|

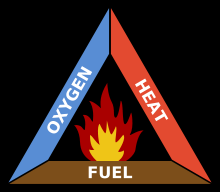

Property damage and loss of lives, these are often the result of fires. But did you know that one of the leading causes of fire is electricity? Residential electrical fires claim the lives of nearly 500 Americans each year and injure another 2300. Annually, these fires result in over $800 million in property losses. Approximately one third of the nearly 70,000 home electrical fires that occur each year are traceable to design and manufacturing defects in electrical products. The rest are caused by the misuse and poor maintenance of electrical products, overloaded circuits and extension cords, and incorrectly installed wiring. The three components that must be present in order for a fire to manifest and sustain itself are well known. These components make up the “Fire Triangle,” a potentially lethal combination of heat, fuel, and oxygen. If any one of these three components is missing from the triangle, a fire can’t be started or sustained. In the case of an electrical fire, it’s electricity that creates the heat component of the Fire Triangle.

The Fire Triangle How does electricity contribute to fires? One example would be an overloaded extension cord. Homeowners are sometimes unaware that extension cords must be sized appropriately for their ultimate usage. If not, they can overheat, particularly if they are damaged. Damage to cords can result from a myriad of factors, from factory production errors to kinking when heavy furniture is carelessly placed on top of them. The same principle holds true for electrical products. If their internal wiring or a component is insufficiently sized or damaged, overheating can result. If things get hot enough and there is sufficient airflow (oxygen) and combustible material (fuel) in the vicinity, then the fire triangle is complete. The fire starts internally and can soon spread to other objects in the area. Electrical arcing can occur when an energized electrical circuit is broken. For example, suppose a wire carrying current is suddenly broken in two. If the voltage is high enough, the electricity will want to continue to flow through the air across the break to form an electrical arc. If the power flowing through the arc is great enough, heat can once again complete the Fire Triangle, resulting in fire. Forensic engineering analysis of evidence collected from a fire scene often yields telltale signs of overheating due to overloaded electrical circuits or damaged wiring in components. Under close examination by an experienced professional, even the smallest strand of wire can point to the cause of an electrical fire. CSI skills aren’t only employed at crime scenes. Forensic engineers also use similar techniques to get to the true story of cause and effect. _________________________________________________________________ |

Engineering Expert Witness Blog

Published by Philip J. O'Keefe, PE, MLE