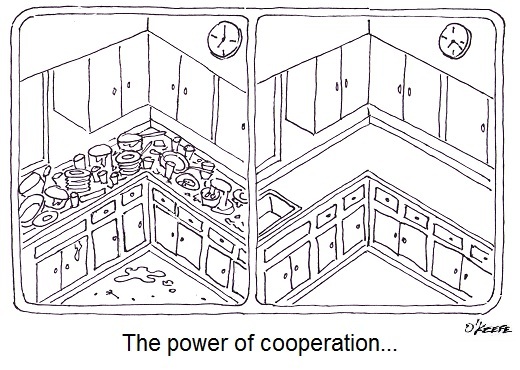

| My daughter’s boy friend stayed for dinner recently and was impressed with our after-dinner cleanup. He watched as each of us carried out our individual assigned tasks, my wife putting away leftovers and condiments, my daughter rinsing and stacking plates into the dishwasher, and me at the sink hand washing. To him we seemed a model of efficiency. It didn’t take long to return the kitchen to its usual state of pristine evening cleanliness. “Our kitchen is always a mess,” he complained, “probably because we’re so disorganized.”

You can imagine what would happen if a food manufacturing plant operated like a disorganized household kitchen. Although employees may know they are responsible for delivering safe products to consumers, without the right procedures in place an unsafe chaotic mess may result. To get everyone moving in the right direction we look to guidelines established in HACCP Design Principle No. 6. Principle 6: Establish procedures for ensuring the HACCP system is working as intended. – In large part this Principle acts as a report card. It follows up on the guidelines established in Principles l through 5, organizing activities into written procedures. For example, design engineers must routinely analyze important identified stages within a design project, then write procedures, that is, a step-by-step instruction guide, which encompasses them. In this way personnel involved in the design process make best use of the safeguards put in place by HACCP Design Principles 1 through 5. These steps include things like preparing design proposals, analyzing risks and hazards, creating preliminary designs, conducting design reviews, building prototype equipment and tooling, running tests, collecting test data, and analyzing test results. For each step, responsibilities of key individuals involved must be clearly defined and sequentially ordered. But writing department procedures is only part of Principle 6. Procedures are no good if they’re just thrown into a file cabinet and no one ever looks at them. What good are guidelines without a full understanding of how to use them? Training may be necessary, and management must decide what form that educational process takes to be most effective. Engineering management must verify that established procedures are adequate to the task. This typically involves taking a hard look at finished design projects and checking critical factors. Was an adequate risk analysis performed? Were sufficient critical control points established and critical limits monitored for effectiveness? Next time we’ll wrap up our discussion on HACCP Design Principles by examining No. 7. It’s the last of the Principles and it’s concerned with establishing record keeping procedures. ____________________________________________

|

Posts Tagged ‘food safety’

Food Manufacturing Challenges – HACCP Design Principle No. 6

Sunday, November 20th, 2011Food Manufacturing Challenges – HACCP Design Principle No. 5

Saturday, November 12th, 2011| Picture yourself on a highway, it’s dark out, the wind is blowing fiercely, and you’re unable to see that the pavement is accumulating icy patches. You hit one, and your car veers out of control. Luckily you drive one of the new generation of “smart” vehicles. Wheel sensors detect your predicament and immediately initiate a sequence of events to correct the situation and bring your vehicle back into control.

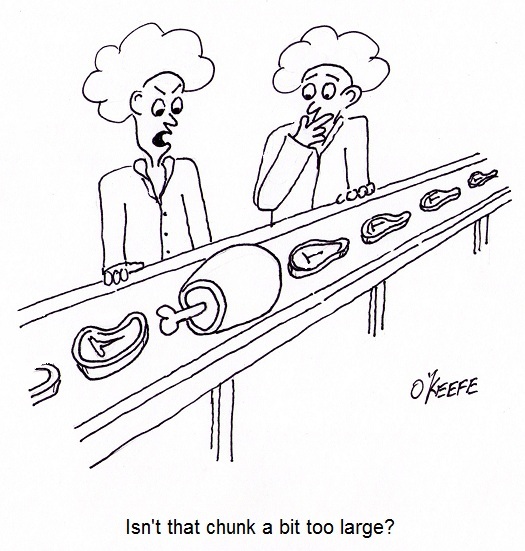

Corrective measures need to be taken in many situations when things go awry, whether they be computer-generated or human-generated corrections, and food manufacturing facilities are not exempt from the process. Let’s look at how this applies within HACCP Design Principle No. 5. Principle 5: Establish corrective actions. – Simply put, when an established critical limit at a designated critical control point (CCP) has been found not to be functioning as intended, thereby exposing consumers to potential food safety issues, design engineers must enact corrective measures to resolve the issue as soon as possible. Let’s return to the example set out in our last article, where we discussed HACCP Design Principle 4. An engineering manager has discovered a problem with the lower critical limits established by her design engineer’s software logic as it concerns a CCP established with regard to cooker temperature. The time and temperature in the logic create a hazardous situation by not taking into account that larger cuts of meat require more cooking time, resulting in them being undercooked. Fortunately, the engineering manager’s diligent and ongoing day-to-day monitoring has alerted her to the error. She immediately provides feedback about it to the design engineer, who makes corrections to the software logic. Problem solved, and all is working well within the food manufacturing plant, right? Yes, but we’re not finished. We have to make sure that a mechanism is set in place to ensure that HACCP Principles 1 through 5 are being followed and that they are actually working to protect consumers from potential food contamination hazards. Next time we’ll take a look at the last of the HACCP Design Principles, No. 6, which concerns itself with maintenance and housekeeping issues. ____________________________________________ |

Food Manufacturing Challenges – HACCP Design Principle No. 4

Sunday, November 6th, 2011| Imagine going on a diet and not having a scale to check your progress, or going to the doctor and not having your temperature taken. Feedback is important in our daily lives, and industry benefits by it, too.

Generally speaking, feedback, or monitoring, is a tool that provides relevant information on a timely basis as to whether things are working as they were intended to. It’s an indispensable tool within the food manufacturing industry. Without it, entire plants could be erected exposing workers to injury and consumers to bacteria-laden products. It’s just plain common sense to monitor activities all along the way, starting with the design process. Now let’s see how monitoring is applied in HACCP Design Principle No. 4. Principle 4: Establish critical control point monitoring requirements. – Monitoring activities are necessary to ensure that the critical limits established at each critical control point (CCP) established under Principle 3 discussed last week are working as intended. In other words, if the engineer identifies significant risks in the design of a piece of food processing equipment and establishes critical limits at CCPs to eliminate the risk, then the CCPs must be monitored to see if the risk has actually been eliminated. Monitoring can and should be performed in food manufacturing plants by a variety of personnel, including design engineers, the manager of the engineering department, production line workers, maintenance workers, and quality control inspectors. For example, engineering department procedures in a food manufacturing plant should require the engineering manager to monitor CCPs established by the staff during the design of food processing equipment and production lines. Monitoring would include reviewing the design engineer’s plans, checking things like assumptions made concerning processes, calculations, material selections, and proposed physical dimensions. In short, monitoring should be a part of nearly every process, starting with the review of design documents, mechanical and electrical drawings, validation test data for machine prototypes, and technical specifications for mechanical and electrical components. This monitoring would be conducted by the engineering manager during all phases of the design process and before the finished equipment is turned over to the production department to start production. To illustrate, suppose the engineering manager is reviewing the logic in a programmable controller for a cooker on a production line. She discovers a problem with the lower critical limits established by her engineer at a CCP in the design of a cooker temperature control loop. You see, the time and temperature in the logic is sufficient to thoroughly cook smaller cuts of meat in most of the products that will be made on the line, however the larger cuts will be undercooked. The time and temperature settings within the logic are insufficient to account for the difference. This situation illustrates the fact that monitoring does no good unless feedback is provided with immediacy. In our example, the design engineer who first established the CCP and the critical limits was not informed in a timely manner of the difference in cooking times that different size meats would require, resulting in the writing of erroneous software logic. Fortunately, continued monitoring by the engineering manager caught the error, leading her to provide feedback about it to the design engineer, who can then make the necessary corrections to the software. Next week we’ll see what design engineers do with the feedback they’ve received, as seen through the eyes of HACCP Principle 5, covering the establishment of corrective actions. |

Food Manufacturing Challenges – HACCP Design Principle No. 3

Sunday, October 30th, 2011| How do parents make life safer and healthier for their kids? One of the ways is to impose limits on things like roaming distance within the neighborhood, curfews, and insisting that you eat your vegetables. Just common sense, right? Let’s take a look at some more of it.

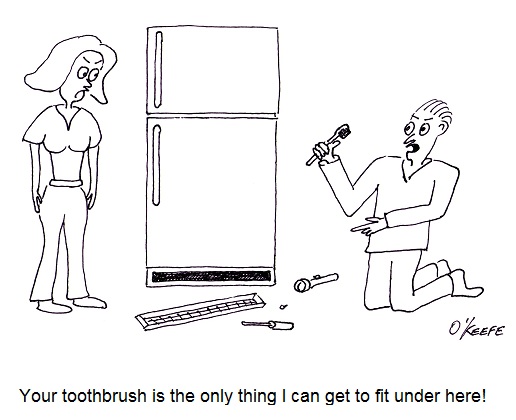

Limits are also necessary within the food manufacturing industry. Let’s take a look at Hazard Analysis and Critical Control Point (HACCP) Principle No. 3 to see how they’re established and why. Principle 3: Establish critical limits for each critical control point. – You can think of a critical limit as a boundary of safety for each critical control point (CCP). So how do you determine that boundary of safety? It’s difficult to generalize, but if you’ve ever watched the TV show Hoarders, you have an excellent example of one that has not only been breeched, but torn asunder. In order to prevent things in the commercial food industry from getting anywhere near Hoarders bad, maximum and minimum values are set in place, representing safeguards to physical, biological, and chemical parameters at play within the industry. Critical limits can be obtained from regulatory standards and guidelines, scientific literature, experimental studies, as well as information provided by consultants. These critical limits come into play with issues as varied as machine design, raw material temperatures, and overall safe processing times. How could the hoarders let things get so bad? If you listen carefully, you’ll hear bits of information that provide a clue. They’ll say it started with a few things falling to the floor which they didn’t feel like picking up and it escalated from there. Now all of us live within environments which differ as to their cleanliness, but by and large we live within space where we feel comfortable and consider to be reasonably clean. We don’t all habitually move stoves and refrigerators to clean, for example. But if we were so inclined, refrigerators do come with front access panels that are easily removed. Trouble is the space they provide access to often isn’t large enough to accommodate hands and a vacuum cleaner nozzle comfortably. You can imagine how frustrating and potentially dangerous it would be to public health to have commercial machinery that provided such limited access for cleaning. To cope with this problem design engineers institute minimum and maximum parameters, such as in the critical limit dimensions of a removable cover. Their guideline would ensure that enough space is provided so that personnel can fully access all aspects of machinery with tools for cleaning. That same cover can also have established maximum critical limits, so that dimensions aren’t too large and heavy to be manipulated by hand. Human nature being what it is, something that is too difficult to remove may be “forgotten” and parts of the machine may never get cleaned. Raw meats and many produce can contain hazards like salmonella, E. coli, and other nasty critters that are dangerous to human health. One of the ways the commercial food industry works to ensure that these contaminants aren’t unleashed on the public is to install programmable control systems into processing machinery that essentially cooks the meat at an established minimum temperature for a minimum amount of time. Utilizing this type of temperature control in conjunction with an established maximum cooking parameter for temperature and time will virtually eliminate the possibility of overcooked or burnt food products. When you buy that frozen dinner in most cases it’s completely cooked, but it’s a rarity to find it’s been burned. Another situation in which critical limits are utilized is in the maintenance of machinery, such as when they limit the number of hours a machine can be operated before it is shut down for servicing. Next week we’ll move on to Principle No. 4 and see how it establishes monitoring requirements for each CCP. ____________________________________________ |

Food Manufacturing Challenges – HACCP Design Principle No. 2

Sunday, October 23rd, 2011| What would you do if you heard an unfamiliar sound coming from your water heater? If you’re like most people you’d make a mental note to keep an eye on it, but ignore it for the most part. Unfortunately, this less than proactive approach often results in water heater floods. As an engineer, I’m more likely than the general population to investigate the cause of the water heater’s sound and proactively seek a remedy before a real problem has a chance to develop.

The FDA’s Hazard Analysis Critical Control Point (HACCP) seeks to accomplish the same with regard to food production. As discussed last week with regard to HACCP Principle 1, those involved in designing food processing equipment must proactively analyze designs to identify potential food safety hazards. Now let’s see how common sense is once again employed through Principle 2, guiding design engineers to take control of situations where hazards have been identified through Principle 1. HACCP Principle 2: Identify critical control points. A critical control point (CCP) is a step in the design process at which a control can be most effectively introduced to prevent or eliminate hazards. In this context a “control” would be a design revision to eliminate hazards identified during the Principle 1 stage. We will once again use the two examples introduced in last week’s blog discussion on Principle 1. In our first example, hazard analysis revealed that food can accumulate in a food processing machine in areas where cleaning is difficult or impossible. This accumulation would eventually rot and fall into uncontaminated food passing through production lines. Design engineers would work to address this contamination hazard by identifying a CCP within the design process, that is, the best place where a preventative measure can be added to the machine setup to facilitate removal of the accumulation. At that CCP, measures can be taken to change the machine’s design. Perhaps all that is needed to correct the situation is to include easy to remove access covers. In our second example hazard analysis revealed that the metal tooling as designed for our food production machine was too fragile and would not withstand the repeated forces imposed on it by the mass production process. This design flaw presents a strong possibility that metal parts will break off and enter food on the line. To correct this situation, design engineers must once again identify the juncture within the design process at which a CCP is identified. There, a preventative measure can most effectively be introduced, enabling more robust metal to be used in the tooling. The previous two examples illustrate CCPs being utilized within the design process. CCPs can also be introduced outside the design process, as when they are identified during the course of training procedures involving the operation, cleaning, and general maintenance of equipment and production lines. And an excellent way of implementing this approach is to have design engineers collaborate with operating and maintenance staff. Working together, they are best able to identify key elements to be addressed and make note of them within written procedures. Now that we have identified some examples of CCPs within the design process, we can move on to HACCP Principle 3 and how it guides design engineers to establish critical limits for each CCP.

|