| Last week our kitchen ceiling fan and light combo decided to stop working. We don’t like eating in the dark, so I was compelled to do some immediate troubleshooting. As an engineer with training in the workings of electricity I have a great respect for it. I’m well aware of potential hazards, and I took a necessary precaution before taking things apart and disconnecting wires. I made the long haul down the stairs to the basement, opened the circuit breaker in the electrical panel, and disabled the flow of electricity to the kitchen. My fears of potential electrocution having been eliminated, my only remaining fear was of tumbling off the ladder while servicing the fan.

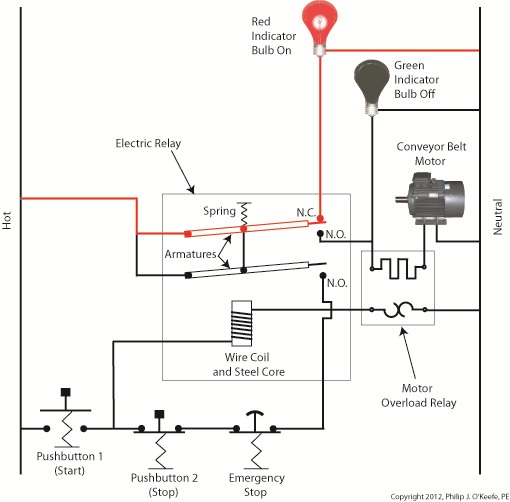

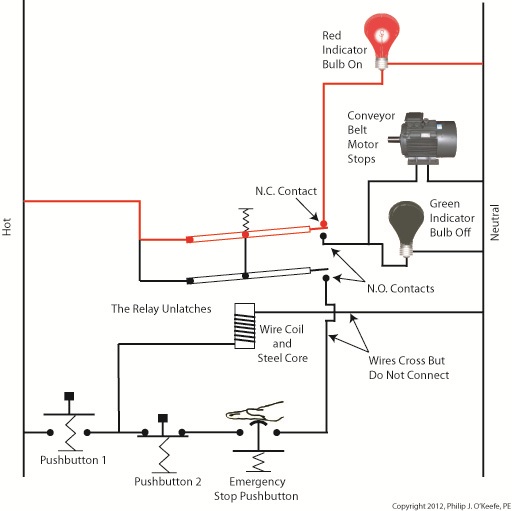

Just as I took the precaution to disconnect the power supply before performing electrical maintenance in my home, workers in industrial settings must do the same, and a chief player in those scenarios is the motor overload relay discussed last week. It automatically shuts down electric motors when they become overheated. Let’s revisit that example now. Figure 1

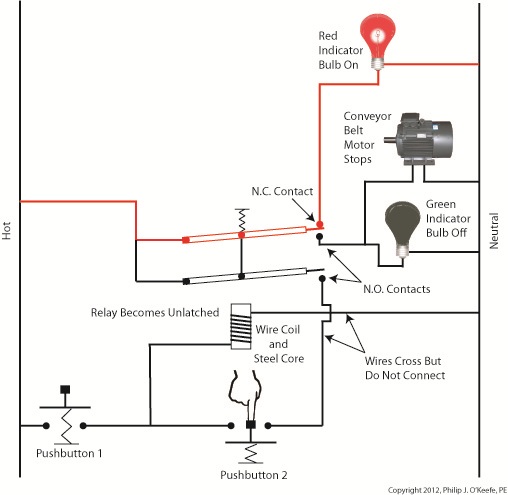

Our diagram in Figure 1 shows electric current flowing through the circuit by way of the red path. Even if this line were shut down, current would continue to flow along the path, because there is no means to disconnect the entire control system from the hot and neutral lines supplying power to it, that is, it is missing disconnect switches. Electric current will continue to pose a threat to workers were they to attempt a repair to the system. Now let’s see how we can eliminate potential hazards on the line. Figure 2

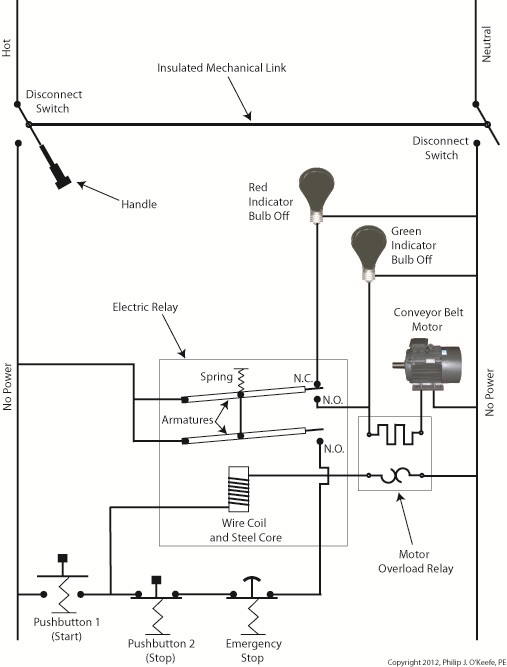

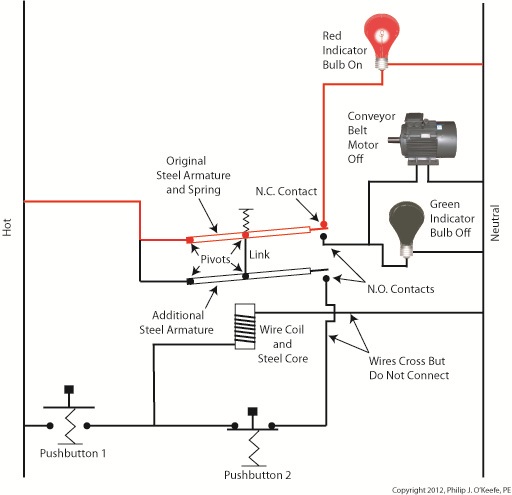

In Figure 2 there is an obvious absence of the color red, indicating the lack of current within the system. We accomplished this with the addition of disconnect switches capable of isolating the motor control circuitry, thereby cutting off the hot and neutral lines of the electrical power supply and along with it the unencumbered flow of electricity. These switches are basically the same as those seen in earlier diagrams in our series on industrial controls, the difference here is that the two switches are tied together by an insulated mechanical link. This link causes them to open and close at the same time. The switches are opened and closed manually via a handle. When the disconnect switches are both open electricity can’t flow and nothing can operate. Under these conditions there is no risk of a worker coming along and accidentally starting the conveyor motor. To add yet another level of safety, disconnect switches are often tagged and locked once de-energized. This prevents workers from mistakenly closing them and starting the conveyor while maintenance is being performed. Brightly colored tags alert everyone that maintenance is taking place and the switches must not be closed. The lock that performs this safety function is actually a padlock. It’s inserted through a hole in the switch handle, making it impossible for anyone to flip the switch. Tags and locks are usually placed on switches by maintenance personnel before repairs begin and are removed when work is completed. Now let’s see how our example control system looks in ladder diagram format. Figure 3

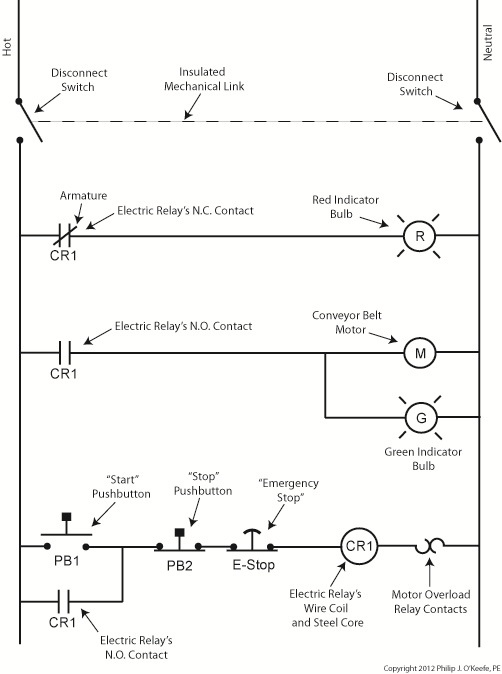

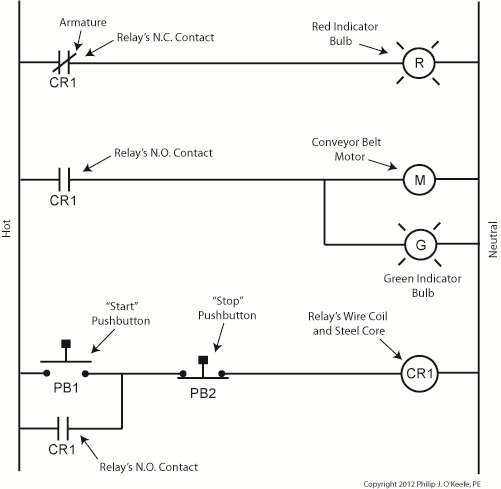

Figure 3 shows a ladder diagram that includes disconnect switches, an emergency stop button, and the motor overload relay contacts. The insulated mechanical link between the two switches is represented by a dashed line. Oddly enough, engineering convention has it that the motor overload relay heater is typically not shown in a ladder diagram, therefore it is not represented here. This wraps up our series on industrial control. Next time we’ll begin a discussion on mechanical clutches and how they’re used to transmit power from gasoline engines to tools like chainsaws and grass trimmers. ____________________________________________

|

Posts Tagged ‘control panel’

Industrial Control Basics – Disconnect Switches

Sunday, March 25th, 2012Tags: chainsaw, circuit breaker, circuitry, clutch, control panel, conveyor belt, current flow, death, disconnect switch, electric motor, electric relay, electrical maintenance, electrical panel, electricity, electrocution, emergency stop, engineering expert witness, forensic engineer, hot, indicator bulbs, industrial control system, injury, lawn trimmer, lock, lockout tag out, maintenance worker, motor overheated, neutral, overload relay, overload relay heater, potential hazards, power supply, pushbutton, safety, safety hazard, tag, troubleshooting, wires

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability, Professional Malpractice | Comments Off on Industrial Control Basics – Disconnect Switches

Industrial Control Basics – Emergency Stops

Sunday, February 26th, 2012| Ever been in the basement when you heard a loud thud followed by a scream by a family member upstairs? You run up the stairs to see what manner of calamity has happened, the climb seeming to take an eternity. Imagine a similar scenario taking place in an industrial setting, where distances to be covered are potentially far greater and the dangerous scenarios numerous.

Suppose an employee working near a conveyor system notices that a coworker’s gotten caught in the mechanism. The conveyor has to be shut down fast, but the button to stop the line is located far away in the central control room. This is when emergency stop buttons come to the rescue, like the colorful example shown in Figure 1. Figure 1

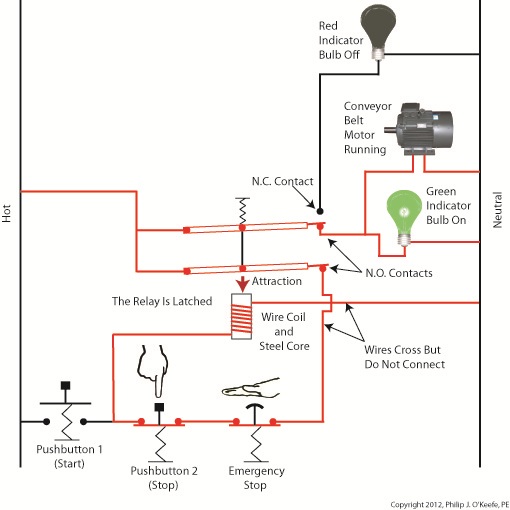

Emergency stop buttons are mounted near potentially dangerous equipment in industrial settings, allowing workers in the area to quickly de-energize equipment should a dangerous situation arise. These buttons are typically much larger than your standard operational button, and they tend to be very brightly colored, making them stick out like a sore thumb. This type of notoriety is desirable when a high stress situation requiring immediate attention takes place. They’re easy to spot, and their shape makes them easy to activate with the smack of a nearby hand, broom, or whatever else is convenient. Figure 2 shows how an emergency stop button can be incorporated into a typical motor control circuit such as the one we’ve been working with in previous articles. Figure 2

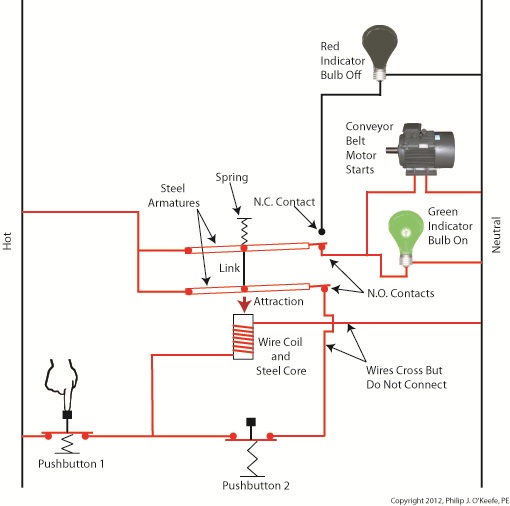

An emergency stop button has been incorporated into the circuit in Figure 2. It depicts what happens when someone depresses Button 1 on the conveyor control panel. The N.C. contact opens, and the two N.O. contacts close. The motor starts, and the lit green bulb indicates it is running. The electric relay is latched because its wire coil remains energized through one N.O. contact. It will only become unlatched when the flow of current is interrupted to the wire coil, as is outlined in the following paragraph. The red lines denote areas with current flowing through them. Both Button 2 and the emergency stop button typically reside in normally closed positions. As such electricity will flow through them on a continuous basis, so long as neither one of them is re-engaged. If either of them becomes engaged, the same outcome will result, an interruption in current on the line. The relay wire coil will then become de-energized and the N.O. contacts will stay open, preventing the wire coil from becoming energized again after Button 2 or the emergency stop are disengaged. Under these conditions the conveyor motor stops, the green indicator bulb goes dark, the N.C. contact closes, and the red light comes on, indicating that the motor is not running. This sequence, as it results from hitting the emergency stop button, is illustrated in Figure 3. Figure 3

We now have the means to manually control the conveyor from a convenient, at-the-site-of-occurrence location, which allows for a quick shut down of operations should the need arise. So what if something else happens, like the conveyor motor overheats and catches on fire and no one is around to notice and hit the emergency stop? Unfortunately, in our circuit as illustrated thus far the line will continue to operate and the motor will continue to run unless we incorporate an additional safeguard, the motor overload relay. We’ll see how that’s done next time. ____________________________________________ |

Tags: control panel, control room, conveyor, de-energize equipment, electric relay, emergency pushbutton, emergency stop button, engineering expert witness, equipment shut down, fire, forensic engineer, hot, indicator bulb, industrial control, ladder diagram, latched relay, motor control, motor control circuit, motor overheat, N.C. contact, N.O. contact, NC contact, neutral, NO contact, overload relay, push button, pushbutton, relay armature, relay coil, relay ladder logic, safeguard, unlatched relay

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability, Professional Malpractice | 2 Comments »

Industrial Control Basics – Electric Motor Control

Sunday, February 19th, 2012| Electric motors are everywhere, from driving the conveyor belts, tools, and machines found in factories, to putting our household appliances in motion. The first electric motors appeared in the 1820s. They were little more than lab experiments and curiosities then, as their useful potential had not yet been discovered. The first commercially successful electric motors didn’t appear until the early 1870s, and they could be found driving industrial devices such as pumps, blowers, and conveyor belts.

In our last blog we learned how a latched electric relay was unlatched at the push of a button, using red and green light bulbs to illustrate the control circuit. Now let’s see in Figure 1 how that circuit can be modified to include the control of an electric motor that drives, say, a conveyor belt inside a factory. Figure 1

Again, red lines in the diagram indicate parts of the circuit where electrical current is flowing. The relay is in its normal state, as discussed in a previous article, so the N.O. contacts are open and the N.C. contact is closed. No electric current can flow through the conveyor motor in this state, so it isn’t operating. Our green indicator bulb also does not operate because it is part of this circuit. However current does flow through the red indicator bulb via the closed N.C. contact, causing the red bulb to light. The red and green bulbs are particularly useful as indicators of the action taking place in the electric relay circuit. They’re located in the conveyor control panel along with Buttons 1 and 2, and together they keep the conveyor belt operator informed as to what’s taking place on the line, such as, is the belt running or stopped? When the red bulb is lit the operator can tell at a glance that the conveyor is stopped. When the green bulb is lit the conveyor is running. So why not just take a look at the belt itself to see what’s happening? Sometimes that just isn’t possible. Control panels are often located in central control rooms within large factories, which makes it more efficient for operators to monitor and control all operating equipment from one place. When this is the case, the bulbs act as beacons of the activity taking place on the line. Now, let’s go to Figure 2 to see what happens when Button 1 is pushed. Figure 2

The relay’s wire coil becomes energized, causing the relay armatures to move. The N.C. contact opens and the N.O. contacts close, making the red indicator bulb go dark, the green indicator bulb to light, and the conveyor belt motor to start. With these conditions in place the conveyor belt starts up. Now, let’s look at Figure 3 to see what happens when we release Button 1. Figure 3

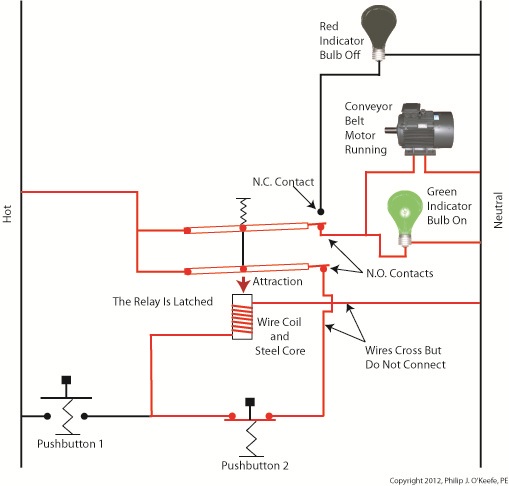

With Button 1 released the relay is said to be “latched” because current will continue to flow through the wire coil via one of the closed N.O. contacts. In this condition the red bulb remains unlit, the green bulb lit, and the conveyor motor continues to run without further human interaction. Now, let’s go to Figure 4 to see how we can stop the motor. Figure 4

When Button 2 is depressed current flow through the relay coil interrupted. The relay is said to be unlatched and it returns to its normal state where both N.O. contacts are open. With these conditions in place the conveyor motor stops, and the green indicator bulb goes dark, while the N.C. contact closes and the red indicator bulb lights. Since the relay is unlatched and current no longer flows through its wire coil, the motor remains stopped even after releasing Button 2. At this point we have a return to the conditions first presented in Figure 1. The ladder diagram shown in Figure 5 represents this circuit. Figure 5

Next time we’ll introduce safety elements to our circuit by introducing emergency buttons and motor overload switches. ____________________________________________ |

Tags: blower, closed contact, control panel, control room, conveyor belt, electric current flow, electric motor, electric relay, engineering expert witness, equipment operator, factory, forensic engineer, indicator lamp, industrial control, ladder diagram, latched circuit, motor control, motor drive, N.C., N.O., normal state, normally closed, normally open, panel indicator, pump, push button, safety, start pushbutton, stop pushbutton

Posted in Engineering and Science, Expert Witness, Forensic Engineering, Innovation and Intellectual Property, Personal Injury, Product Liability, Professional Malpractice | Comments Off on Industrial Control Basics – Electric Motor Control