|

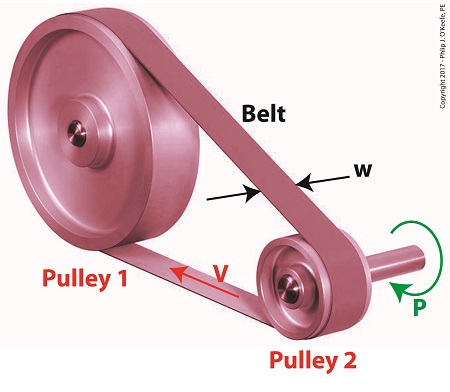

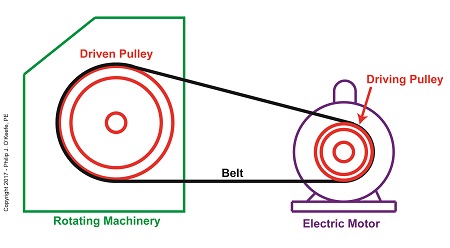

It’s been awhile since we began our discussion of a pulley-belt assembly operating within a hydroponics plant, and we’ve solved for a lot variables and derived many equations along the way. Today we’ll tackle the two remaining variables, T1 , the belt’s tight side tension, and T2 , its loose side tension, and we’ll determine exactly what belt width will optimize power transmission within our system. Optimizing Belt Width in a Pulley-Belt Assembly

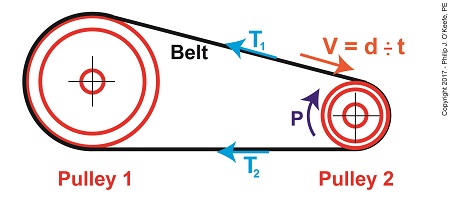

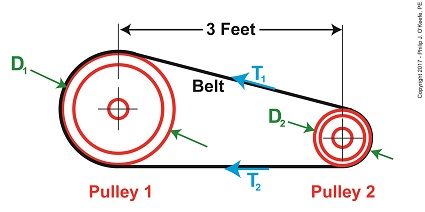

Last time we converted mechanical power, P, from horsepower into foot-pounds per second and the belt’s velocity, V, into feet per second in order to get things into terms we can work with. We then inserted these values into the mechanical power formula to get, 2,200 foot pounds per second = (T1 – T2) × 3.93 feet/second (1) This equation will allow us to solve for T1 and T2, and from there we’ll develop a value for the optimum belt width. Previously, we determined from the Euler-Eytelwein Formula that, T1 = 2.38T2 (2) Substituting equation (2) into equation (1), we get, 2,200 foot pounds per second = (2.38T2 – T2) × 3.93 feet/second (3) Reducing this equation with algebra we arrive at, T2 = 405.65 pounds (4) We can now insert equation (4) into equation (2) and calculate T1, T1 = 2.38 × 405.65 pounds (5) T1 = 965.44 pounds (6)

T1 is maximum tension in the belt, specified by the manufacturer to be 300 pounds per inch of width, which makes the minimum width belt to be used to optimize power transmission within our pulley-belt assembly, w = T1 ÷ 300 pounds per inch (7) w = 965.44 pounds ÷ 300 pounds per inch (8) w = 3.22 inches (9) We can use a belt of minimum width of 3.22 inches to safely transmit 4 horsepower from the engine to the pump without incurring breakage and slippage along the belt, thereby optimizing power transmission within our assembly. If we used a narrower belt, breaking and slippage would occur. If we used a wider belt, an unnecessary expense would be incurred. Next time we’ll begin a discussion on flywheels as they apply to rotating machinery like gasoline and steam engines.

Copyright 2017 – Philip J. O’Keefe, PE Engineering Expert Witness Blog ____________________________________ |