| Last week our kitchen ceiling fan and light combo decided to stop working. We don’t like eating in the dark, so I was compelled to do some immediate troubleshooting. As an engineer with training in the workings of electricity I have a great respect for it. I’m well aware of potential hazards, and I took a necessary precaution before taking things apart and disconnecting wires. I made the long haul down the stairs to the basement, opened the circuit breaker in the electrical panel, and disabled the flow of electricity to the kitchen. My fears of potential electrocution having been eliminated, my only remaining fear was of tumbling off the ladder while servicing the fan.

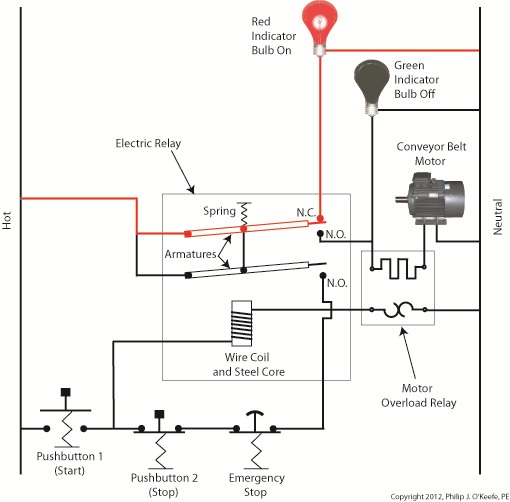

Just as I took the precaution to disconnect the power supply before performing electrical maintenance in my home, workers in industrial settings must do the same, and a chief player in those scenarios is the motor overload relay discussed last week. It automatically shuts down electric motors when they become overheated. Let’s revisit that example now. Figure 1

Our diagram in Figure 1 shows electric current flowing through the circuit by way of the red path. Even if this line were shut down, current would continue to flow along the path, because there is no means to disconnect the entire control system from the hot and neutral lines supplying power to it, that is, it is missing disconnect switches. Electric current will continue to pose a threat to workers were they to attempt a repair to the system. Now let’s see how we can eliminate potential hazards on the line. Figure 2

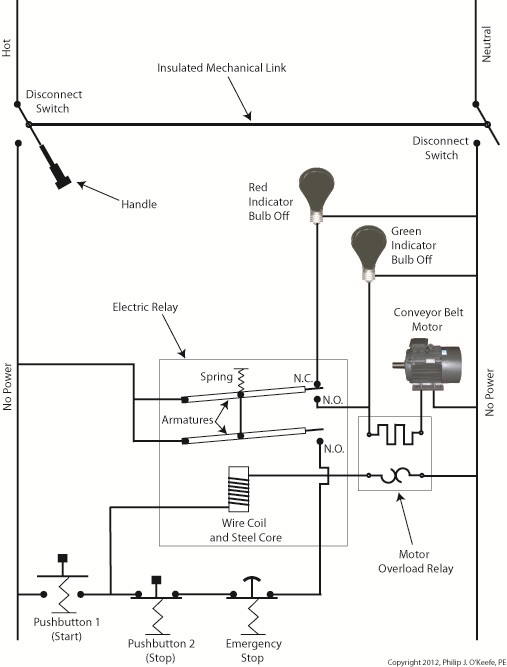

In Figure 2 there is an obvious absence of the color red, indicating the lack of current within the system. We accomplished this with the addition of disconnect switches capable of isolating the motor control circuitry, thereby cutting off the hot and neutral lines of the electrical power supply and along with it the unencumbered flow of electricity. These switches are basically the same as those seen in earlier diagrams in our series on industrial controls, the difference here is that the two switches are tied together by an insulated mechanical link. This link causes them to open and close at the same time. The switches are opened and closed manually via a handle. When the disconnect switches are both open electricity can’t flow and nothing can operate. Under these conditions there is no risk of a worker coming along and accidentally starting the conveyor motor. To add yet another level of safety, disconnect switches are often tagged and locked once de-energized. This prevents workers from mistakenly closing them and starting the conveyor while maintenance is being performed. Brightly colored tags alert everyone that maintenance is taking place and the switches must not be closed. The lock that performs this safety function is actually a padlock. It’s inserted through a hole in the switch handle, making it impossible for anyone to flip the switch. Tags and locks are usually placed on switches by maintenance personnel before repairs begin and are removed when work is completed. Now let’s see how our example control system looks in ladder diagram format. Figure 3

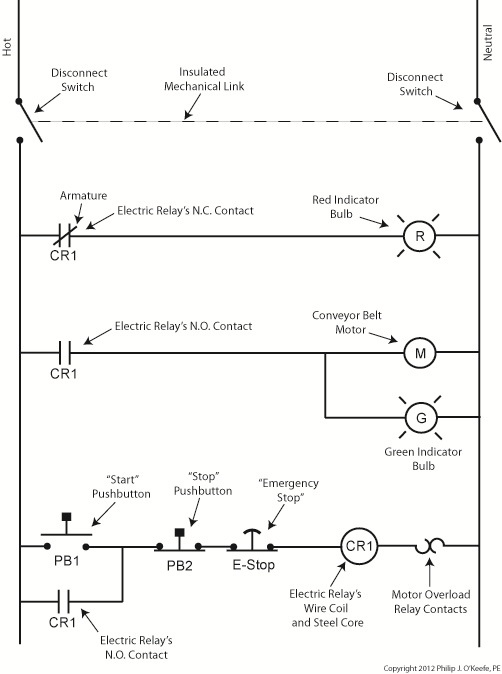

Figure 3 shows a ladder diagram that includes disconnect switches, an emergency stop button, and the motor overload relay contacts. The insulated mechanical link between the two switches is represented by a dashed line. Oddly enough, engineering convention has it that the motor overload relay heater is typically not shown in a ladder diagram, therefore it is not represented here. This wraps up our series on industrial control. Next time we’ll begin a discussion on mechanical clutches and how they’re used to transmit power from gasoline engines to tools like chainsaws and grass trimmers. ____________________________________________

|

Posts Tagged ‘electrocution’

Electrocution by Microwave Oven

Sunday, August 21st, 2011|

Ever been jolted with electric current? Like the time you’d just gotten out of the shower and went to plug in a lamp with damp hands? So what do you think the voltage was that caused that nasty biting feeling that resulted from your momentary lapse in good judgment? Once, while operating a subway car at a railroad museum at which I was a member, I was inadvertently “electrocuted.” I went to turn on the lights inside the car, and unbeknownst to me the light switch was faulty. When I touched it I instantly became connected to the car’s 600 volt lighting circuit. With just a split second of contact the current passed through the tip of my right index finger, along my right arm, down the right side of my body, and out the tip of my big toe, finally exiting into the metal railcar’s body. The current actually burned a hole where it had exited through my boot. The experience was both frightening and painful, but fortunately did not result in any real injury. I was lucky that the current had bypassed my heart, because if it hadn’t, I might not be alive today. That was 600 volts. Now imagine being jolted by the 4000 volts present in a microwave oven’s internal high voltage circuitry. Last week we discovered how the high voltage circuit in a microwave oven converts the ordinary, everyday 120 volts alternating current (AC) present in our homes into a much higher voltage approximating direct current (DC). This is done by an internal component known as the capacitor. The capacitor is capable of storing large amounts of electrical energy, and this can result in microwave ovens presenting a danger even when unplugged. A microwave oven capacitor is shown in Figure 1. If you happened to touch its wire terminals while it’s still charged, its power can rapidly discharge high voltage electrical current throughout your body. The electrical current from the capacitor can even stop your heart from beating, and this is exactly what caused the demise of a person featured on a soon to be released Discovery Channel program, Curious and Unusual Deaths. While being interviewed as an expert for the program, I was asked to explain this rather unique phenomenon of latent stored energy, and how it may present a threat. Figure 1 – A Microwave Oven Capacitor Remember, a microwave oven capacitor can remain charged with dangerous electrical energy for hours, even days, after the microwave oven plug is pulled from the wall outlet. The bottom line here is that you should not attempt to fix your microwave oven, unless you are trained and certified to do so. Next week we’ll switch to a different topic, namely an electrical device known as a “wall wart.” That’s the black plastic adapter you plug into electrical outlets to power your cell phones, laptops, and other small electronics. ____________________________________________ |

The Microwave Oven — More on How AC Becomes DC

Monday, August 15th, 2011| The world of electricity is full of mysteries and often unanticipated outcomes, and if you’ve been reading along with my blog series you have been able to appreciate and come to some understanding of a fair number of them. This week’s installment will be no exception.

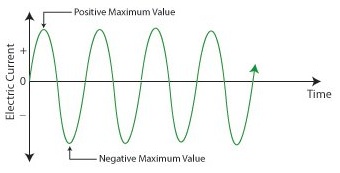

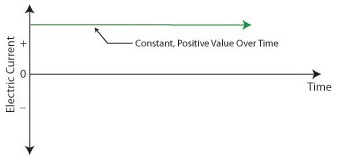

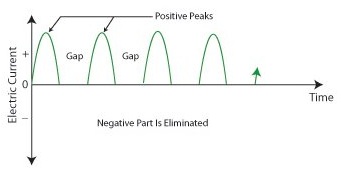

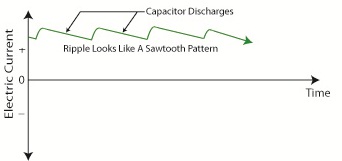

Last week we looked briefly at the high voltage circuit within a microwave oven. We discovered that the circuit contains a transformer that raises 120 volts alternating current (AC) to a much higher voltage, around 4000 volts AC. The circuit then transforms the AC into direct current (DC) with the help of electronic components known as a diode and capacitor. Let’s take a closer look at how the diode and capacitor work together to make AC into DC. Let’s follow an AC wave with the aid of a device called an oscilloscope. An oscilloscope takes in an electronic signal, measures it, graphs it, and shows it on a display screen so you can see how the signal changes over time. An AC wave is shown in Figure 1 as it would appear on an oscilloscope. Figure 1 – Alternating Current Wave You can see that each wave cycle starts with a zero value, climbs to a positive maximum value, then back to zero, and finally back down to a maximum negative value. The current keeps alternating between positive and negative polarity, hence the name “alternating current.” Within the microwave oven’s high voltage circuitry the transformer does the job of changing, or transforming if you will, 120 volts AC into 4000 volts AC. This high voltage is needed to make electrons leave the cathode in the magnetron and move them towards the anode to generate microwaves. But we’re not done with the transformation process yet. The magnetron requires DC to operate, not AC. DC current remains constant over time, maintaining a consistent positive value as shown in Figure 2. It is this type of consistency that the magnetron needs to operate. Figure 2 – Direct Current The microwave’s diode and capacitor work together to convert the 4000 volts AC into something which resembles 4000 volts DC. First the diode acts like a one-way valve, passing the flow of positive electric current and blocking the flow of negative current. It effectively chops off the negative part of the AC wave, leaving only positive peaks, as shown in Figure 3. Figure 3 – The Diode Chops Off The Negative Part of the AC Wave Between the peaks are gaps where there is zero current, and this is when the capacitor comes into play. Capacitors are similar to batteries because they can be charged with electrical energy and then discharge that energy when needed. Unlike a battery, the capacitor charges and discharges very quickly, within a fraction of a second. Within the circuitry of a microwave oven the capacitor charges up at the top of each peak in Figure 3, then, when the current drops to zero inside the gaps the capacitor comes into play, discharging its electrical energy into the high voltage circuit. The result is an elimination of the zero current gaps. The capacitor acts as a reserve energy supply to fill in the gaps between the peaks and keep current continually flowing to the magnetron. We have now witnessed a mock DC current situation being created, and the result is shown in Figure 4. Figure 4 – The Capacitor Discharges to Fill In The Gaps Between Peaks The output of this approximated DC current looks like a sawtooth pattern instead of the straight line of a true DC current shown in Figure 2. This ripple pattern is evidence of the “hoax” that has been played with the AC current. The net result is that the modified AC current, thanks to the introduction of the diode and energy storing capacitor, has made an effective enough approximation of DC current to allow our magnetron to get to work jostling electrons loose from the cathode and putting our microwave oven into action. You now have a basic understanding of how to turn AC into an effective approximation of DC current. Next week we’ll find out how this high voltage circuit can prove to be lethal, even when the microwave oven is unplugged. ____________________________________________ |

The Microwave Oven High Voltage Circuit—How AC Becomes DC

Sunday, August 7th, 2011| My mom was a female do-it-yourselfer. Toaster on the blink? Garbage disposal grind to a halt? She’d take them apart and start investigating why. Putting safety first, she always pulled the plug on electrical appliances before working on them. Little did she know that this safety precaution would not be enough in the case of a microwave oven. Let’s see how even an unplugged microwave can prove to be a lethal weapon and, yes, we’re going to have to get technical.

Last week we talked about the magnetron and how it needs thousands of volts to operate. To get this high of a voltage out of a 120 volt wall outlet–the voltage that most kitchen outlets provide–the microwave oven is equipped with electrical circuitry containing three important components: a transformer, a diode, and a capacitor, and just like the third rail of an electric railway system these items are to be avoided. If you decide to take your microwave oven apart and you come into contact with high voltage that is still present, you run the risk of injury or even death. But how can high voltage be present when it’s unplugged? Read on. First we need to understand how the 120 volts emitting from your wall outlet becomes the 4000 volts required to power a microwave’s magnetron. This change takes place thanks to a near magical act performed by AC, or alternating current. In the case of our microwave components, specifically its diode and capacitor, AC is made to effectively mimic the power of DC, or direct current, the type of current a magnetron needs. This transformation is made possible through the storage of electrical energy within the microwave’s capacitor. Next week we’ll examine in detail how this transformation from AC to DC current takes place, as seen through a device called an oscilloscope. ____________________________________________ |

The Microwave Oven Becomes Reality

Sunday, July 31st, 2011| The evolution of cooking methods has been interesting indeed, from the open fires of primitive man, who must have decided at some point that cooked meat tasted better than raw, on to wood fired stoves, fossil fuel-based cooking, whether coal, propane, or gas, and let’s not forget electric range tops. Standing on its own in the modern kitchen is the microwave oven. What will be next? The space age food pill dispensing stations of the futuristic cartoon family, The Jetsons?

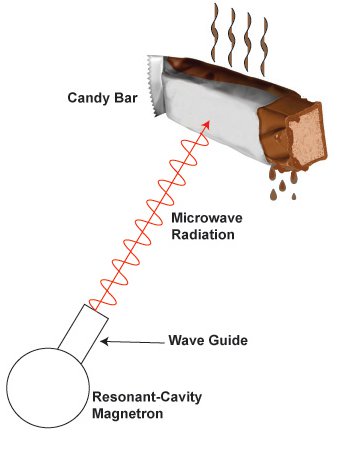

We’ve been talking about resonant cavity magnetrons and the purpose they serve within a microwave radar system. We also learned about Dr. Percy Spencer’s discovery and how microwave radar transmissions emanating from a magnetron can cook food, not to mention melt candy bars. Figure 1- Microwaves Melt Candy Bars and Cook Food Although the technologies used in microwave radars and microwave ovens are similar, they do have important differences. It would be both unsafe and impractical to install microwave radar systems into kitchens. Radiation emitted from radar wave guide lacking proper containment would bounce aimlessly around the kitchen, posing a threat to human safety. You see, microwaves don’t know the difference between our bodies and the food we wish to cook. They’ll heat up human tissue just as readily as a bowl of chicken soup. Another issue is that runaway microwaves lose much of their effectiveness through their aimless bouncing about, and much of it would not be directed to the food itself. Dr. Spencer would learn how to corral that energy, making microwave cooking a commercial success. The biggest problem for Dr. Spencer to overcome was containment of the microwaves. They needed to be directed towards food in order to efficiently heat them. His first microwave oven was a metal box containing an opening at the top into which a magnetron wave guide could be inserted. This would then introduce microwaves into the box, and the metal construction of the box would safely contain them. The safety issue had now been resolved because the waves couldn’t escape, they would simply bounce around inside the box and most of their energy would be transferred into any food placed inside. Dr. Spencer’s employer, the Raytheon Corporation, produced the first commercial microwave oven in 1954, and it was appropriately named the “Radarange.” It was huge, almost six feet tall, and weighed in at about 750 pounds! Hardly something that could fit into a home kitchen. Despite its massive size, the Radarange wasn’t all that powerful and couldn’t compete against the compact countertop microwave ovens in use today. It wasn’t until 1967 that technology improved enough to give us the smaller, more efficient units affordable to consumers. This improvement involved using a newly developed semiconductor device called a “diode” within the high voltage electric circuitry that powers the magnetron. We’ll learn more about these technologies in our next post. Also in our next post, we’ll see how high voltage circuits can pose electrocution hazards in a way you‘d never expect. I discussed one of these instances in my recent appearance on The Discovery Channel program, Curious and Unusual Deaths, soon to be aired. _____________________________________________ |

GFCI Outlets and The Mighty Robot

Sunday, July 3rd, 2011Ground Fault Circuit Interrupters

Sunday, June 26th, 2011| I’ve been talking about how I was asked to be a subject matter expert for an upcoming series on The Discovery Channel titled Curious and Unusual Deaths. Most of the accidents discussed involved electrocutions, and in each case the electrocution occurred because the victim’s body, usually their hand, inadvertently contacted a source of current. When that happened their bodies essentially became like a wire, providing an unintended path for current to travel on its way to the ground. Why does it travel to the ground, you ask? Because electric current, by its very nature, always wants to flow along a conductor of electricity from a higher voltage to a lower voltage. The ground is the lowest voltage area on our planet. When electricity flows to ground along an unintended path it’s referred to as a “ground fault,” because that’s where the electricity is headed, to the ground, or Earth. By “fault” I mean that something in an electrical circuit is broken or not right, allowing the electrical current to leak out of the circuit along an unintended path, like through a person’s body.

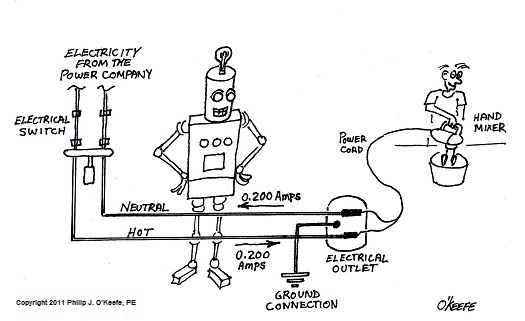

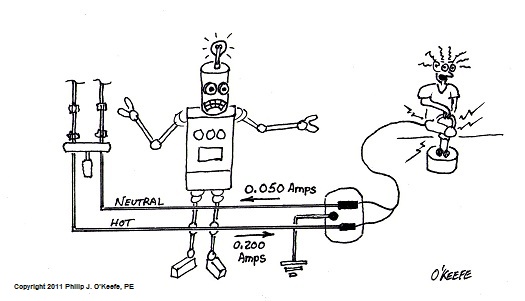

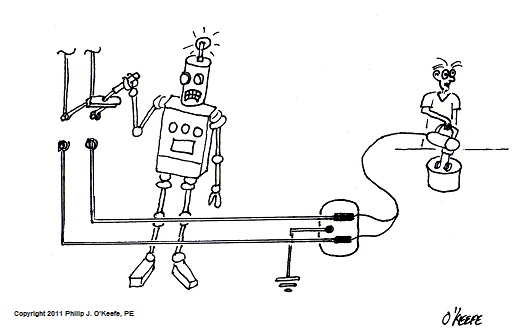

For example, in one of the Curious and Unusual Deaths segments I was asked to explain how a fault in wiring caused electrical current to flow through a woman’s body to the ground that she was standing on. This happened when she unintentionally came in contact with a metal door that was, unbeknownst to her, electrically charged from an unanticipated source. The current was strong enough to cause her death. Where did the electric current originate from? Watch the program to find out, but I’m sure you’d never guess. To say that it was an unlikely source is an understatement. When ground faults pass through a person’s body, bad things often happen, ranging from a stinging shock to stopping your heart muscle to burning you from the inside out. The severity depends on a number of factors, including the strength of the current to the amount of time your body is exposed to it. It might surprise you to know that if your skin is wet at the time of contacting a current, you risk a greater chance of injury. Water, from most sources, contains dissolved minerals, making it a great conductor of electricity. But what exactly is electrical current? Scientifically speaking it’s the rate of flow of electrons through a conductor of electricity. Let’s take a closer look at a subject close to home, a power cord leading from a wall’s outlet to the electric motor in your kitchen hand mixer. That power cord contains two wires. In the electrical world one wire is said to be “hot” while the other is “neutral.” The mixer whirrs away while you whip up a batch of chocolate frosting because electrons flow into its motor from the outlet through the hot wire, causing the beaters to spin. The electrons then safely flow back out of the motor to the wall outlet through the neutral wire. Now normally the number of electrons flowing into the motor through the hot wire will basically equal the number flowing out through the neutral wire, and this is a good thing. When current flow going in equals current flow going out, we end up enjoying a delicious chocolate cake. Since the human body can conduct electricity, serious consequences may result if there is an electrical defect in our hand mixer that creates a ground fault through the operator’s body while they are using it. In that situation the flow of electrons coming into the mixer from the hot wire will begin to flow through the operator’s body rather than flowing through the neutral wire. The result is that the number of electrons flowing through the hot wire does not equal the flow of electrons flowing through the neutral wire. Electrons are leaking out of what should be a closed system, entering the operator’s body instead while on its way to find the ground. Next time we’ll look at a handy device called a Ground Fault Circuit Interrupter (GFCI) and how it keeps an eye on the flow of electrons, which in turn keeps us safe from being electrocuted. _____________________________________________ |

Green Screens and Makeup Chairs

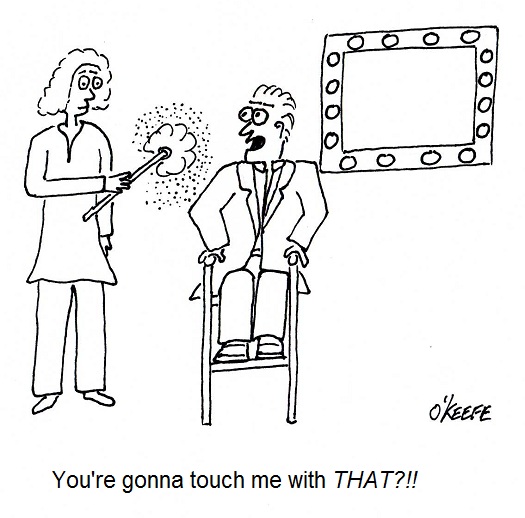

Monday, June 20th, 2011| Imagine being a typical guy, the kind that hates to shave and would never dream of wearing anything that even remotely resembles makeup. That was me, before being contacted by The Discovery Channel to act as a subject matter expert on the topic of steam power plants and electrocutions, part of a series they’ll be airing in the near future to be called Curious and Unusual Deaths. Little did I know when agreeing to appear on the program that I was also agreeing to venture into an area of human experience most males would like left to the females, that of donning facial makeup.

Upon my arrival in Toronto to meet up with the producers I was treated like a celebrity. A chauffer had been sent to greet me at the airport, and I was driven to a fancy downtown hotel. The next morning I was driven to the video studio and spent some time in the makeup chair to get gussied up. My imperfections muffled, I was invited to take a seat in front of a green screen, and for those of you who don’t know what the function of this marvel of photography is, let me briefly explain. The green screen enables the editors to digitally impose any kind of background behind me at a later time of their choosing, anything from the Grand Canyon to footage of World War II. As of this time I have no idea what images will be shown in back of me as I speak. It’ll be interesting to see where I end up! Once the cameras and lights were adjusted in the studio, there was a clack from the director’s clapper board, accompanied by a shout of “roll ‘em!” And we were off shooting, just like in Hollywood. Two video cameras shot me simultaneously, one placed directly in front and one to my left. One of the show’s producers sat next to the front-positioned video camera during shooting. She needed to be within earshot, because she soon proceeded to ask me pointed questions about the science behind each incident being investigated. It was up to me to ad-lib the responses, bearing in mind that the subject matter was technical and had to be conveyed to an audience of average technical background in a manner in which they could understand it. Every now and then we’d take a break from filming so the crew could tend to the video equipment. It seems that adjustments had to be continually made to both cameras and lighting. Videotapes had to be changed, and the makeup artist would use these as opportunities to tweak my makeup. All in all it was an enjoyable experience. Everyone acted professionally and was easy to work with, and the producers expressed their satisfaction with the part I had played. I was told that I explained the technical subject matter in a way that anyone could understand, and I thanked them. But after all, as I shared with them, that’s my job! It was nice to hear that I was doing it well. Next time we’ll get into how GFCI outlets help to prevent you from getting electrocuted and from becoming a potential subject on Curious and Unusual Deaths. _____________________________________________ |