| My wife often says I’m the worst cook she knows. This doesn’t really bother me too much, because she’s the best cook I know, and she keeps me well fed. But there are times that I have to fend for myself in the kitchen, and this sometimes results in a foul smelling mess plastered all over the stove. Lucky for me we have a nice exhaust hood, and it usually manages to suck out the odor before my wife gets home.

Local exhaust ventilation systems, like the vent over my stove, work much the same way in an industrial setting, albeit on a larger scale. This type of ventilation system gets its name because its action is quite specific, localized to contain exhaust air from a particular area. They’re routinely placed as close as possible to the source of contaminants, and they are able to work quickly to capture and expel chemical vapors, dusts, and fumes, before they spread. This type of ventilation is effective for other reasons, too, because it helps keep down heating and cooling costs. Instead of treating an entire building for ventilation issues, the problem can be nipped in the bud at its source. In many situations, local exhaust ventilation is preferred over dilution ventilation systems for these very reasons. A basic local exhaust ventilation system is comprised of a duct, a fan, and a hood as shown in Figure 1 below. One end of the duct is attached to the intake of the fan. The other end of the duct is attached to the hood. The duct can be rigid or flexible. The hood is positioned in the workplace near the source of contaminants. Figure 1 – Basic Local Exhaust Ventilation System This local exhaust ventilation system operates by much the same principle as the one generally governing the movement of liquids and gases. If you’re a regular reader of this blog, you’ll remember me writing that liquids and gases always flow from areas of higher pressure to those of lower pressure. Well, the air within the room has pressure principles at play as well, and the air within a given work area is at atmospheric pressure. When the fan is introduced into the scenario, a vortex is created within the duct which is less than that of the atmospheric pressure in the room. This difference in pressures causes the room air to flow into the ventilation duct along with its contaminants. The room air and contaminants flow out through the ventilation system, where they are then exhausted outside of the building. But because room air is being drawn into the ventilation system, provisions must be made to supply enough replacement air. Without the proper ratio of air moving in to that moving out, a ventilation system will not work properly. In other words, the suction created by the local ventilation system could cause the pressure in the room to drop below atmospheric pressure. This could cause the higher atmospheric pressure outside the room to bear down on doors, making them difficult to open. Worse yet, contaminants could back up into the room, causing workers to get sick. Now that we’ve covered the basics of local exhaust ventilation, we can move on to its five constituent elements and a discussion of their design. We’ll do that next week. _____________________________________________ |

Posts Tagged ‘HVAC’

Industrial Ventilation – Local Exhaust Ventilation

Sunday, April 10th, 2011Industrial Ventilation – Dilution Ventilation

Sunday, April 3rd, 2011| If you’re a fan of the new hit HBO series, Boardwalk Empire, then you know a lot about the effects of Prohibition. But did you know that Prohibition is responsible for the creation of mixed drinks? Until then, people drank their liquor straight. Then along came Prohibition, mob rule, and the desire to keep the booze, including some with questionable origins, flowing. This booze didn’t taste so good, and the addition of a sugary beverage to it, that is, diluting it with soda or juice, made it a lot easier to go down. By the time Prohibition was repealed in 1933, the mixed drink had taken a firm foothold in American society.

Most adults are aware of the fact that liquor, in excess, is toxic to the body. Too much of it, and the liver, which acts as a filtration device, itself becomes toxic. When that happens, poor health will follow. The same principle applies to air within a building. If it becomes thick with toxic fumes or potentially flammable vapors, indoor air quality will suffer. But if you infuse fresh air into the environment, the toxic load is diluted, making the environment habitable and safe. This addition of fresh air is called, appropriately enough, dilution ventilation. Now, the easiest way to create a dilution ventilation system is to open a window. Trouble is there often isn’t enough natural airflow to do much good. But if you step up the effort by introducing a mechanical ventilation system, complete with blowers and ductwork, the need to crack open a window becomes obsolete. By exchanging bad air for good and introducing a continual flow of fresh air, toxicity is diluted and its effects are minimized, much like the bathtub gin of Prohibition was improved by the addition of soda. The chance of fire or explosion is reduced as well. There are however limits to what dilution ventilation can accomplish. If contaminants are highly toxic or extremely flammable, then this type of ventilation system is not going to do much good. This is a situation where extremely high air flows would be required, and this is often impractical both from a cost and comfort standpoint. Imagine having to work inside a wind tunnel? In situations like these a local exhaust ventilation system is better suited to do the job, and we’ll see how those work next week. _____________________________________________ |

Industrial Ventilation

Sunday, March 27th, 2011| On a hot, sticky day, what price would you pay for a cool breeze? Imagine for a moment that it’s 90 degrees in the shade and humidity is 85%. There are few human beings that wouldn’t consider this uncomfortable weather, although I have some die hard neighbors who rarely close their windows during the summer to engage the air conditioning, a rather recent modern convenience. My mom told me stories of how it was common in the 1940s for entire Chicago neighborhoods to head to Lake Michigan, spread a blanket, and sleep on the beach to keep cool on the hottest nights. As for myself, I remember being really happy when Dad broke down and finally purchased a window air unit. It was as big as a small refrigerator and took two men to lift. It was loud and drew so much power it frequently “blew the fuse.” It was so much nicer when central air conditioning came along a few years later and we could finally retire that old clunker.

Ultimately, it’s ventilation that makes air conditioning work, the principle here being a continuous circulation of air, exchanging hot for cooled. If you’ll remember, hot air gives up its heat to coils containing coolant, and the newly cooled air is released back into the room. In addition to cooling, another major function of ventilation is to remove odors and refresh the air. Everyone likes a fresh smelling home, but even more importantly, proper ventilation reduces the concentration of contaminants in the air, things which tend to make us sick, like mold. That’s why many states’ building codes require whole house air ventilation systems to be installed in new homes. In industrial settings ventilation performs the same functions, but it’s necessary for other reasons as well. Industrial facilities often house processes that create airborne toxins and other contaminants. These byproducts of manufacturing can be dangerous if allowed to collect unchecked within the confines of a building. Air containing certain concentrations of contaminants, such as vapors emitted by paints and solvents, can ignite, resulting in fire or explosion. For safety of both workers and equipment, fresh air must displace air contaminated with fumes and dust. There are three types of ventilation that can be found in industrial facilities. These include indoor air quality ventilation, dilution ventilation, and local exhaust ventilation. Indoor air quality ventilation provides freshly heated or cooled air to buildings as part of the normal heating, ventilating and air conditioning system, much like we have in our own homes. Dilution ventilation gets its name from the fact that it dilutes contaminated air by displacement, the blowing in of clean air and exhausting of dirty. The last type of ventilation, local exhaust ventilation, captures contaminated emissions at or near the source and exhausts them directly outside. Depending on the type of industrial application one, two, or all three of these ventilation types may be employed to keep air quality safe. Next week we’ll discuss dilution ventilation in detail, followed by local exhaust ventilation, and we’ll gain a better understanding of how they are used to protect worker health and safeguard property. _____________________________________________ |

Thermodynamics In Mechanical Engineering, Part III, Refrigeration Cycles

Sunday, December 20th, 2009|

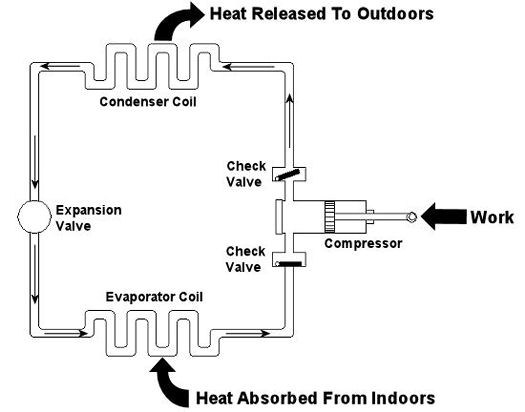

Last week we talked about an area of thermodynamics that concerns power cycles, an example of which can be found in a coal fired power plant. This week we’ll learn about another area of thermodynamics, that of refrigeration cycles. It’s been snowing in the Midwest, so the topic seems appropriate enough. A refrigeration cycle is obviously found in your refrigerator, but did you know that it’s also found in your air conditioner? Refrigeration cycles operate in Opposite Land as compared to power cycles. You know, the place where everything works in reverse. Instead of heat going into the cycle and electricity coming out, in a refrigeration cycle, electricity goes in and heat comes out—out of your refrigerator or air conditioned house, that is. Let’s consider an example of the simple air conditioner refrigeration cycle shown in Figure 1. The cycle has four important parts: an evaporator coil, a compressor, a condenser coil, and an expansion valve. All parts are connected by pipes, and the entire system is sealed up tight with refrigerant inside. Figure 1 – A Simple Refrigeration Cycle Used In An Air Conditioner The compressor is the heart of the operation, so to speak. In our simple cycle, the compressor consists of an electric motor-driven piston that moves back and forth within a cylinder. The motor does work as the piston moves back and forth, and the compressor pumps refrigerant through the pipes, the condenser coil, the expansion valve, and the evaporator coil. Like your heart, the pump has check valves that keep refrigerant flowing through the system in one direction (counterclockwise in our example). Keeping the flow going in one direction is critical to the operation of the cycle, as we’ll see in a moment. The refrigerant is the life blood of the cycle. It is a chemical that is manufactured to have special thermodynamic properties. For example, it’s really good at quickly absorbing a lot of heat at low temperature, like the temperature of the air in your house. The evaporator coil in Figure 1 would be located on the inside of your home. As the refrigerant enters the evaporator coil, it is a mixture of liquid and vapor. Inside the evaporator coil, the liquid refrigerant boils off to a vapor as it absorbs heat from the room. Yes, that’s right, the refrigerant boils at room temperature! The heat absorption in the evaporator is helped along by using a fan to push room air across its coil. Warm air from the room gets sucked into the air conditioner and cool air blows out into the room. But that’s not the end of the story. That heat from the room has to somehow get outside of the house, where it can be disposed of. This is so the refrigerant can pick up another load of heat when it flows back through the evaporator coil. But disposing of the heat from the refrigerant isn’t easy, since heat naturally wants to flow from a hotter place to a cooler place. So how do you buck Mother Nature and get heat to flow from the inside of your house where it’s cool to the outside of your house where it’s hotter? It takes work, and that’s where the compressor comes into play. The compressor first pulls the refrigerant vapor out of the evaporator and raises its pressure and temperature. This heart, like our own, is a hard worker. As the vapor leaves the compressor and passes through the condenser coil located outside your home, it is in a state where it can easily give up its heat to the warm air outside. The release of heat is helped along by the use of another fan that serves to push the outdoor air across the outside surfaces of the condenser coil. Then, as heat is released to the outdoor air, the refrigerant condenses back into a liquid. After leaving the condenser coil, the liquid refrigerant passes through the expansion valve, where its pressure and temperature are reduced. The refrigerant is now ready to pick up a new load of heat in the evaporator coil, and the cycle repeats itself with the help of a working electric motor. Next week, we’ll continue our exploration of thermodynamics and narrow our focus onto an area known as stoichiometry, which is concerned with the math behind chemical reactions, like those that take place during the burning of fuels. Math is fun. Just keep repeating that to yourself. _________________________________________________________________ |