|

Hold onto your hats, we’re going to deal with a lot of equations today! Last time we used flashbacks to previous blogs in this series to revisit key equations in our ongoing discussion of gear trains and torque. We also introduced The Law of Conservation of Energy in conjunction with five equations that together demonstrate how when increasing torque by use of a simple gear train, we do so at the cost of speed. Those five equations are:

where, R is the gear ratio, N the number of gear teeth, n the gear’s rotational speed, T the torque, D the gear pitch radius, and HP is the horsepower transmitted by the gears. As we work the equations, keep in mind that our ultimate objective is to find a way to link together (1) and (2), the equations dealing with gear torque and speed. Once we accomplish this we’ll see how increased torque is obtained at the cost of speed. But because there are no common terms between equations (1) and (2), our first step is to develop one. Developing a link between equations (1) and (2) is a process that begins with combining equations (2), (3), and (4).

The common terms in these three equations are TDriving and TDriven, so we’ll manipulate things in order to group them together. We’ll substitute equation (3) for the TDriving term in equation (2), and substitute equation (4) for the TDriven term in equation (2). We are now able to link all three equations to get: {[HPDriving ÷ nDriving] × 63,025} ÷ {[HPDriven ÷ nDriven] × 63,025} = DDriving ÷ DDriven (6) Now let’s go a step further to simplify equation (6). From equation (5) we know that the driving and driven gear horsepowers are equal. So, in equation (6), the HPDriving and HPDriven cancel out, along with the two 63,025 terms, allowing us to arrive at equation (7): {[HPDriving ÷ nDriving] × 63,025} ÷ {[HPDriven ÷ nDriven] × 63,025} = DDriving ÷ DDriven

Next week we’ll use equation (7) to link together R, N, n, of equation (1) with D and T of equation (2) and in so doing disclose mathematically the tradeoff between torque and speed, then apply our findings to an example. _______________________________________

|

Posts Tagged ‘mechanical engineer expert witness’

Determining the Gear Train Tradeoff of Torque vs. Speed, Part One

Friday, August 15th, 2014Mechanical Engineering, Not Just About Gears

Sunday, October 11th, 2009|

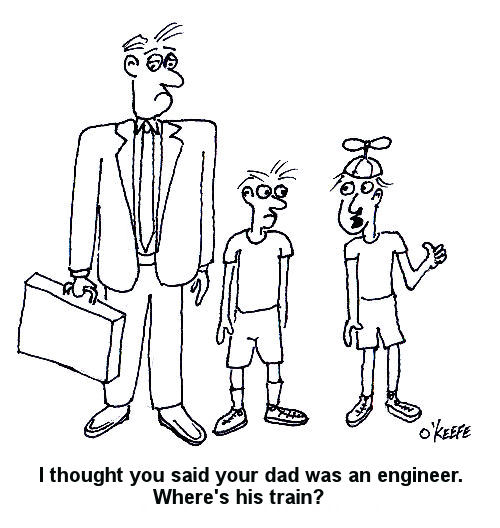

When I was a kid I had a friend who thought that everyone who said they were an engineer wore pinstriped bib overalls and drove trains. Funny thing is, I later became both a locomotive engineer and a degreed mechanical engineer, but that’s a story for another time. Speaking of engineers, what do you think of when you hear the words, “mechanical engineer?” If you’re like most, you probably think of someone who designs gears and machinery. But the field of mechanical engineering is far more complex than that. Mechanical engineering is one of the oldest and broadest of engineering disciplines. It encompasses a broad number of disciplines, from physics to materials science, but it can be summarized as being derived from ten core areas:

Armed with this knowledge, mechanical engineers can take on design projects ranging from airplane propellers to utility power plants. During the coming weeks we will focus on each of these areas and explore them more fully. We may even have a little quiz at the end to test your newfound knowledge! Our first topic will be: Statics, the study of how forces are transmitted to and throughout stationary objects. And here is a riddle to get you started in your personal exploration of the subject matter: Everyone knows us when they look at a clock, but mechanical engineers also know us to add up to zero when they look at a fixed structure. What are we? Get the answer in my next blog post. _________________________________________________________________ |