps you even have a hole blown into the side of your house! Watch this video for excellent graphic footage of just such an explosion: You probably didn’t realize that the water heater in your home has the potential to become a pressure vessel, and with that present all of the potential dangers that a pressure vessel presents. Remember our discussion on the Boyle-Charles Law a few weeks ago? We learned that in the fixed volume environment of a pressurized container if the temperature keeps climbing, the pressure keeps building, and the outcome of this coupling is precisely what we’re observing in the video. The water in the water heater has turned to steam, causing pressure to build in the vessel until rupture occurs. None of us wants to come home to a basement filled with water, much less a hole blown through our house by a rocketing water heater, so how can we prevent it from happening? One answer is to have your water heater regularly serviced by a qualified plumber. The plumber would make sure that the overpressure device on the water heater tank, namely the relief valve (a.k.a. T&P valve), is in proper working order. Now you may have noticed a circle drawn around the water heater’s relief valve in the video. As their name implies, relief valves are used to relieve pressure buildup, generally of liquids. If the pressure within the water heater reaches a certain limit, set by the heater’s manufacturer, the relief valve will automatically open to vent off the pressure. A pipe on the outlet of the valve safely directs the water and steam that is let off to the floor where it can flow down to a drain. That’s why floor drains are usually located in close proximity to water heaters. Besides relief valves, overpressure devices come in many configurations, including: safety valves, rupture discs, fusible plugs, and temperature limiting controls. They may be used singly or jointly in order to perform the same basic function, that is, to keep the pressure within a vessel from building to the point where it may fail. Next week we’ll explore the other overpressure devices mentioned and where they are generally employed. _____________________________________________ |

Posts Tagged ‘Boyle-Charles Law’

Pressurized Containers – Overpressure Devices

Sunday, October 10th, 2010Pressurized Containers

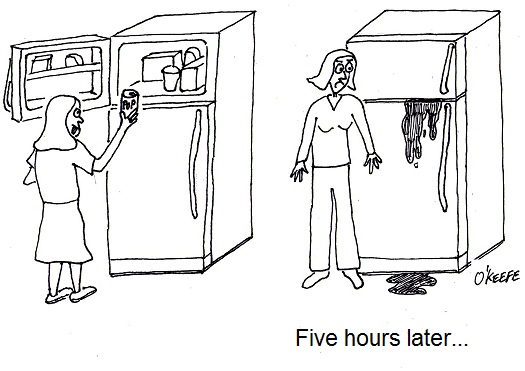

Sunday, September 19th, 2010| My dear daughter is at times forgetful? On one occasion in particular she forgot that she had placed a can of pop in the freezer to speed-chill it. Later that evening when my wife went to get something out of the freezer she was not too pleasantly surprised to find that a black, semi-solid mess had covered most of the freezer’s interior. You got it. The pop can exploded, shooting its pressurized contents all over the place.

You may not have thought much about it before, but pressurized containers are all around us, from pop to aerosol cans, car tires, water heaters, and liquid petroleum gas tanks. Pressurized containers are even more obvious in industrial settings such as oil refineries, power plants, and factories. As its name would imply, pressurized containers, or pressure vessels, are under a lot of pressure, as such, they are no stronger than their weakest point. Whether that point be its sides, as in the case of my daughter’s ruptured pop can, or its ends, weld joints, rivets, or any of the other components that are included in the vessel’s construction. As with anything, the integrity of something is only as good as its weakest part. In an industrial setting, this fact, depending on the vessel’s contents and the severity of the failure, can prove deadly. So what causes pressure in a vessel to get too high? Many factors could be at play, from a safety valve which fails to do its job of relieving excess pressure, to absence of this feature entirely. Many of us learned in grade school science class that when a substance heats up, its molecules vibrate, causing its atoms to want to distance themselves from each other. If this vibrating is taking place within a closed vessel, heated atoms will be prevented from carrying out their desired separation. The result is pressure increases, and along with it the propensity for the weakest points to fail. Whether it’s a slow ooze, high spirited fizz, or outright explosion, the end result is generally the same – it’s a big mess. The behavior of gases in pressurized vessels exposed to heat can be summed up by the Boyle-Charles Law, named after the 17th Century scientist, Robert Boyle, and a 19th Century scientist named Jacques Charles. Both were pioneers in their study of how gases behave under various conditions. The science behind their observations can be summarized into a neat little formula, known as the Boyle-Charles Law for sealed pressure vessels. It looks like this: P1÷T1 = P2÷T2 where P is absolute pressure and T is absolute temperature. What is absolute pressure? It’s the pressure that’s measured when you add the pressure of the air that we live in, our atmosphere, which has been measured to be 14.7 PSI, or pounds per square inch, to whatever pressure you are reading on a pressure gauge. This ultimate pressure is measured at pounds per square inch absolute, or PSIA. Now what is meant by absolute temperature is calculated a little differently. It basically means that you add 460 degrees to the temperature reading on a thermometer. This 460 degrees acts as a kind of fudge factor to keep equations that concern themselves with temperature at or below 0°F to work. The result is said to be in degrees Rankine, and it is denoted by °R. So why do we need this fudge factor? Here’s an example. In the equation above, if temperature is 0°F, then you would be dividing the pressure by zero in the equation above. That’s a no-no in mathematics. Try dividing any number by zero on your calculator and see what I mean. Okay, for those of you who are not mathematically inclined that may not have been very clear. Let’s try a different approach. Probably the best way to show you how the Boyle-Charles Law works is by the following example. Suppose you have a sealed container filled with pressurized gas. The gas is at a temperature of 70°F, and a pressure gauge on the vessel reads 100 PSI. So this condition of pressure and temperature goes into the Boyle-Charles Law equation as P1 = (100 PSI + 14.7 PSI) = 114.7 PSIA and T1 = (70°F + 460) = 530°R. Now let’s introduce a complicating factor. Suppose you leave the container in your car on a hot day. The gas in the container increases in temperature to 150°F. Okay, so this temperature would go into the Boyle-Charles Law equation as T2 = (150°F + 460) = 610°R. Now, suppose the pressure gauge was damaged and the needle fell off. What would the gas pressure in the container be at this temperature? Let’s use the Boyle-Charles Law equation and a little algebra to find out: P1÷T1 = P2÷T2 114.7 PSIA ÷ 530°R = P2÷ 610°R P2 = (114.7 PSIA ÷ 530°R) × 610°R P2 = 132 PSIA = 117.3 PSI What this means is that if the weakest link in a container was made to withstand no more than 110 PSI of pressure, and the pressure inside the vessel in our case has risen to 117.3 PSI, the integrity of our container will be compromised. We’ll return to our vehicle and find a big mess. We’ll continue our discussion of pressure vessels, leaks, and how they can be prevented in the future. _____________________________________________ |